Special casting mold for double-floating ring blank of floating oil seal

A floating oil seal, casting mold technology, applied in the field of casting molds, can solve the problems of poor quality and low qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

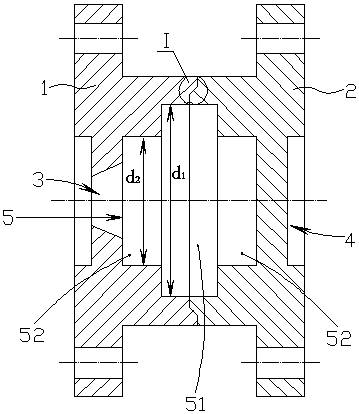

[0012] see figure 1 , figure 2 , the special casting mold for floating oil seal double floating ring billet of the present invention comprises matching left and right disc-shaped half-molds 1, 2, the left disc-shaped half-mold 1 has a casting material inlet 3, and the right side The disc-shaped half-mold 2 has a transmission shaft installation positioning groove 4. When the disc-shaped half-molds 1 and 2 on the left and right sides are opposed to each other, a cross-section communicating with the casting material inlet 3 is formed inside. Circular mold cavity 5 along the axial direction of the disc-shaped half molds on both sides of the left and right sides. The radial dimension d of the mold chamber 51 1 Greater than the radial dimension d of the mold chambers 52 on both sides 2 .

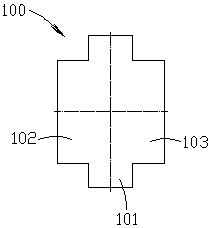

[0013] see you again image 3 , Figure 4 , image 3 It is a schematic diagram of the front view of the floating oil seal double floating ring blank 100 cast by the casting mold of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com