Efficient environment-friendly white cement production method

A production method, white cement technology, applied in cement production, separation methods, chemical instruments and methods, etc., can solve the problems of high coal ash content, high price, low calorific value, etc., to improve production efficiency, improve qualification, and obtain simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

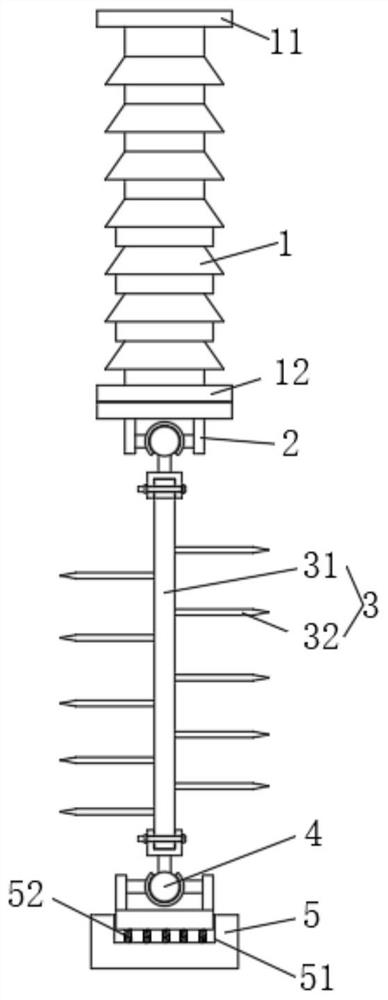

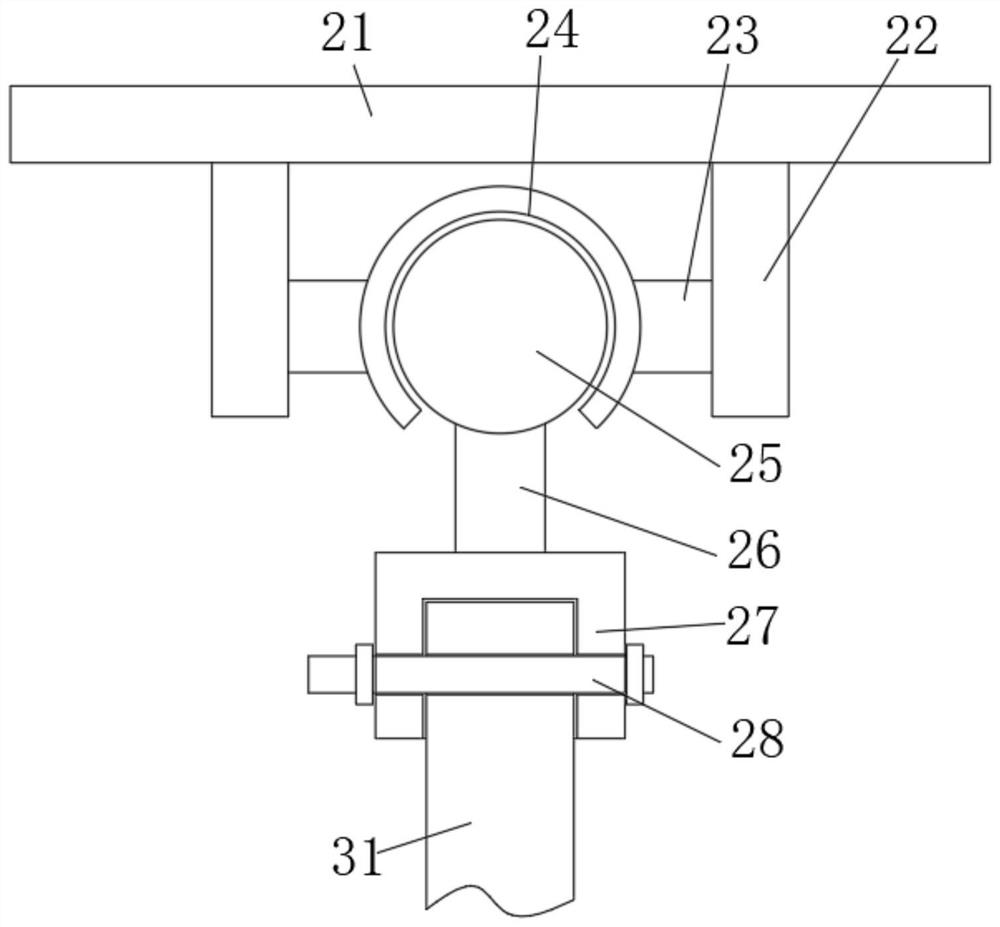

Image

Examples

Embodiment 1

[0048] The bleached clinker, additives, and high-quality natural gypsum are respectively discharged into the corresponding batching scales for quantitative weighing;

[0049] The clinker, additives and retarder are transported to the cement mill and mixed to produce white cement material.

Embodiment 2

[0051] The bleached clinker, additives, and desulfurized gypsum are respectively discharged into corresponding batching scales for quantitative weighing; the Hunter whiteness of the desulfurized gypsum is ≥86, and the SO in the desulfurized gypsum 3 content ≥ 40%, calcium sulfite content ≤ 10%, chloride ion content ≤ 0.02%, the desulfurization gypsum is in a slurry state, and its water content is controlled at 20-40% by low-temperature drying; whiteness control is to ensure White cement product quality; SO 3 The control is used to reduce air pollution; the control of calcium sulfite and chloride ions is used to avoid the impact on the strength of cement, the performance of setting time and the application of cement; the control of water content is to ensure the normal transportation and mixing of materials, too much water will affect Conveying efficiency and mixing effect; these are important parameters for preparing qualified white cement;

[0052]The clinker, additives and ...

Embodiment 3

[0055] The bleached clinker, additives, and salt gypsum are respectively discharged into corresponding batching scales for quantitative weighing; the Hunter whiteness of the salt gypsum is ≥90, and the SO in the salt gypsum 3 content ≥ 40%, calcium sulfite content ≤ 10%, chloride ion content ≤ 0.02%, the salt gypsum is in a slurry state, and its water content is controlled at 20-40% by low-temperature drying; whiteness control is to ensure White cement product quality; SO 3 The control is used to reduce air pollution; the control of calcium sulfite and chloride ions is used to avoid the impact on the strength of cement, the performance of setting time and the application of cement; the control of water content is to ensure the normal transportation and mixing of materials, too much water will affect Conveying efficiency and mixing effect; these are important parameters for preparing qualified white cement;

[0056] The clinker, additives and retarder are transported to the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com