Cutting liquid recycling equipment and recycling method thereof

A technology for recycling equipment and cutting fluid, applied in cutting fluid recycling equipment and its recycling field, can solve the problems of waste liquid sewage discharge, peeling, cutting fluid odor, etc., to reduce human resources, improve processing efficiency, and reduce emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

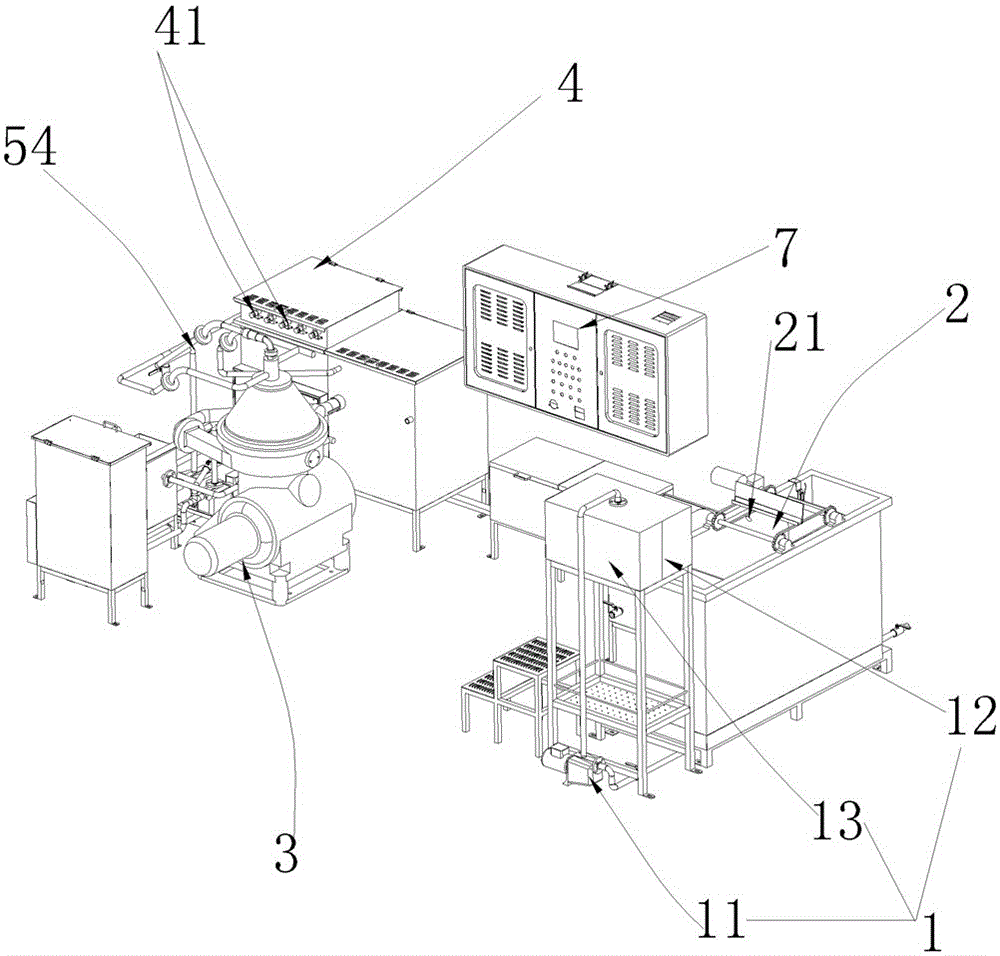

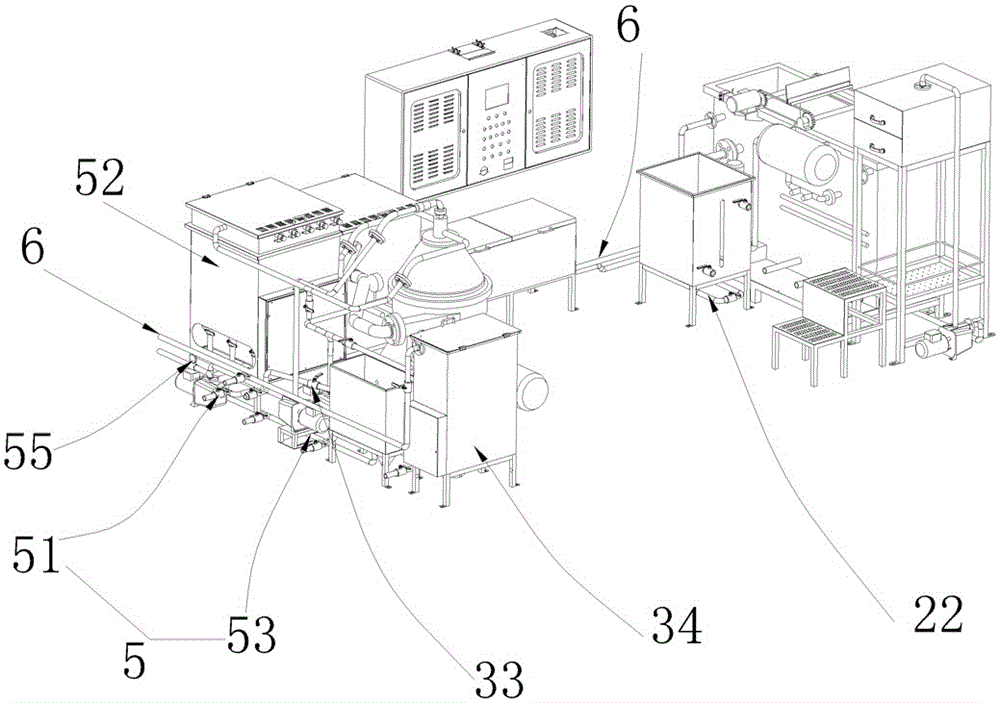

[0047] see Figure 1-2, the cutting fluid recycling equipment provided by the present invention includes an automatic feeding device 1, a dissolved air flotation machine 2, a high-speed centrifuge 3, a UV photolysis sterilization device 4, an automatic discharging device 5 and a PLC controller (not shown in the figure) ); the automatic feeding device 1 is provided with a feed pump 11 and a feed transfer box 13 with a filter screen 12 inside, and the automatic discharge device 5 is provided with a discharge pump 51 and a discharge box 52, and the feed pump 11 and discharge pump 51 are electrically connected with the output end of the PLC controller respectively;

[0048] The feed pump 11 feeds the waste cutting fluid into the feed transfer box 13 and passes through the filter screen 12 to roughly filter the coarse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com