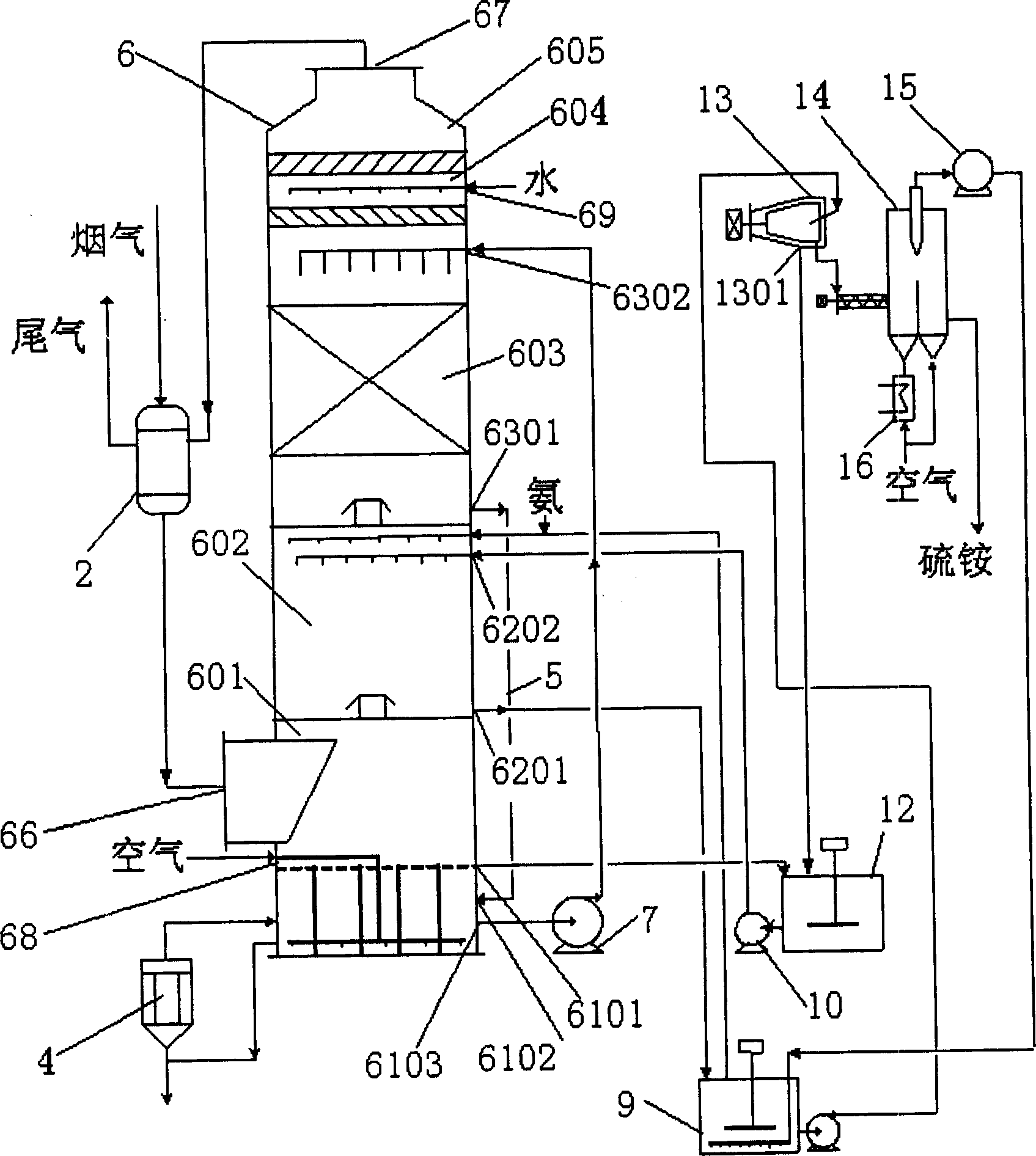

Removing and recovering process and device for SO2 in flue gas

A recovery method, SO2 technology, applied in chemical instruments and methods, separation methods, ammonium sulfate, etc., to achieve the effects of convenient operation, reduced steam consumption, and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

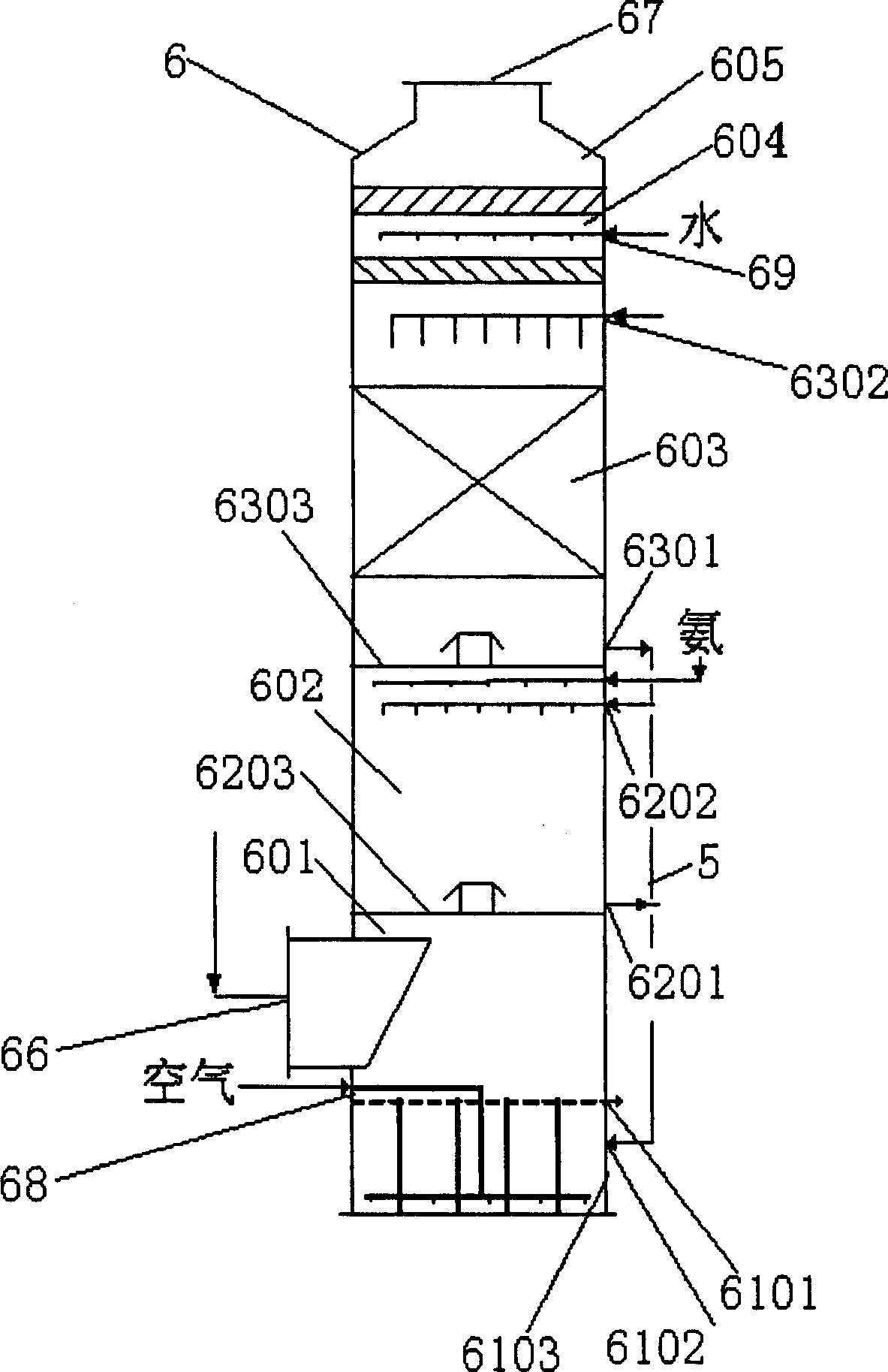

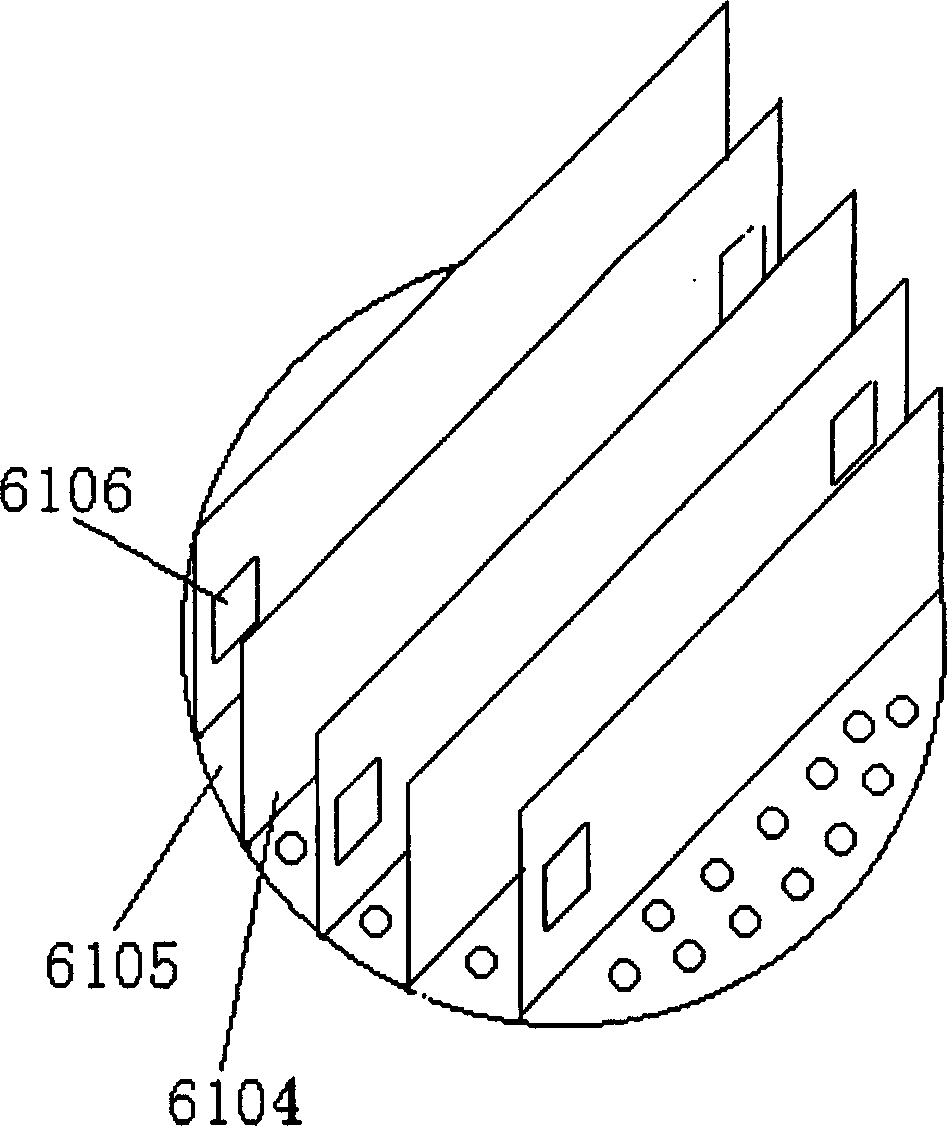

Method used

Image

Examples

Embodiment 1

[0077] A 220T / h coal-fired thermoelectric boiler with a flue gas flow rate of 250,000 Nm 3 / hr, SO 2 The content is 1500mg / Nm 3 , the dust content of flue gas is 80mg / Nm 3 , the flue gas temperature is 140°C. The desulfurization tower 6 has a diameter of 6m and a height of 28m. The reheater 2 is a heat pipe type. After the flue gas passes through the reheater 2, the temperature drops to 110°C and enters the desulfurization tower 6. When leaving the desulfurization tower, the SO in the desulfurization tail gas 2 The content is 20mg / Nm 3 , NH 3 The content is 1mg / Nm 3 , the water foam content is 96mg / Nm 3 .

[0078] The absorption section adopts 100m 2 / m 3 The polypropylene structured orifice corrugated packing, the absorption liquid flow rate is 100m 3 / hr, the ammonium sulfite content is 7.5% (wt), and when leaving the absorption section, the ammonium sulfite concentration is 0.6% (wt).

[0079] In the absorption section, the amount of ammonia intake is 1.45 acco...

Embodiment 2

[0082] A 670T / h thermal power generation unit, namely 200MW, burns coal with a sulfur content between 1.5-2.0%, and the flue gas flow rate is 800,000 Nm 3 / hr, SO 2 The content is 4200mg / Nm 3 , the electrostatic precipitator is 3 electric fields, and the dust content of the flue gas is 200mg / Nm 3 , the flue gas temperature is 145°C. The desulfurization tower 6 has a diameter of 10 m and a height of 30 m.

[0083] The reheater 2 is a rotary heat storage type. After the flue gas passes through the reheater, the temperature drops to 116°C and enters the desulfurization tower. When leaving the desulfurization tower, the SO in the desulfurization tail gas 2 The content is 34mg / Nm 3 , NH 3 The content is 1mg / Nm 3 , the water foam content is 125mg / Nm 3 .

[0084] The absorption section adopts 125m 2 / m 3 The polypropylene structured orifice corrugated packing, the absorption liquid flow rate is 400m 3 / hr, the ammonium sulfite content is 17.3% (wt), and when leaving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com