INS film laminated product production process and diaphragm sliding block fixing mechanism during injection molding

A technology of fixing mechanism and production process, applied in the direction of coating, etc., can solve the problems of mold clamping, crimping and overwrapping, product scrapping, difficult positioning, etc., and achieve the effect of improving product qualification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

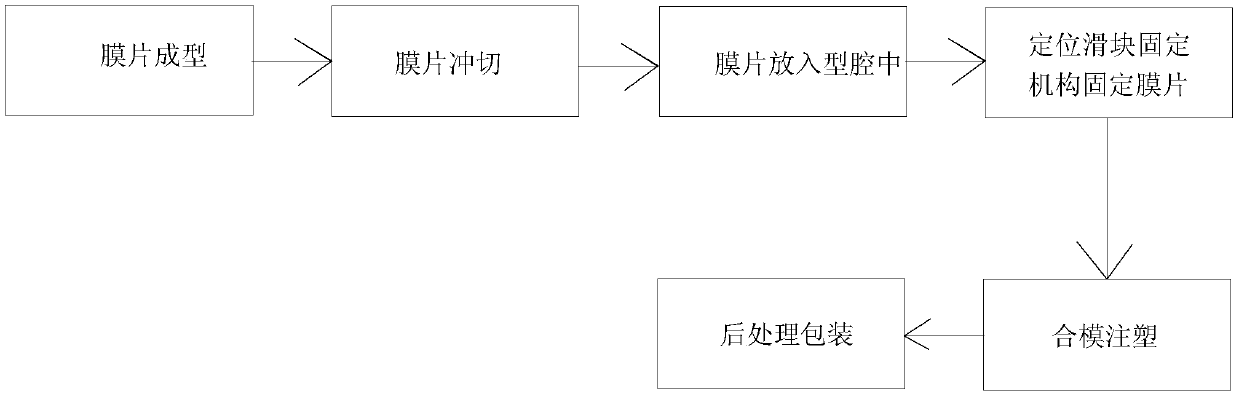

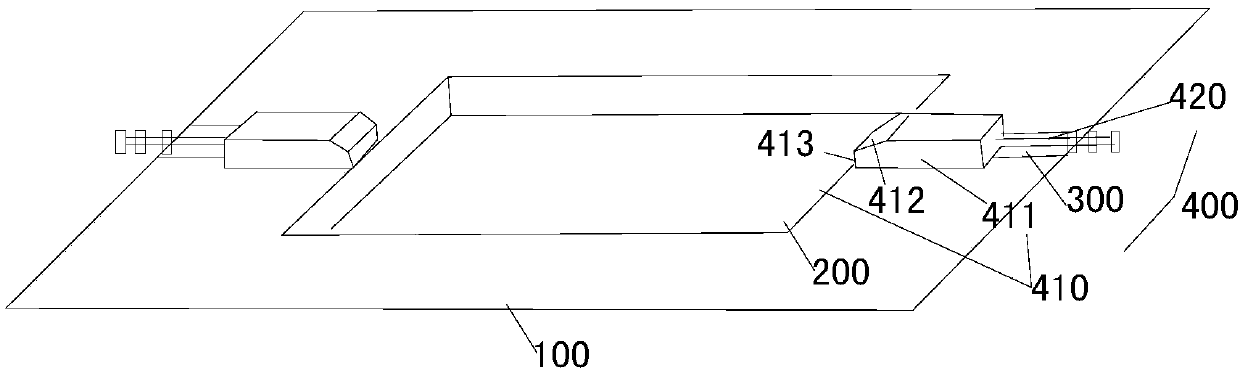

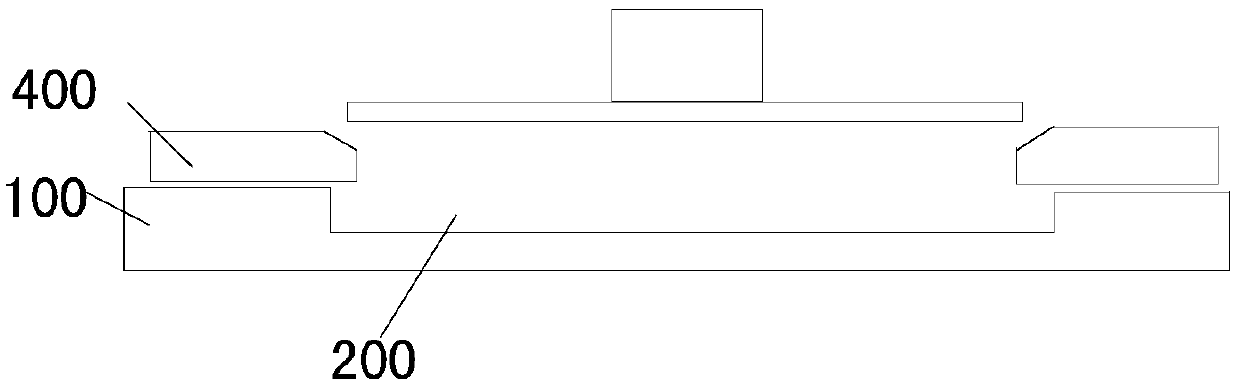

[0023] figure 1 It is a process flow diagram of the present invention. figure 2 It is the structural diagram of the fixed mechanism. image 3 It is the use state diagram of the fixing mechanism.

[0024] Such as figure 1 As shown, the INS film-coated product production process is characterized in that it includes:

[0025] Step 1: Membrane forming, forming the rolled membrane by blister, and then blistering into the shape of the product wrapping;

[0026] Step 2: Diaphragm die-cutting, put the vacuum-formed diaphragm on the lower mold core of the die-cutting mold for die-cutting, die-cut off the excess sheet, leave the area of the diaphragm that needs to be coated, and punch-cut Good film transfer to the injection molding area;

[0027] Step 3: Put the diaphragm into the cavity, wipe the cut diaphragm clean and put it into the cavity of the injection mold;

[0028] Step 4: The diaphragm is fixed by the positioning slider fixing mechanism, and the diaphragm is put into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com