Concrete distributing device for heat-insulating integrated wall pouring, and pouring method

A distribution device and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of insufficient thickness of outer wall protection layer, offset of insulation board, honeycomb pockmarked surface, etc., and achieve strong operability of connection and disassembly , processing and welding is convenient, the effect of green construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

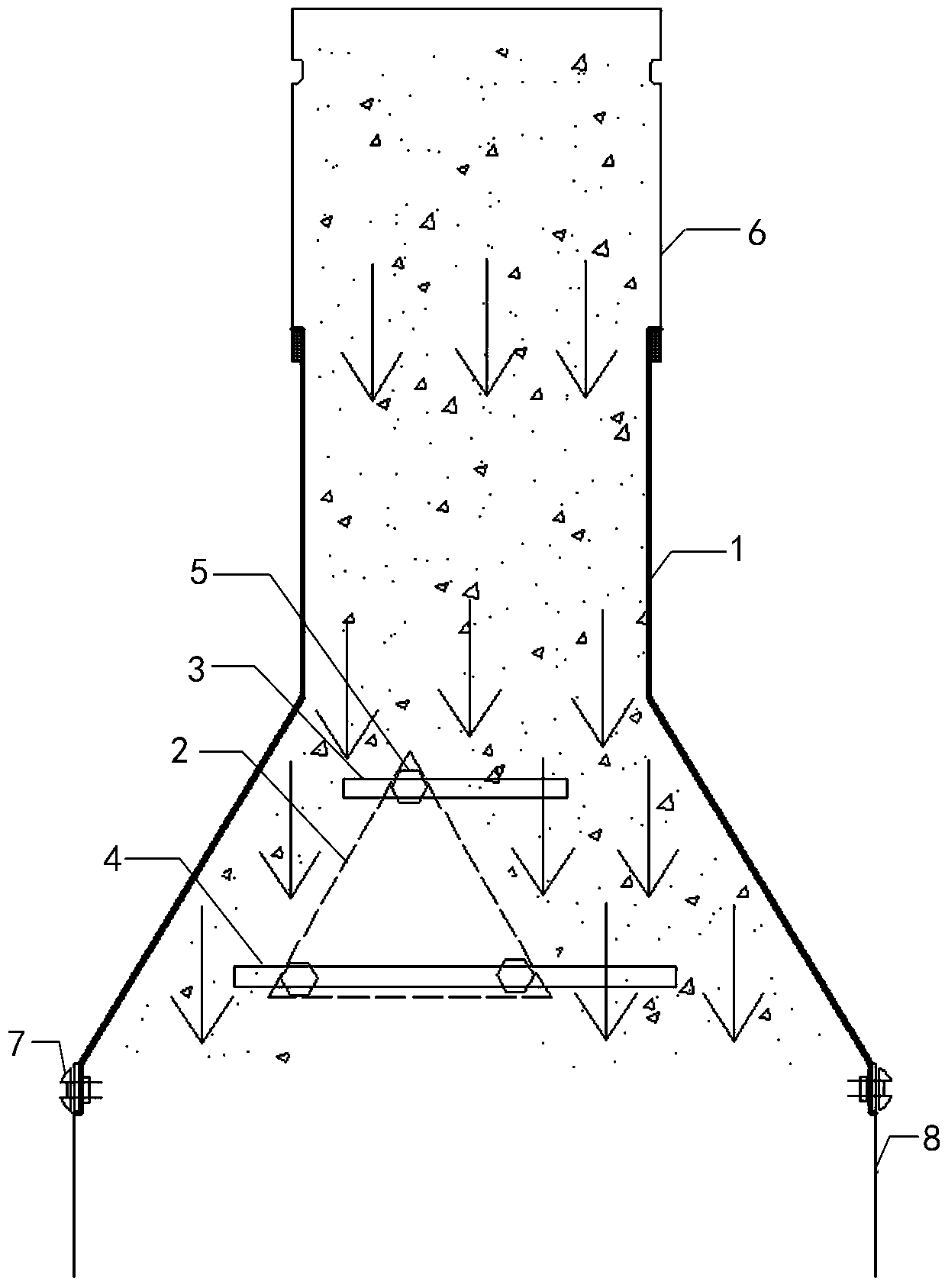

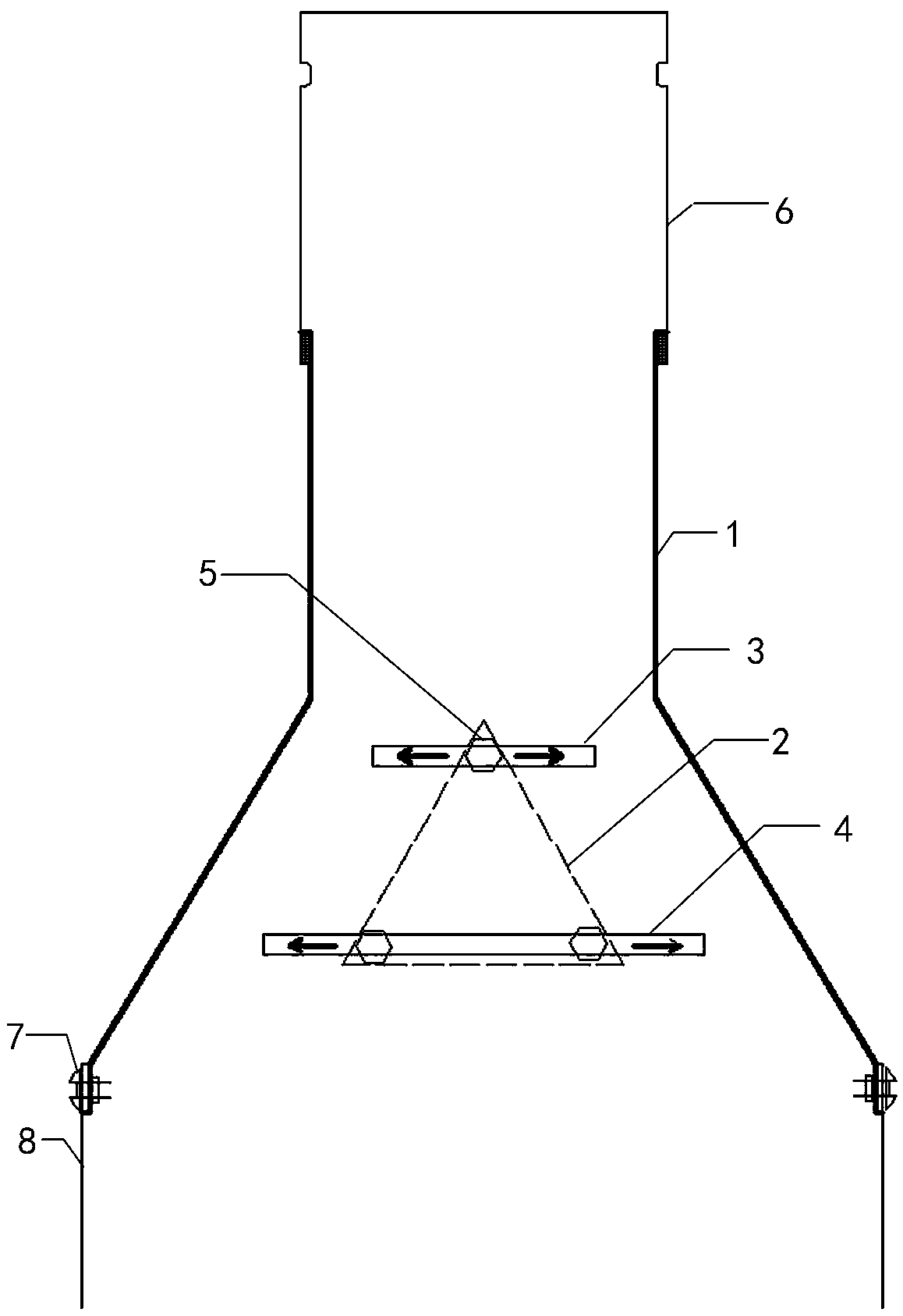

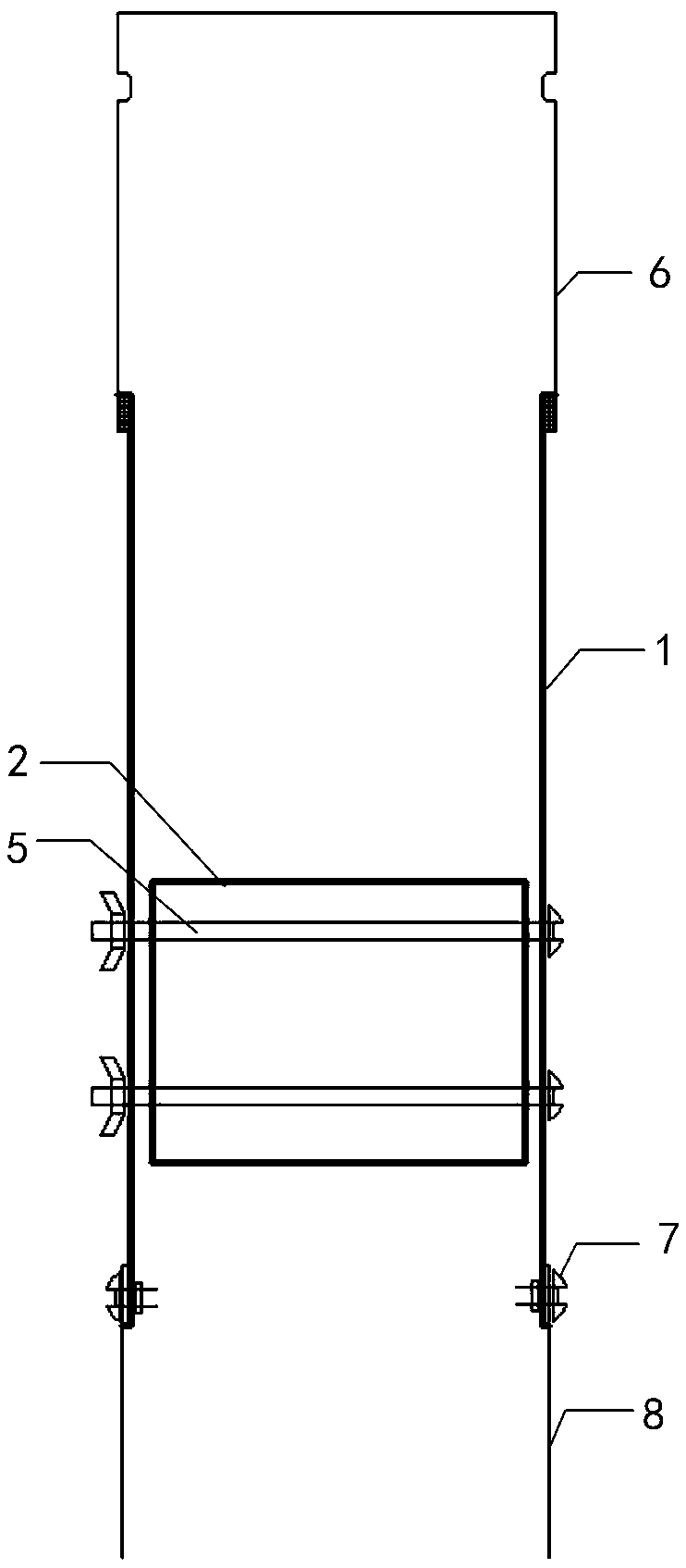

[0044] see Figure 1-Figure 4 As shown, a concrete distribution device and its pouring method for thermal insulation integrated wall pouring, the total height of the concrete distribution device for thermal insulation integrated wall pouring including the pump pipe interface and rubber baffle is 575mm, wherein the pump pipe interface The height of the rubber baffle is 150mm, the height of the rubber baffle is 100mm, the height of the shell is 325mm, the width of the upper opening is 150mm, and the width of the lower opening is 320mm; it is set directly above the thermal insulation integrated wall, including the shell 1 and the Movable dispenser 2 in housing 1; see Figure 6As shown, the housing 1 includes two parts, an upper part and a lower part. The upper part is a cylindrical cylinder made of a steel sleeve with a wall thickness of 5mm. The opposite side is a vertical surface, the other pair of side surfaces is an outwardly inclined slope, and a circular through hole is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com