Complex-frequency ultrasound-assisted turning device

An ultrasonic-assisted and turning technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of complicated installation, high cost, complicated operation, etc., and achieve the effect of saving processing cost, simple installation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

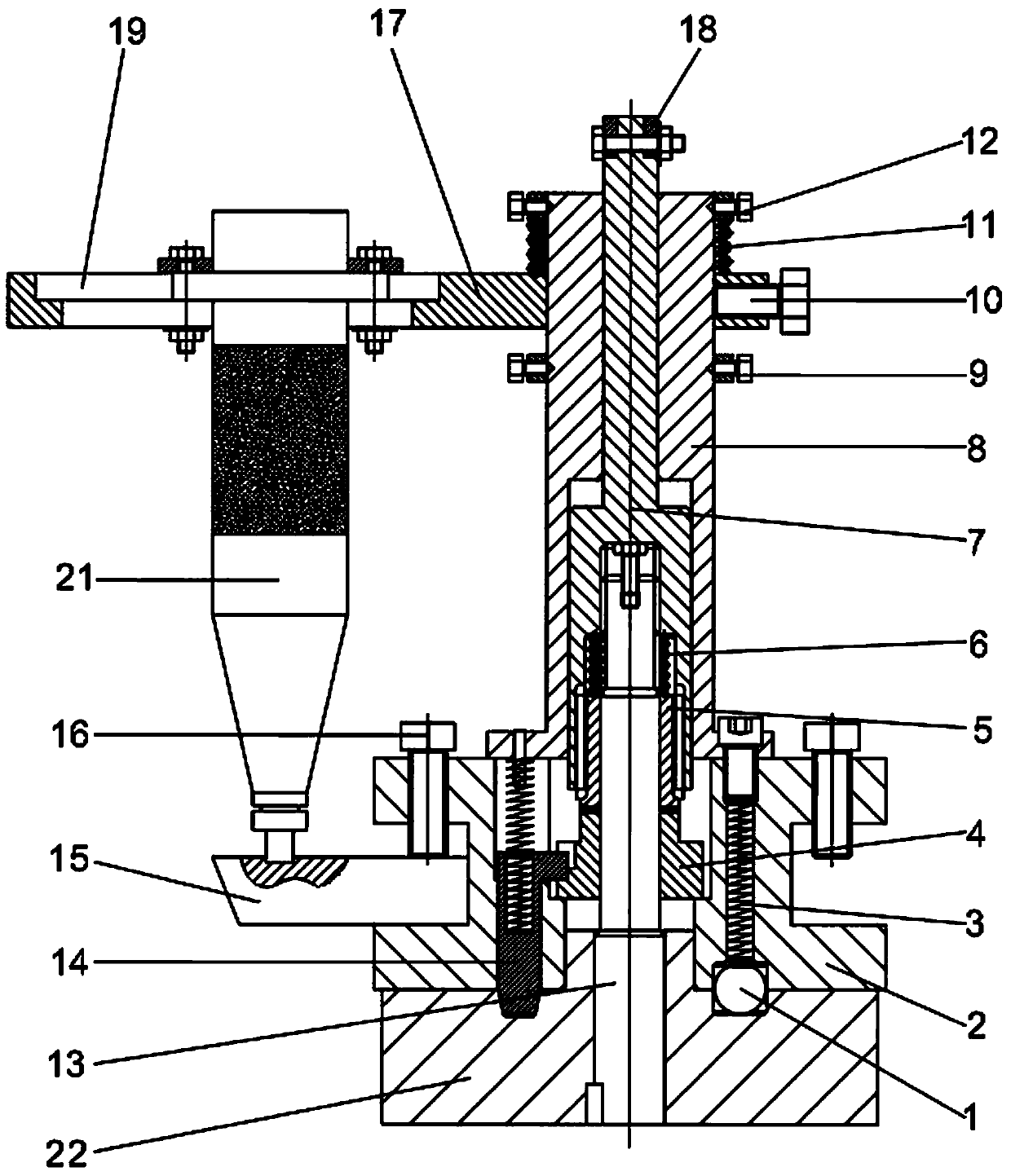

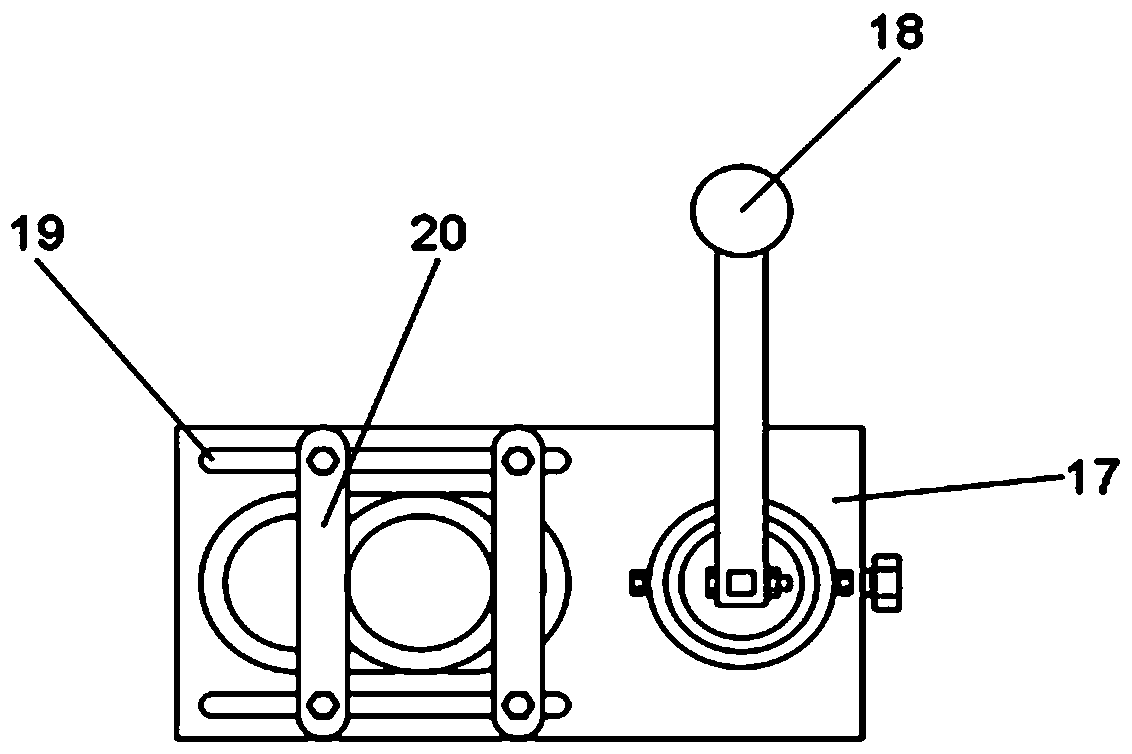

[0025] A multiple-frequency ultrasonic assisted turning device, comprising a main support frame, a turning tool 15 with a groove on the upper surface is installed horizontally on the main support frame, and a horizontal position and a vertical position can be adjusted vertically on the upper part of the main support frame. The multiple-frequency ultrasonic processing device 21 that can rotate around the main support frame, a spring compression device is installed between the multiple-frequency ultrasonic processing device 21 and the main support frame; The dimples are in contact and pressed tightly.

[0026] The portion of the lower end of the multiple-frequency ultrasonic machining device 21 in contact with the turning tool is circular, square or triangular.

[0027] The upper part of the main support frame is covered with a support that can be adjusted up and down along the main support frame and rotates around the main support frame. The multiple frequency ultrasonic proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com