Oil-water separation tank

A technology of oil-water separation and pool wall, which is applied in the direction of liquid separation, separation method, grease/oily substance/floating matter removal device, etc. It can solve the problem that the oil collection pipe cannot smoothly remove grease, etc., and achieve good strength, smooth removal, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

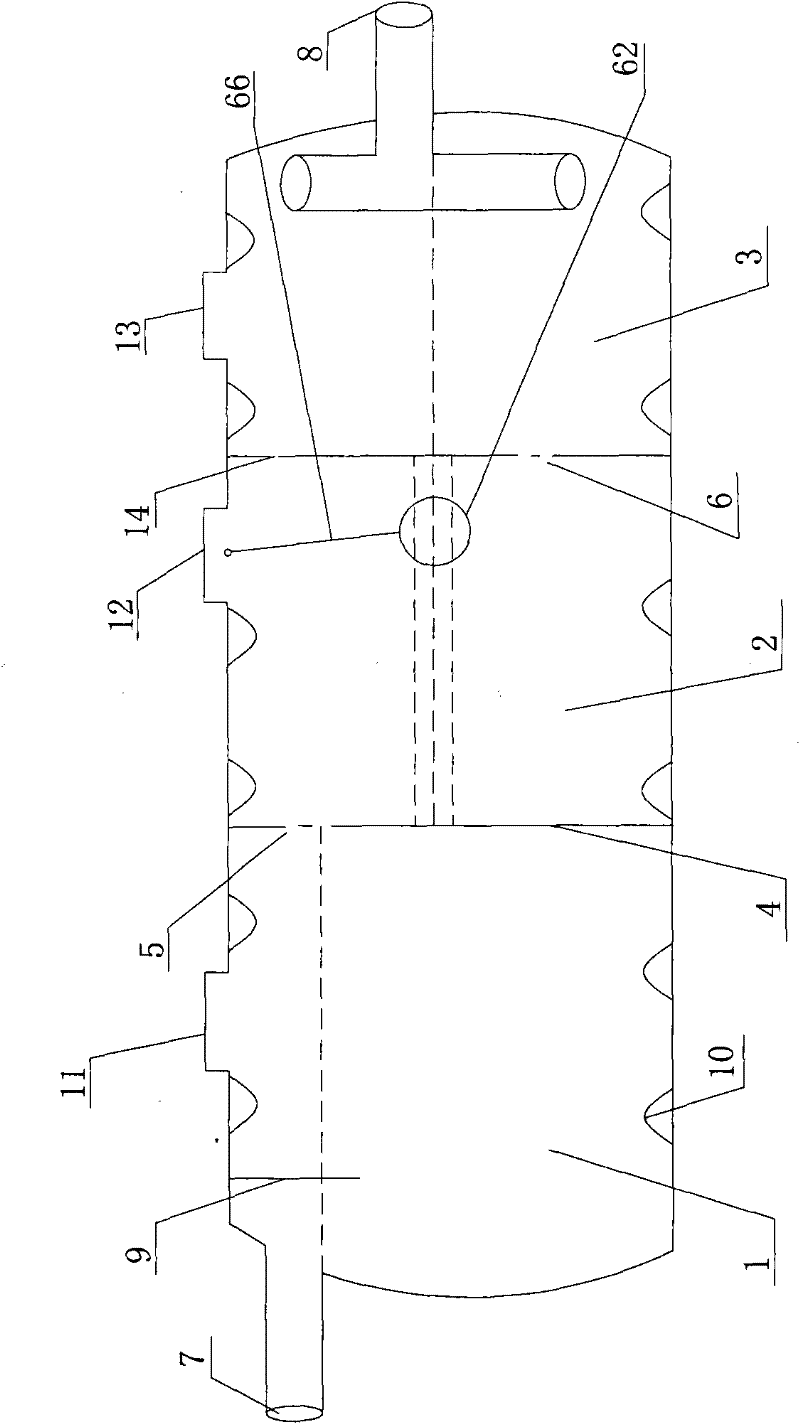

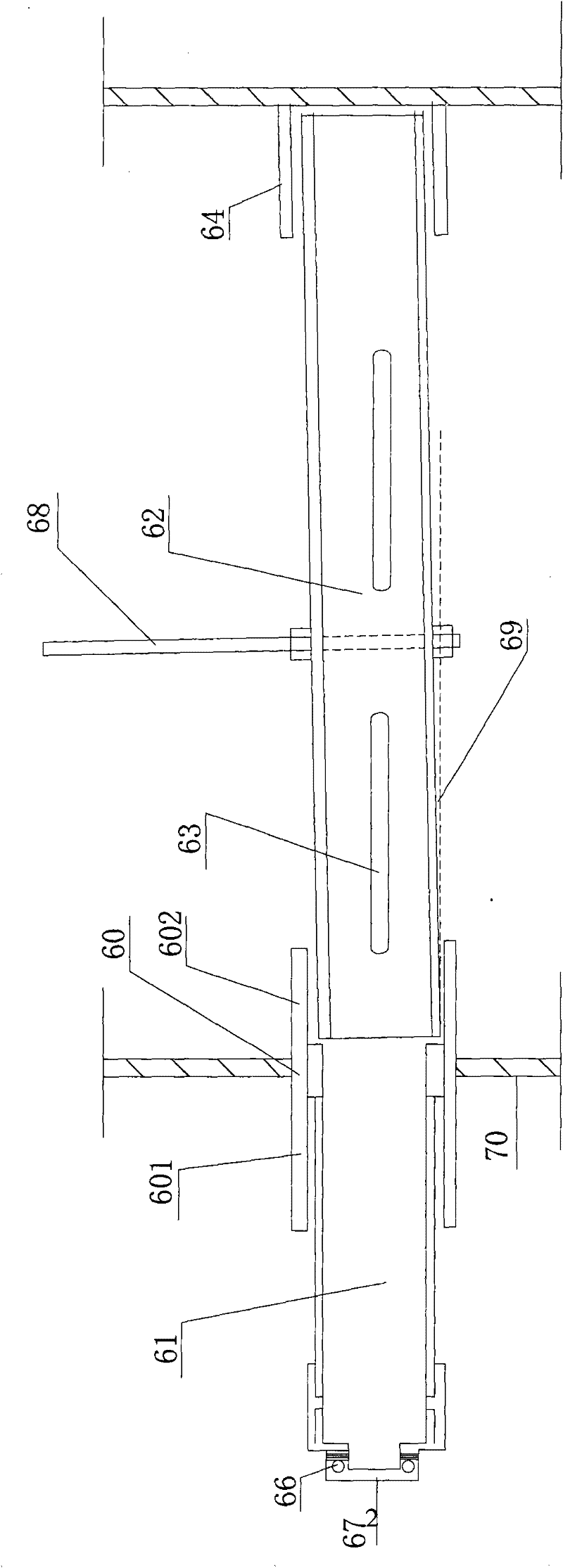

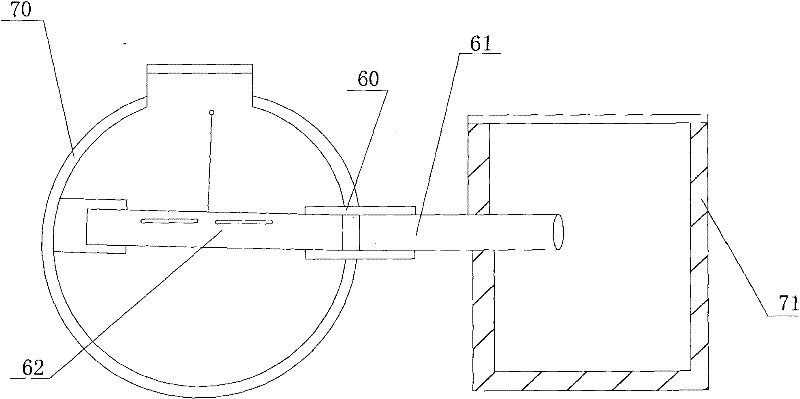

[0023] figure 1 , figure 2 and image 3 A specific embodiment of the oil-water separation tank of the present invention is given. The oil-water separation tank of the present invention is a sealed cylindrical overall structure, which includes a water inlet 7 separated by a partition 4. The water inlet chamber 1, the oil-water separation chamber 2 and the water outlet chamber 3 provided with a water outlet 8, the oil-water separation tank 2 are provided with rotating oil collecting pipes 62 installed obliquely on both sides of the pool body through mounting parts, and after the oblique installation The range of the tangent value of the angle 69 formed by the rotating oil collecting pipe and the horizontal direction is 0.5%-5%, and the preferred value is 1%. An operating rod 68 and two An oil inlet 63, when the rotating oil collecting pipe 62 rotates to the oil discharge state, the oil inlet 63 is parallel to the grease layer and is on the same level as the grease layer. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com