Thermal insulation board coating layer

An insulation board and coating technology, applied in anti-corrosion coatings and other directions, can solve the problems of unavoidable cold and hot bridges, difficult construction, construction difficulties, etc., and achieve the benefits of structural design, enhanced thermal insulation effect, and resistance to sudden changes in ambient temperature differences. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

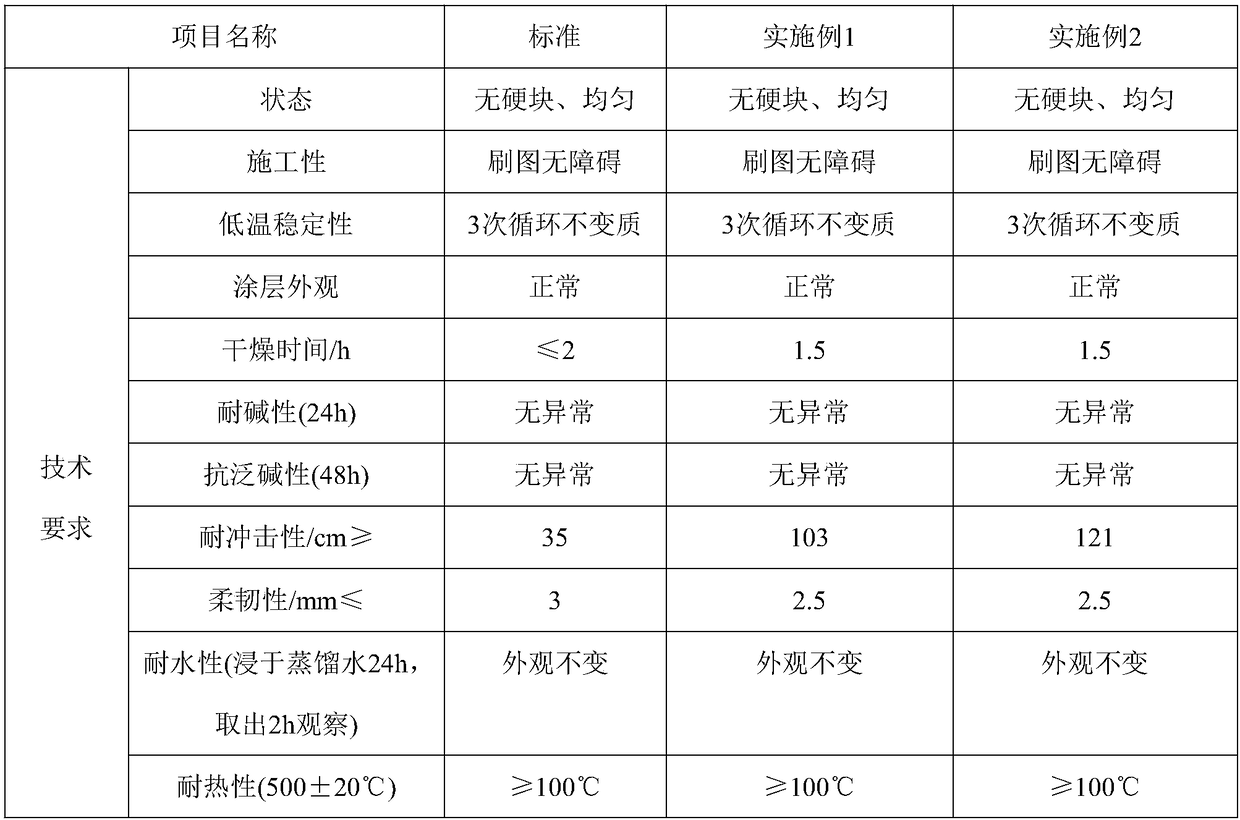

Embodiment 1

[0031] A kind of thermal insulation board coating comprises the raw material of following parts:

[0032] 12 parts of rigid polyurethane foam, 15 parts of ultra-low density polyethylene, 10 parts of trichlorethylene, 5 parts of carboxymethyl chitosan, 11 parts of 3,4-dimethylpyrazolate, 15 parts of sodium aluminate, 10 parts of polyglycerol fatty acid ester, 12 parts of dicyclohexylcarbodiimide, 6 parts of 4-dimethylaminopyridine, 8 parts of p-toluenesulfonic acid, 15 parts of terpene resin, 8 parts of ammonium polyphosphate, triphosphate 7 parts of phenyl ester, 12 parts of polyamide modified phenolic epoxy resin, 13 parts of graphite milk, 23 parts of polytetrafluoroethylene, 5 parts of organic bismuth antioxidant, 12 parts of copper oxide powder, 3 parts of concentrated hydrochloric acid, 5 parts of silane , 4.5 parts of antioxidant additives, 11 parts of propylene pitch resin, 10 parts of alkaline solution, 6 parts of deionized water, and 5 parts of ethanol.

[0033] In t...

Embodiment 2

[0053] A kind of thermal insulation board coating comprises the raw material of following parts:

[0054] 16 parts of rigid polyurethane foam, 12 parts of ultra-low density polyethylene, 8 parts of trichlorethylene, 11 parts of carboxymethyl chitosan, 10 parts of 3,4-dimethylpyrazolate, 17 parts of sodium aluminate, 6 parts of polyglycerol fatty acid ester, 13 parts of dicyclohexylcarbodiimide, 14 parts of 4-dimethylaminopyridine, 11 parts of p-toluenesulfonic acid, 13 parts of terpene resin, 7 parts of ammonium polyphosphate, triphosphate 8 parts of phenyl ester, 10 parts of polyamide modified phenolic epoxy resin, 12 parts of graphite milk, 23 parts of polytetrafluoroethylene, 12 parts of organic bismuth antioxidant, 20 parts of copper oxide powder, 12 parts of concentrated hydrochloric acid, 10 parts of silane , 4 parts of antioxidant additives, 6 parts of propylene pitch resin, 11 parts of alkaline solution, 8 parts of deionized water, and 5 parts of ethanol.

[0055] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com