Cement fiber hollow strip board, full cast-in-place formwork removal free building structure and construction method thereof

A technology of cement fiber and hollow slats, which is applied to building components, building structures, buildings, etc., can solve the problems of cumbersome construction, low construction efficiency, and a lot of construction waste, and achieve the advantages of easy installation and layout, simple construction methods, and structural high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

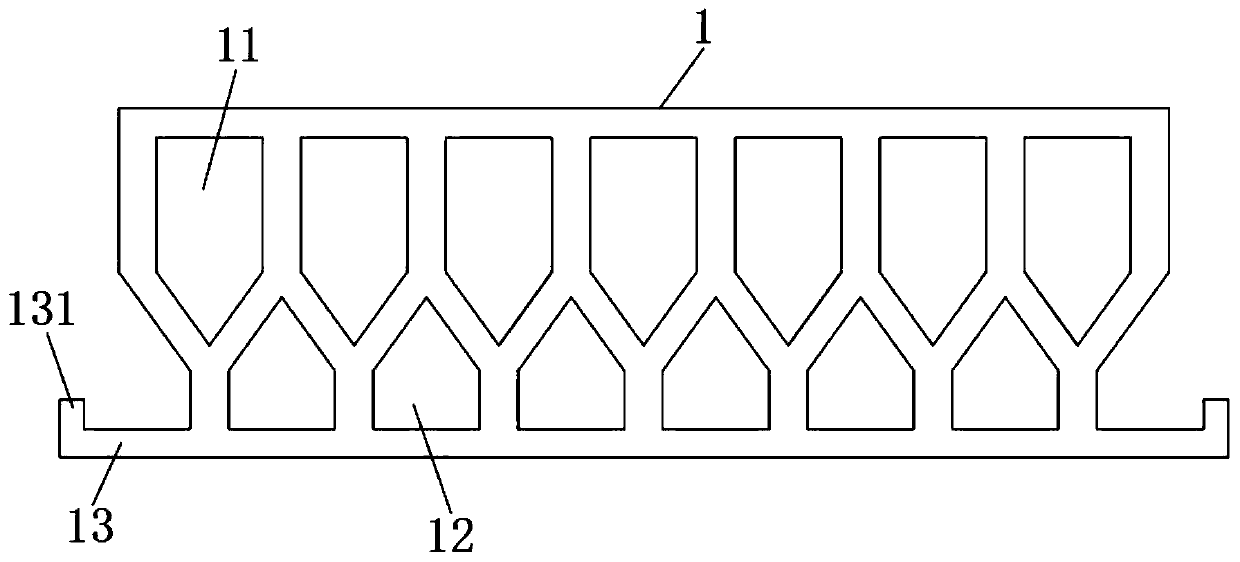

[0046] Embodiment one: if figure 1 As shown, the cement fiber hollow slats of this embodiment include a strip-shaped plate body 1 arranged horizontally. The above-mentioned plate body 1 is a cement fiber board. The inside is respectively provided with a plurality of upper wiring holes 11 and a plurality of lower wiring holes 12 passing through it along its length direction. The holes 12 are arranged in a row at the lower part inside the board body 1 , and the lower ends of the two sides of the board body 1 are respectively integrally formed and horizontally provided with splicing parts 13 extending outward on both sides.

[0047] The above board body 1 is extruded by a screw extruder and installed on site after manufacture in the factory. The width is generally 400mm and the thickness is 100mm. The strip board can replace the building formwork during construction, which is convenient for construction, saves costs, and can reduce construction costs. In addition, the slats are ...

Embodiment 2

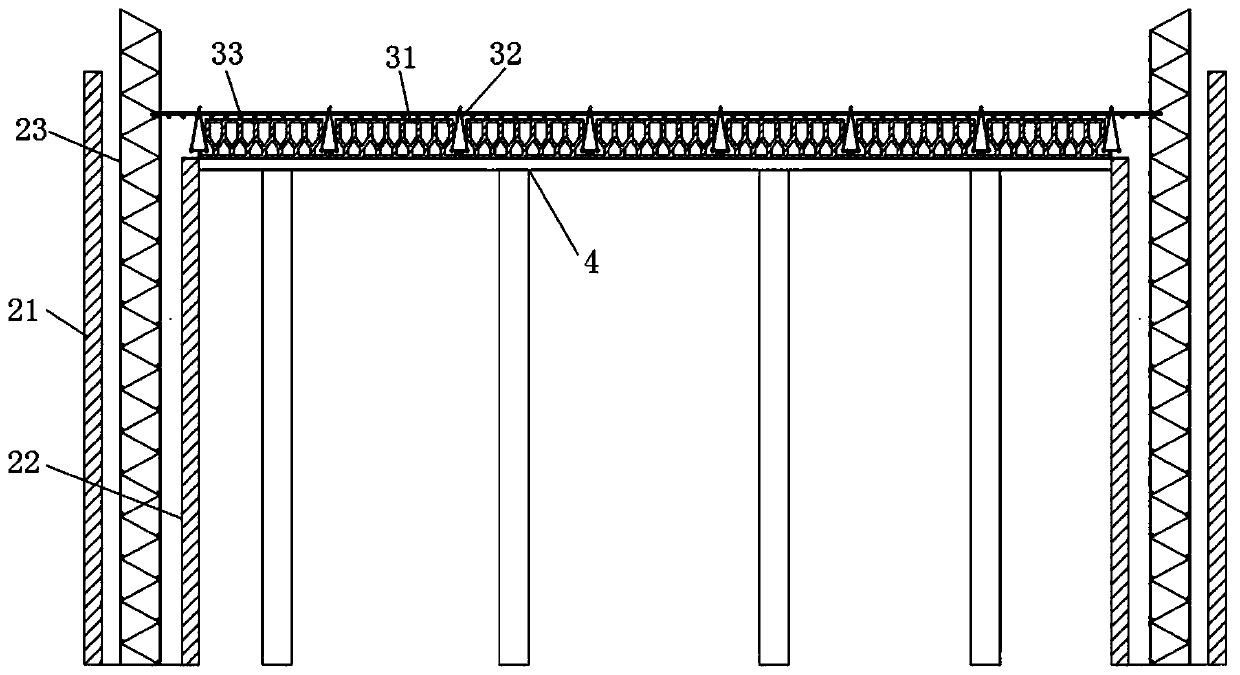

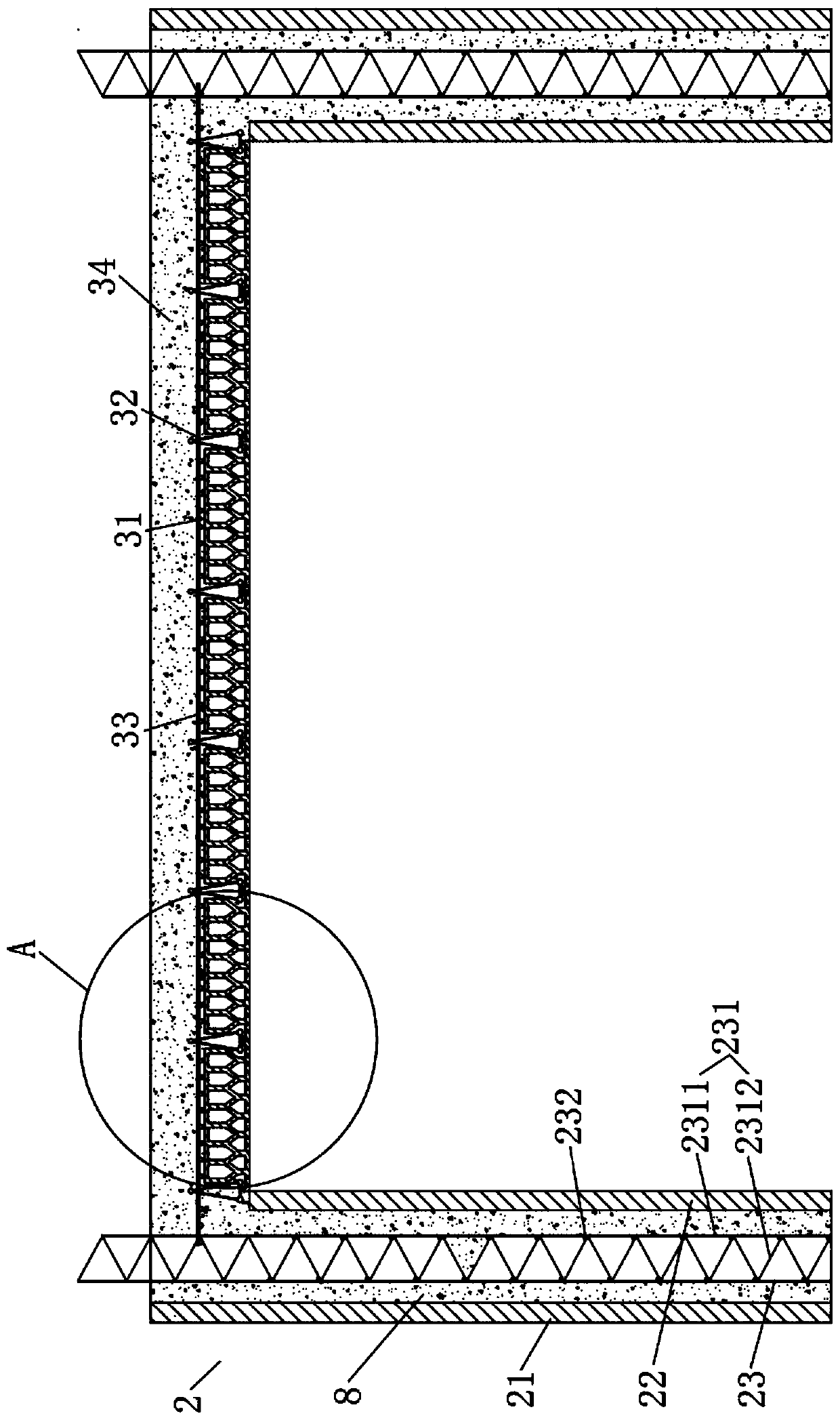

[0050] Embodiment two: if figure 2 and 3 As shown, a kind of all-in-place cast-in-place free formwork building structure comprises wall body 2 and floor structure 3; above-mentioned floor structure 3 comprises cement fiber hollow strip 31, triangular steel bar truss 32, steel mesh sheet as embodiment one 33 and a concrete layer 34; the above-mentioned cement fiber hollow slats 31 are provided with multiple strips, and are distributed horizontally and side by side respectively. , and the above-mentioned splicing parts 13 of two adjacent cement fiber hollow slats 31 on one side abut against each other; the above-mentioned triangular steel bar truss 32 is strip-shaped, and is provided with multiple, and respectively along the above-mentioned cement fiber hollow slats The length direction of 31 is arranged between two adjacent above-mentioned cement fiber hollow slats 31, and the two main bars of the above-mentioned triangular steel truss 32 are respectively located above the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com