Microphone automated welding device and method

An automatic welding and microphone technology, applied in auxiliary devices, welding equipment, soldering irons, etc., can solve problems such as poor flexibility and scalability, inability to achieve high-quality welding of microphones, and inability to adjust the movement position according to materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

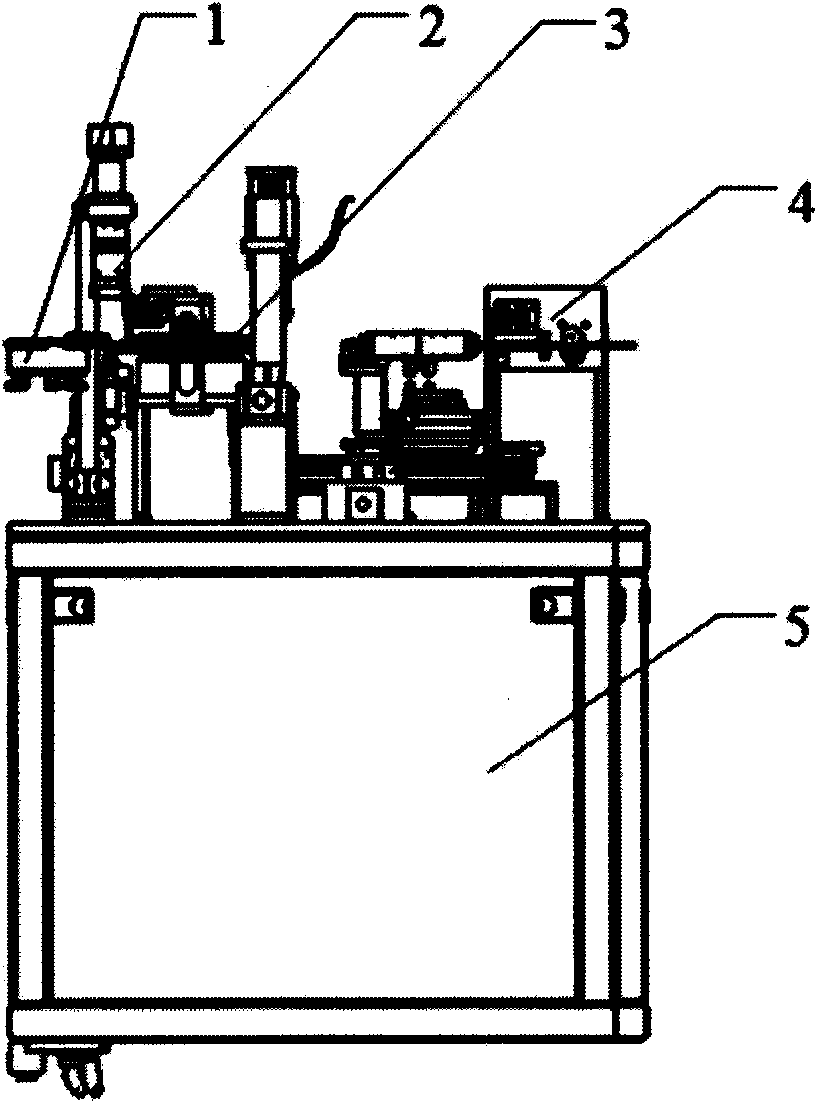

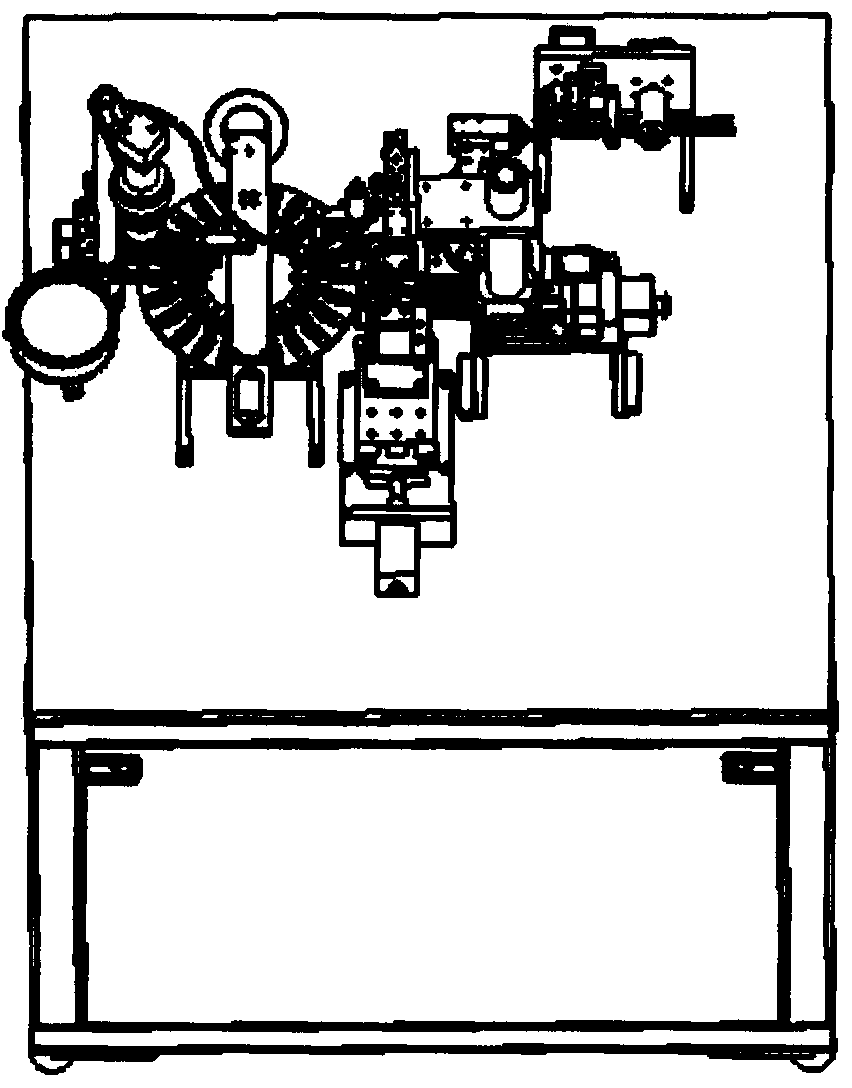

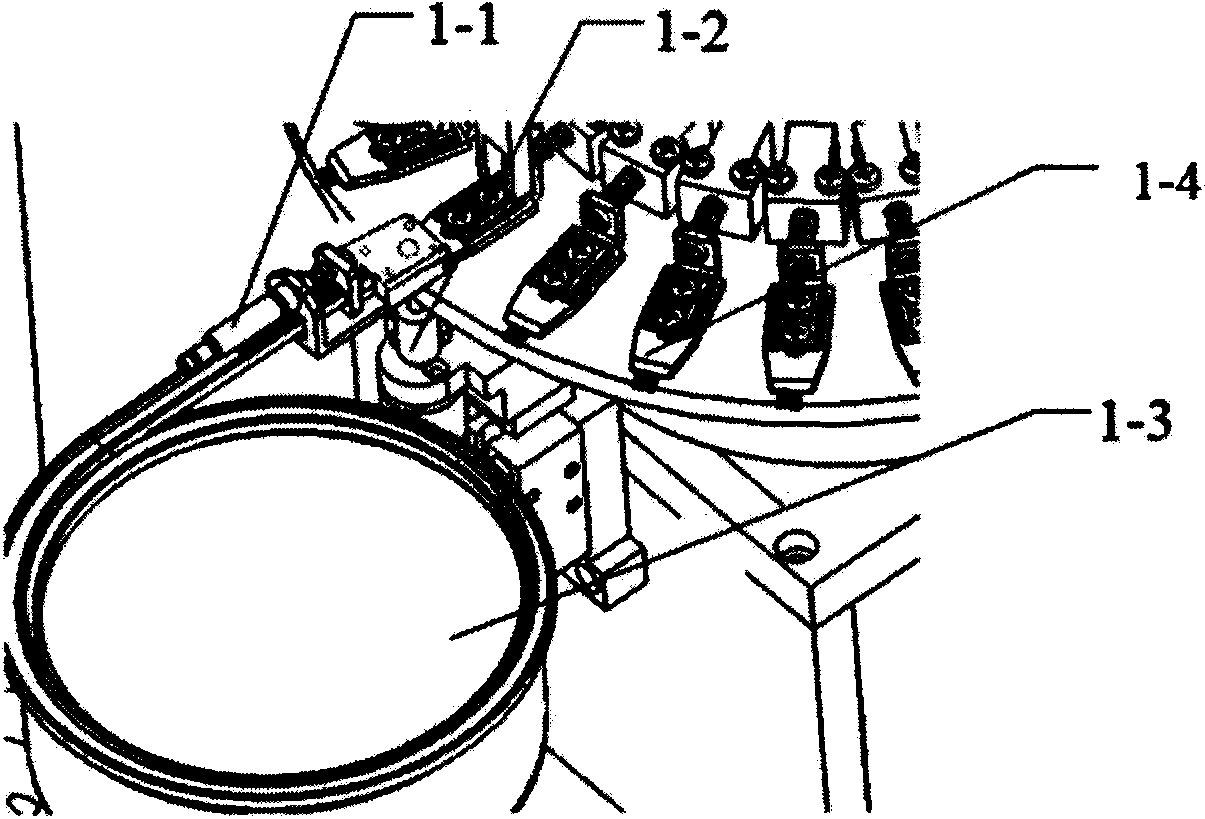

[0031] Among the figure, a kind of Microphone microphone automatic welding device comprises vibrating plate feeding module 1, image acquisition module 2, soldering operation module 3, lead wire feeding module 4 and electric control cabinet 5, it is characterized in that, described vibrating plate feeding module 1 Including pneumatic feeding mechanism 1-1, electric microphone head pad adjustment mechanism 1-2, screenable vibrating plate 1-3, microphone head clamping block mechanism 1-4, microphone head unloading cylinder mechanism 1-5, microphone head Feeding cylinder mechanism 1-6, spring return block 1-7, electric rotary operation platform 1-8, wherein, the microphone heads are all selected as facing up by the vibrating plate, and the microphone head feeding cylinder mechanism 1- 6 Actions to loosen the microphone head clamping block mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com