LED lamp pin welding method and equipment

A technology of LED lights and welding equipment, which is applied in welding equipment, metal processing equipment, lighting and heating equipment, etc., and can solve problems such as not being able to meet the demand of the LED market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

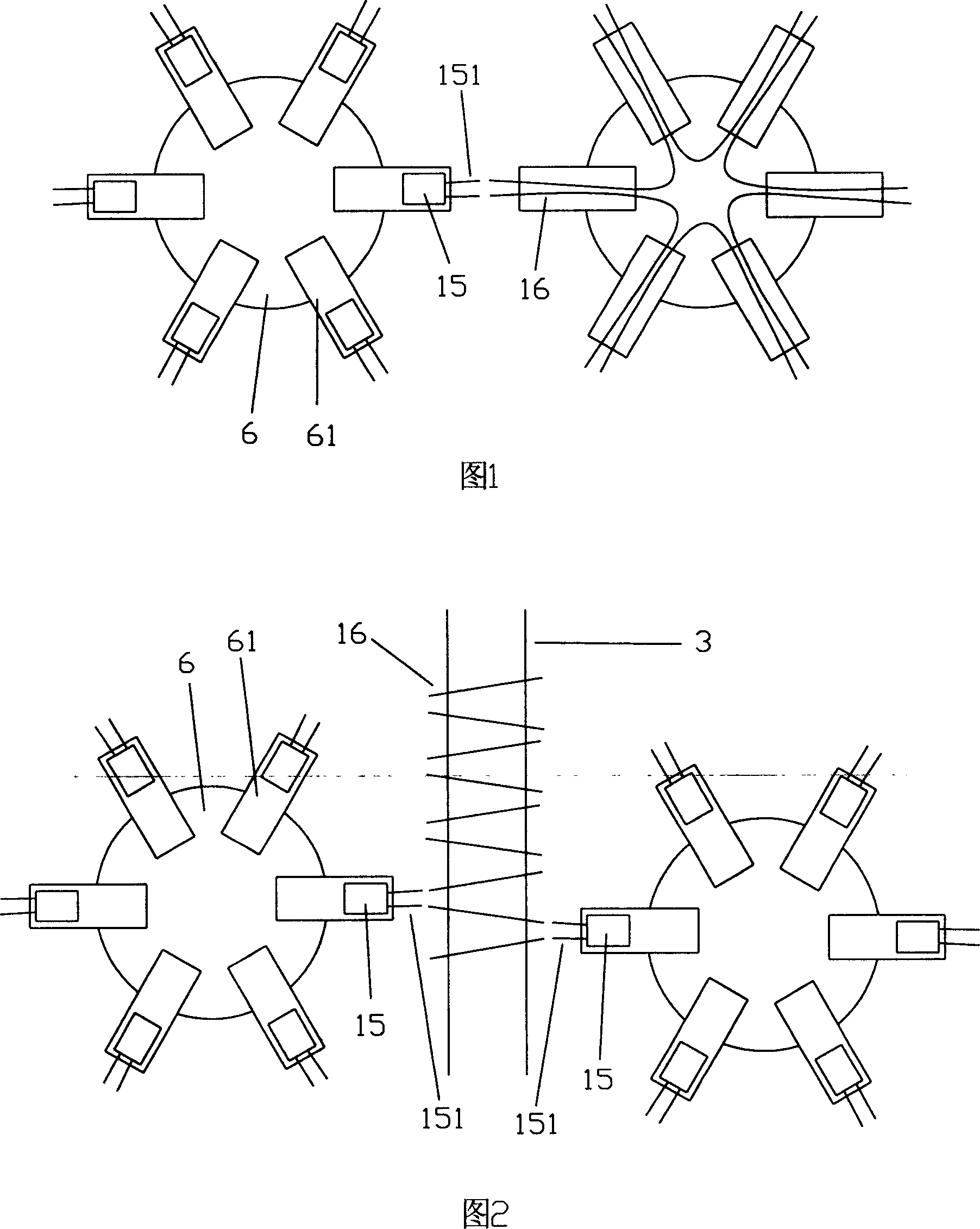

[0011] The difference between the existing welding process equipment and the present invention will be briefly described below. As shown in Figure 1 is a brief schematic diagram of the existing welding process equipment. The pretreated LED15 and wire 16 are placed on two adjacent disc-shaped clamping devices 6 respectively, the two lamp pins 151 of the LED15 are placed outwards, and the wire 16 is placed on both sides of the clamping device 6 in an arc shape. On the first clamping block 61, when the unwelded LED15 and the wire 16 were in the alignment position at the same time, the welding device welded, so that the two lamp pins 151 of the LED15 were welded to the two wires 16 respectively, and two solder joints were completed at a time.

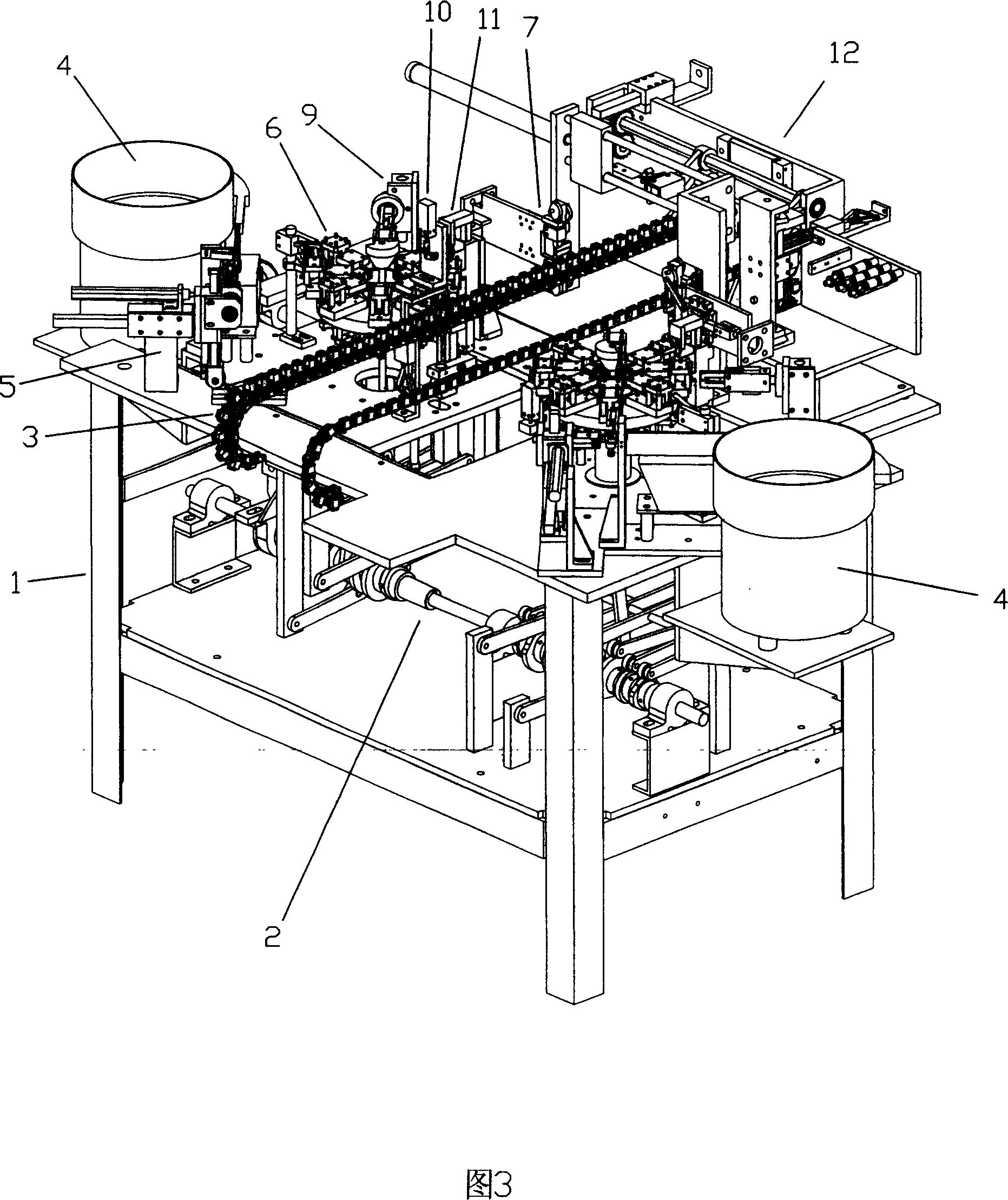

[0012] As shown in Figure 2 is a schematic diagram of the process equipment of the present invention. The pretreated LED15 is placed on two disc-shaped clamping devices 6, while the pretreated wire 16 is placed on the side-by-side conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com