Multidirectional rotation working soldering tin machine capable of overturning jigs

A multi-directional, soldering machine technology, applied in manufacturing tools, metal processing, welding equipment, etc., can solve problems such as inconvenient operation, long soldering interval time, and large soldering limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

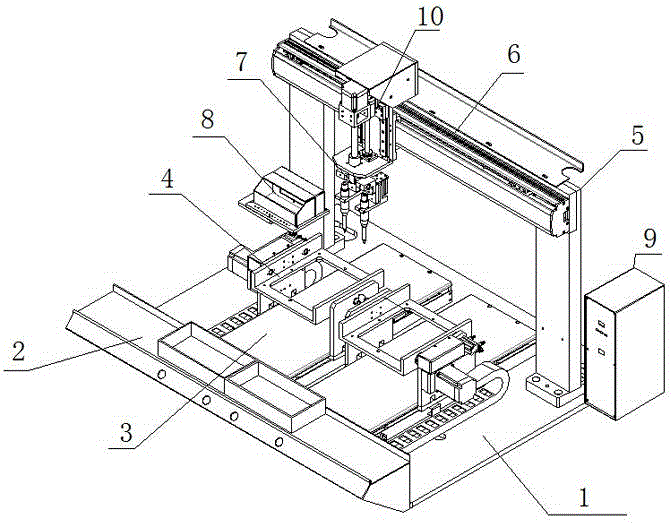

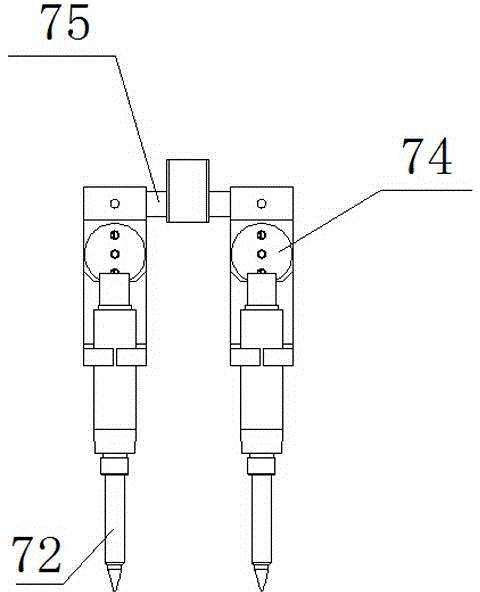

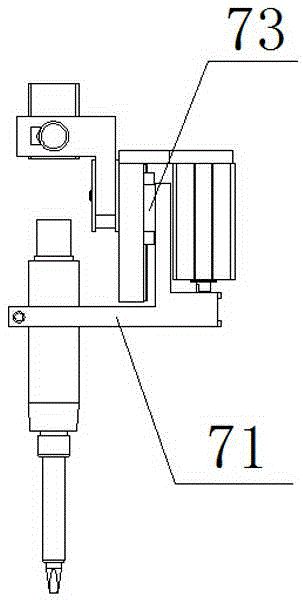

[0013] In this example, if Figure 1 to Figure 4 As shown, a reversible fixture multi-direction rotation work soldering machine of the present invention includes a machine panel 1, a material table 2 arranged in front of the machine panel 1, and a Y-axis transmission mechanism longitudinally arranged on the upper surface of the material table 2 3, and the turning mechanism 4 set on the Y-axis transmission mechanism 3 by sliding back and forth, and the welding bracket 5 set above the material table 2, and the X-axis transmission mechanism 6 set on the top of the welding bracket 5, and the X-axis transmission mechanism set on the X-axis In front of the mechanism 6, a multi-head independent control welding mechanism 7 that can slide left and right, and a tin slag box 8 that is arranged on the left end of the welding bracket 5 and is used to recycle the soldering iron by blowing tin or carry out tin cleaning treatment on the tip of the soldering iron, and is arranged on the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com