Method for producing coating drier through module control

A technology of module control and drier, applied in driers, chemical instruments and methods, etc., can solve the problems of poor physical and mental health of workers, unstable product quality, large product differences, etc., to achieve good health and reduce labor. Strength, guaranteed clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

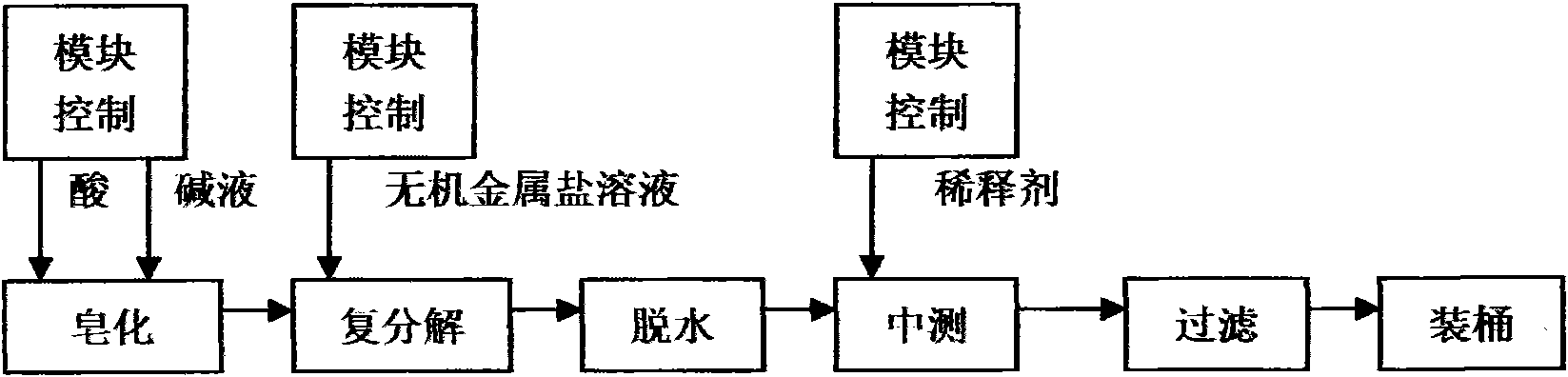

Image

Examples

Embodiment 1

[0030] (1) Saponification reaction

[0031] The reaction raw materials isooctanoic acid, 80% by weight of sodium hydroxide solution, 50% by weight of calcium chloride solution and No. 200 solvent oil are pumped into respective high-level tanks respectively, and are set by Mettler-Toledo weighing display controller. A fixed module, 1450 kilograms of isooctanoic acid, 500 kilograms of 80% by weight of sodium hydroxide solution are added in the reactor, heated to 90 ° C, saponification reaction is carried out under stirring, and the reaction time is half an hour;

[0032] (2) metathesis reaction

[0033] Through the module set by the Mettler-Toledo weighing display controller, add 1110 kilograms of 50% by weight calcium chloride solution into the reaction kettle of step (1), and carry out the metathesis reaction under stirring, and the reaction temperature is 80-120°C , the reaction time is 0.5 to 0.6 hours, the reaction solution is allowed to stand for stratification and dehydr...

Embodiment 2

[0035] In addition to adding 1610 kilograms of 50% by weight zinc sulfate to the reaction kettle of step (1) in step (2) and carrying out metathesis reaction, adding 1075 kilograms of solvent oil No. 200 to the above-mentioned reaction kettle to dilute the reaction solution, all the other raw materials are composed and reaction steps All the same as in Example 1, the result was 2840 kg of light yellow transparent liquid drier product, the zinc content of the product was 17% by weight, and the product yield was 80%.

Embodiment 3

[0037] In addition to adding 2780 kilograms of 50% by weight lead chloride to the reactor of step (1) in step (2) and carrying out metathesis reaction, adding 840 kilograms of No. 200 solvent oils to dilute the reaction solution in the above reactor, the composition and reaction of all the other raw materials The steps are the same as in Example 1, and as a result, 3315 kg of orange transparent liquid drier product is obtained, the lead content of the product is 31% by weight, and the product yield is 85%.

[0038] The Mettler-Toledo weighing display controller in Examples 1-3 is produced by Mettler-Toledo (Changzhou) Weighing Equipment Co., Ltd., and the model is XK3123.

[0039] The yields of Examples 1 and 2 are 3% higher than the prior art, and the yields of Example 3 are 5% higher than the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com