Bee toxicology experiment contamination automatic feeding device and application thereof

A feeder and bee technology, applied in applications, beekeeping, animal husbandry, etc., can solve problems affecting accuracy, waste of raw materials, honey dripping, etc., and achieve the effect of simple structure and accurate feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

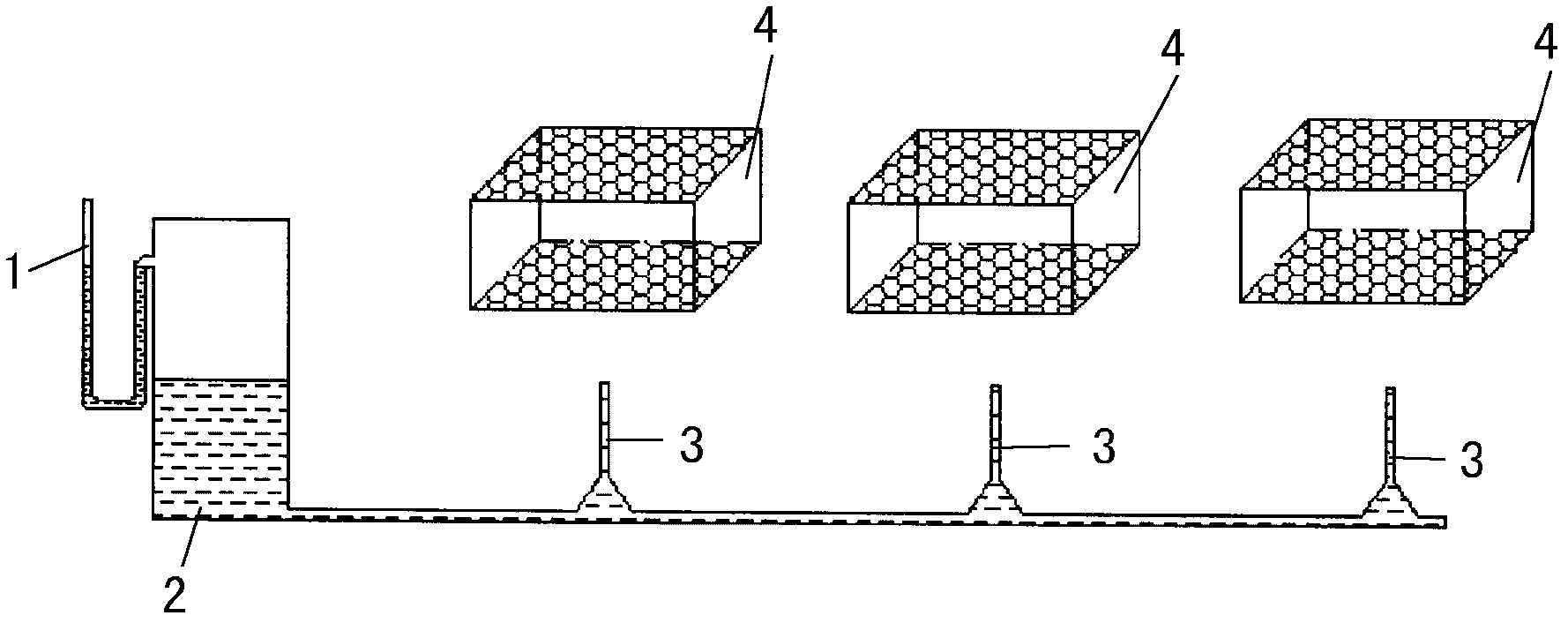

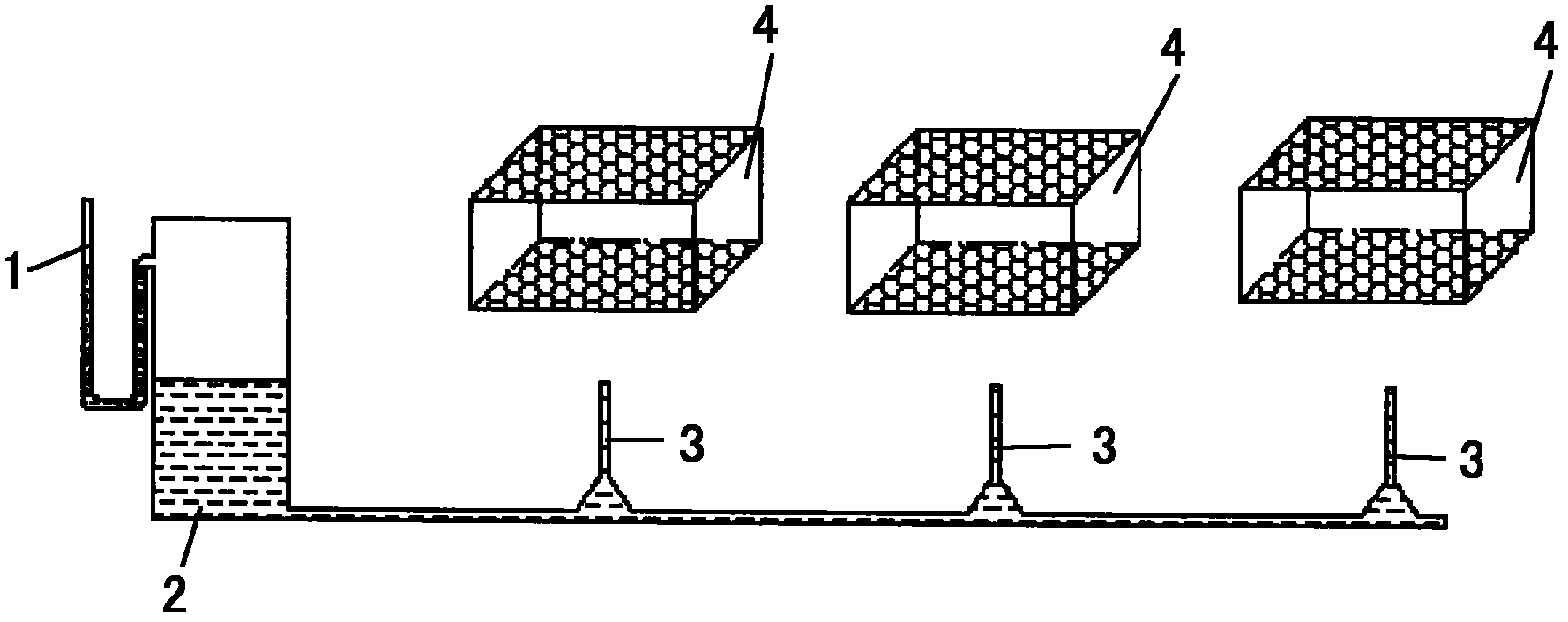

[0027] see figure 1 , the present invention comprises a U-shaped tube 1, a liquid reservoir 2, a feeder 3 and a bee box 4, such as figure 1 shown. Among them, the bee box 4 except the upper and lower sides, the four sides are wooden box walls, the size is 10.5cm*10.0cm*8.0cm, the thickness of the box wall is 1cm, 20 bees are placed in each box, and the upper and lower sides of the box wall are used The gauze was tightly sealed to prevent the bees from escaping during the experiment.

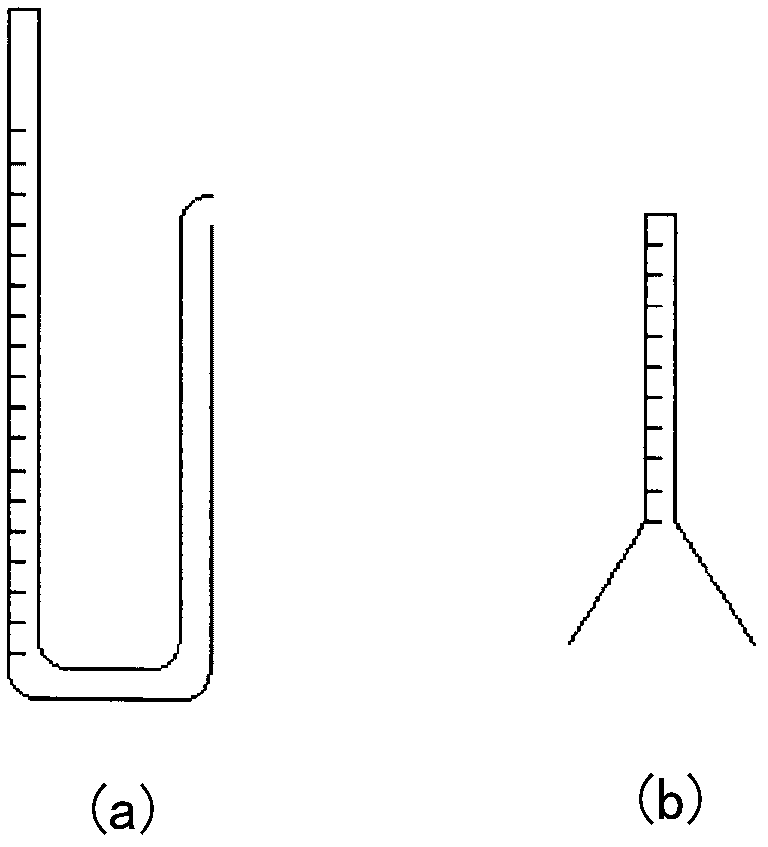

[0028] Its specific structure is: one side port of the U-shaped tube 1 is directly connected to the liquid reservoir 2 (according to the direction shown in the figure, it refers to the right side port of the U-shaped tube, which is referred to as the right side for convenience in the following description), The port on the other side of the U-shaped tube 1 that is not connected to the liquid reservoir 2 (according to the direction shown in the figure, refers to the left port of the U-shaped tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com