Intelligent pet feeder

A technology for feeders and pets, applied in the field of feeders, can solve the problems of stuck food, poor practicability, large shell volume, etc., and achieve the effects of increasing the food filling capacity, precise feeding amount, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

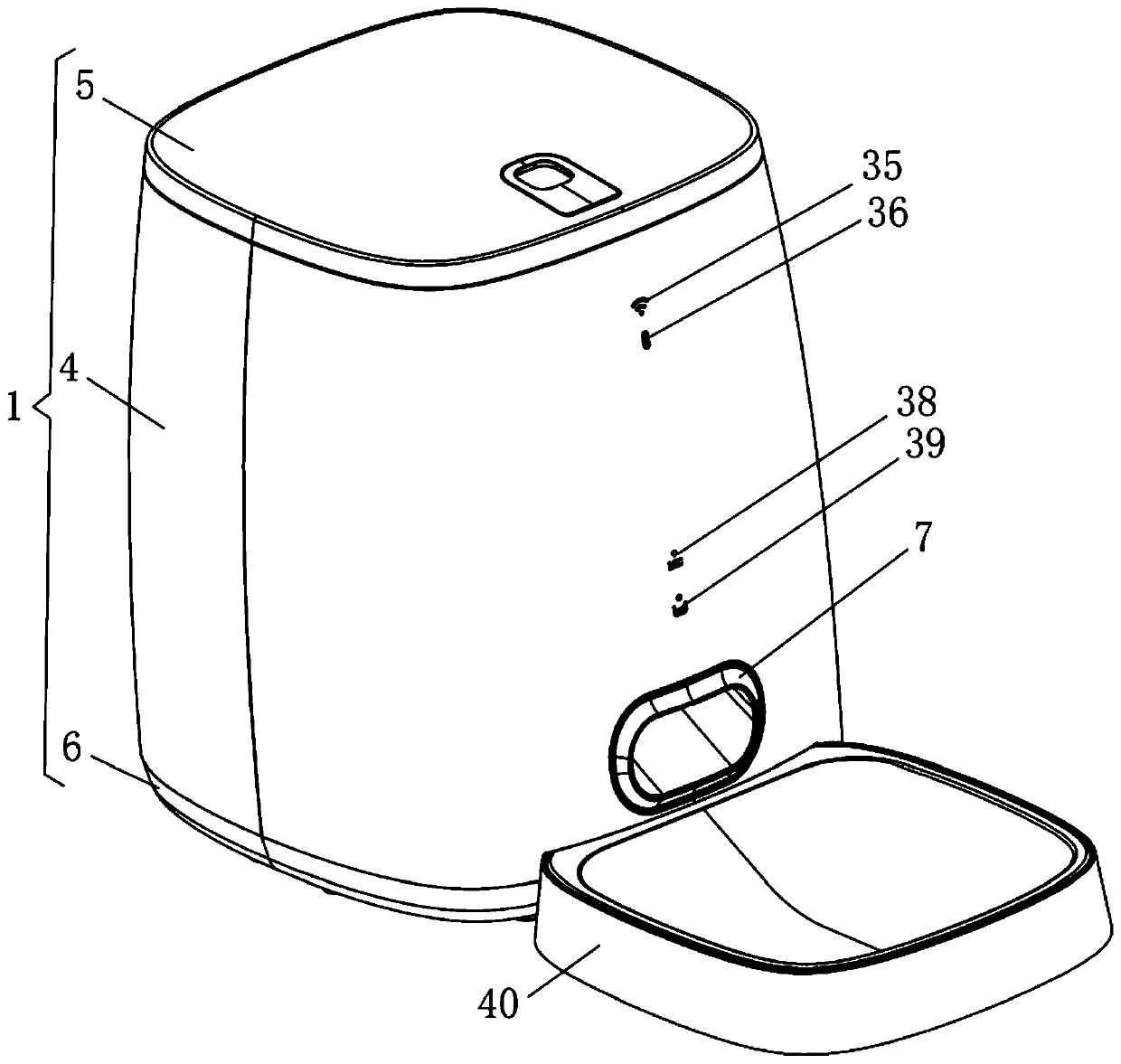

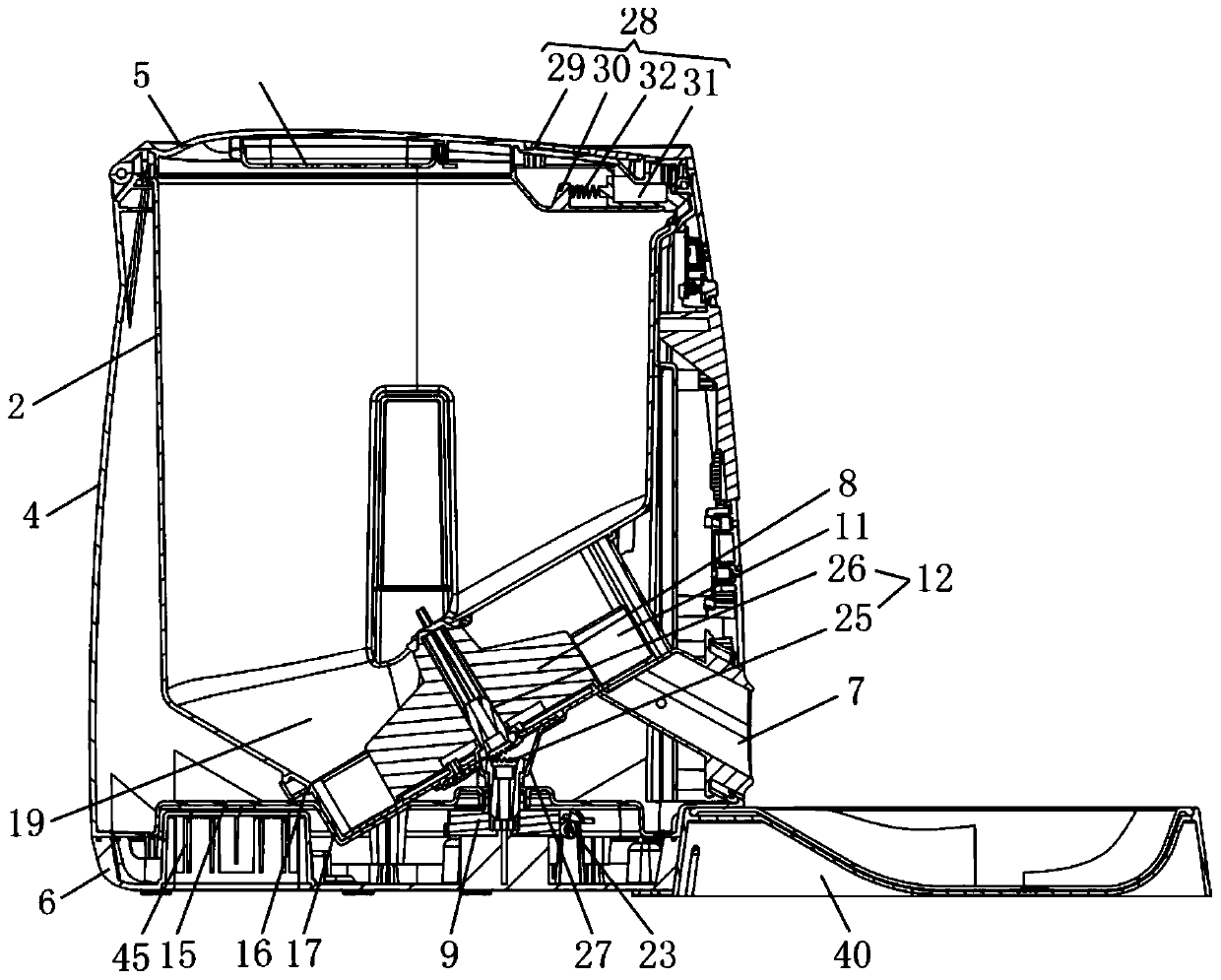

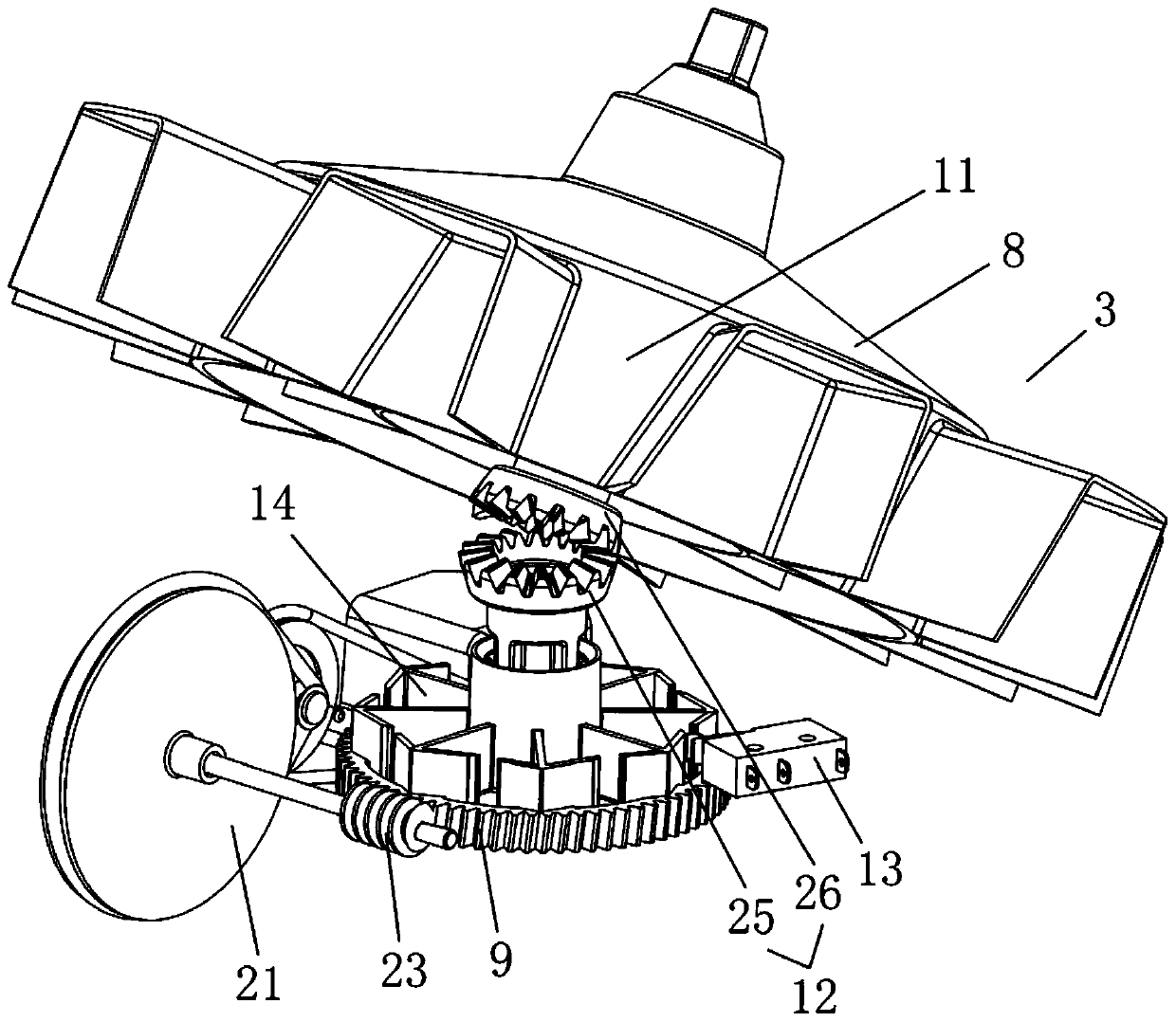

[0028] Such as Figure 1-11 As shown, a smart pet feeder includes a casing 1, a bucket 2 and a feeding device 3, and the casing 1 includes an outer barrel body 4 and a barrel cover 5 and a bottom shell respectively arranged at both ends of the outer barrel body 4 6. The outer barrel body 4 is provided with a discharge channel 7, the material barrel 2 is installed in the outer barrel body 4, and the material pulling device 3 is installed between the material barrel 2 and the bottom shell 6 Between, the material shifting device 3 includes a material shifting rotor 8 and a control gear 9, a blocking piece 10 is arranged between the barrel 2 and the shifting material rotor 8, and the shifting material rotor 8 is rotatably and obliquely arranged on At the bottom of the barrel 2, the shifting rotor 9 is provided with several storage tanks 11 distributed alternately, the control gear 10 is connected to the shifting rotor 9 through a bevel gear mechanism 12, and the control gear 10 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com