Cyanide-free copper-zinc alloy electroplating solution and preparation method thereof

An alloy electroplating solution and electroplating solution technology are applied in the field of electrochemical copper-zinc plating, which can solve the problems affecting the health of operators, polluting the environment, and difficult wastewater treatment, and achieve low production costs, low impurity content, and low wastewater treatment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of cyanide-free copper-zinc alloy electroplating solution, said preparation method comprising the following steps:

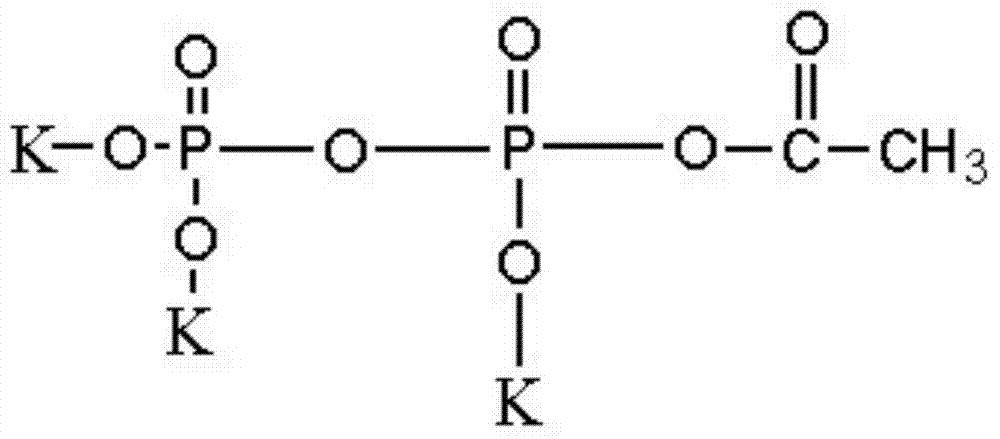

[0045] (1) Preparation of complexing agent: the general formula of the complexing agent is M x H y P n O 3n +1R z , Where x=3, y=0, n=2, z=1, M is K + , R is an acetyl group, the specific structural formula is as follows:

[0046]

[0047] Potassium hydroxide, phosphoric acid and acetic acid were mixed and reacted at a molar ratio of 3:2:1, and the reaction solution was spray-dried to obtain partially polymerized intermediate powder. The intermediate powder was placed in a rake dryer for polymerization at 250°C for 10 hours , The finished product of complexing agent is obtained after the polymerization reaction is finished;

[0048] (2) Preparation of copper salt: the complexing agent prepared in step (1) is mixed with copper sulfate at a molar ratio of 2:3 in an aqueous phase system and reacted at 25°C for 1 hour. After the reaction, it is ...

Embodiment 2

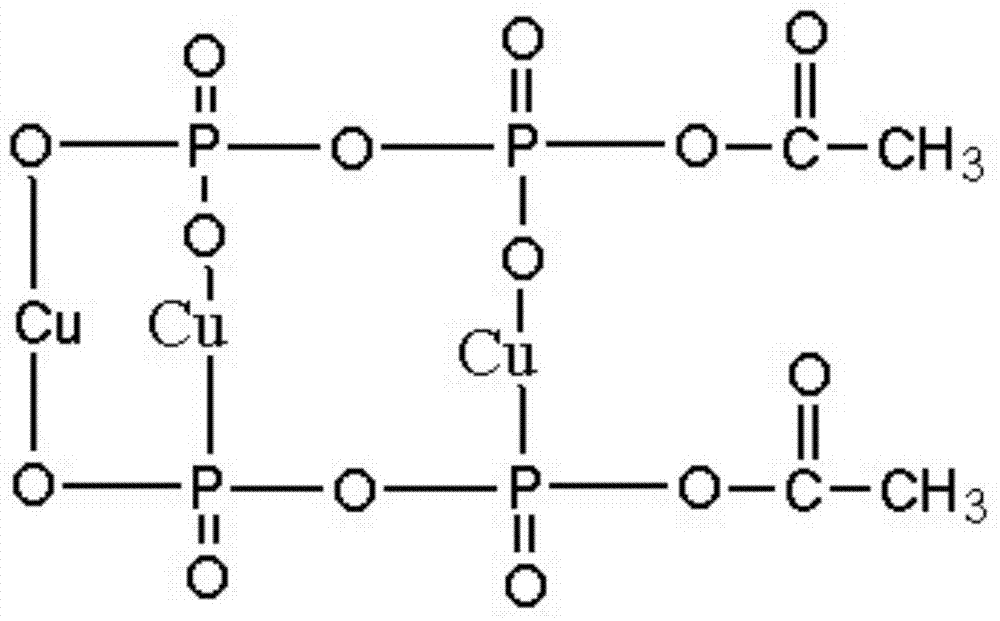

[0054] A preparation method of cyanide-free copper-zinc alloy electroplating solution, said preparation method comprising the following steps:

[0055] (1) Preparation of complexing agent: the general formula of the complexing agent is M x H y P n O 3n +1R z , Where x=3, y=0, n=3, z=2, M is K + And Na + , R is an acetyl group, the specific structural formula is as follows:

[0056]

[0057] Sodium hydroxide, phosphoric acid and acetic acid were mixed and reacted at a molar ratio of 3:3:2, and the reaction solution was flash dried to obtain a partially polymerized intermediate powder. The intermediate powder was placed in a rake dryer at 200°C for polymerization. 10h, after the polymerization reaction, the finished product of complexing agent is obtained;

[0058] (2) Preparation of copper salt: the complexing agent prepared in step (1) and copper sulfate at a molar ratio of 2:3 are mixed uniformly in an aqueous system, reacted at 100°C for 0.5h, and centrifuged and dried after the re...

Embodiment 3

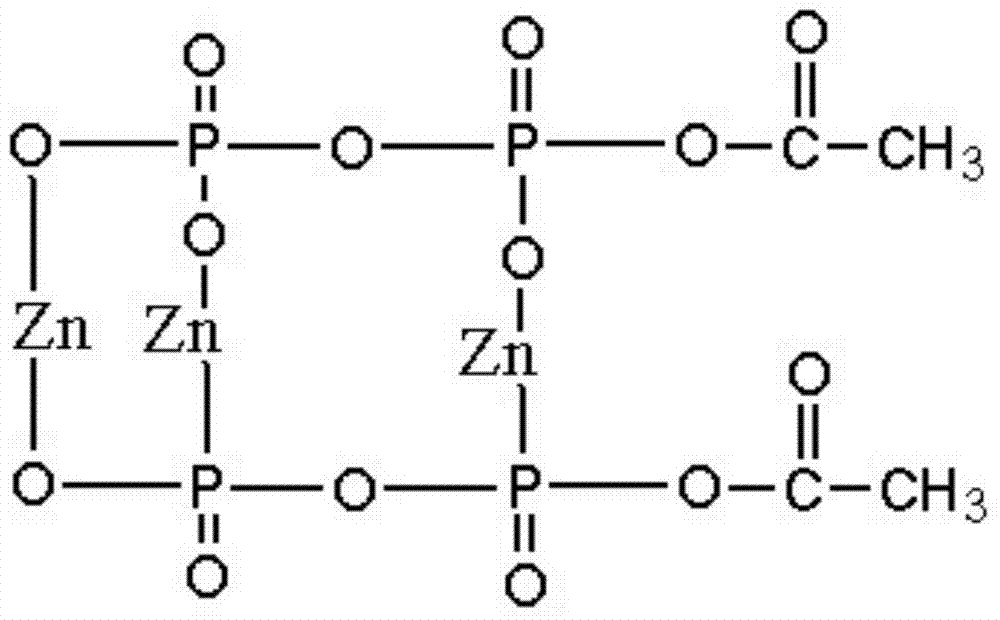

[0064] A preparation method of cyanide-free copper-zinc alloy electroplating solution, said preparation method comprising the following steps:

[0065] (1) Preparation of complexing agent: the general formula of the complexing agent is M x H y P n O 3n +1R z , Where x=1, y=100, n=100, z=1, M is Na + , R is an acetyl group, the specific structural formula is as follows:

[0066]

[0067] Sodium bicarbonate, phosphoric acid and acetic acid were mixed and reacted at a molar ratio of 1:100:1, and the reaction solution was flash dried to obtain partially polymerized intermediate powder. The intermediate powder was placed in a rake dryer at 300°C for polymerization. 2.5h, the finished product of complexing agent is obtained after the polymerization reaction is finished;

[0068] (2) Preparation of copper salt: Mix the complexing agent prepared in step (1) with copper sulfate at a molar ratio of 2:1, and react at 25°C for 1.0 h. After the reaction, the copper salt is obtained by centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com