Zinc wire feeding device

A feeding device and zinc wire technology, applied in the direction of inorganic chemistry, non-metallic elements, silicon compounds, etc., to achieve the effects of high equipment stability, low energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

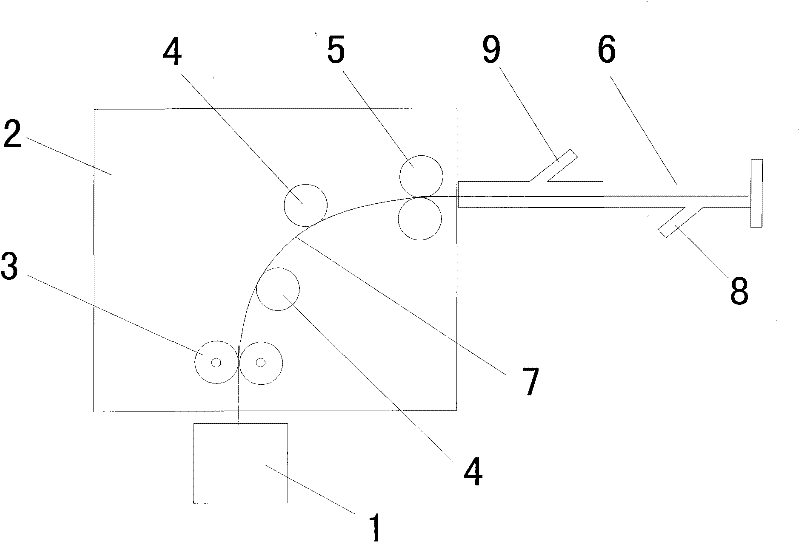

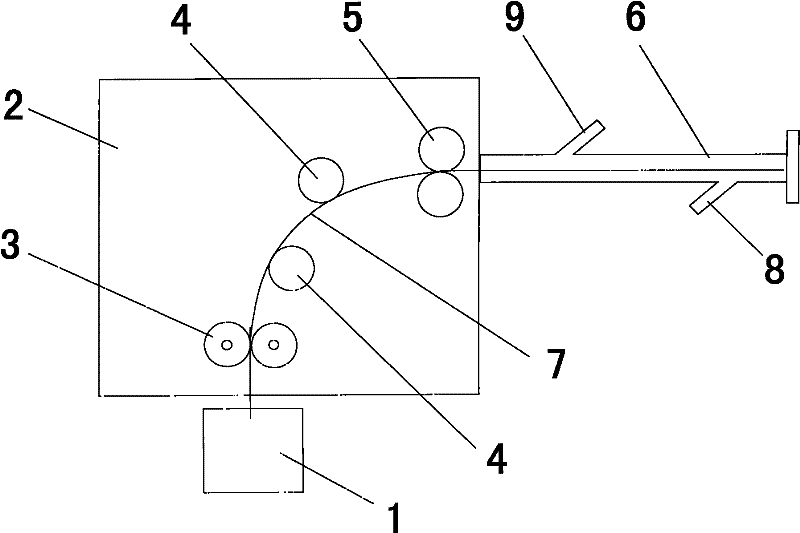

[0025] see figure 1 , the zinc wire feeding device of the present invention is sealed and connected with the polysilicon reactor produced by the zinc reduction method. It includes a zinc wire supply mechanism 1, a fixed panel 2, a wire feeding mechanism 3, a zinc wire guide wheel 4, a zinc wire directional wheel 5 and a zinc wire feeding sleeve 6. The zinc wire providing mechanism 1, the fixed panel 2 and the zinc wire feeding casing 6 are arranged in sequence according to the advancing route of the zinc wire 7. The wire feeding mechanism 3, the zinc wire guide wheel 4 and the zinc wire orientation wheel 5 are fixed on the fixed panel 2 in sequence according to the advancing path of the zinc wire 7. The zinc wire 7 drawn out by the zinc wire supply mechanism 1 passes through the wire feeding mechanism 3 , the zinc wire guide wheel 4 , the zinc wire directional wheel 5 and the zinc wire feeding casing 6 into the zinc reduction method polysilicon reactor. A first inert gas inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com