Feeding device for boiling chlorination furnace for producing titanium dioxide by chlorination

A technology of fluidized chlorination furnace and feeding device, which is applied in the direction of titanium tetrachloride, titanium oxide/hydroxide, titanium halide, etc., and can solve the problems of poor continuity of feeding device, blocked feeding pipeline, stuck conveying screw, etc. , to achieve the effect of improving quality, avoiding stratification and improving boiling state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below with reference to the accompanying drawings are exemplary, intended to explain the present invention, but not to be construed as limitations of the present invention, those skilled in the art can change the above-mentioned embodiments within the scope of the present invention , modification, substitution and variation.

[0030] The feeding device 100 for the boiling chlorination furnace of titanium dioxide in the chlorination method according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

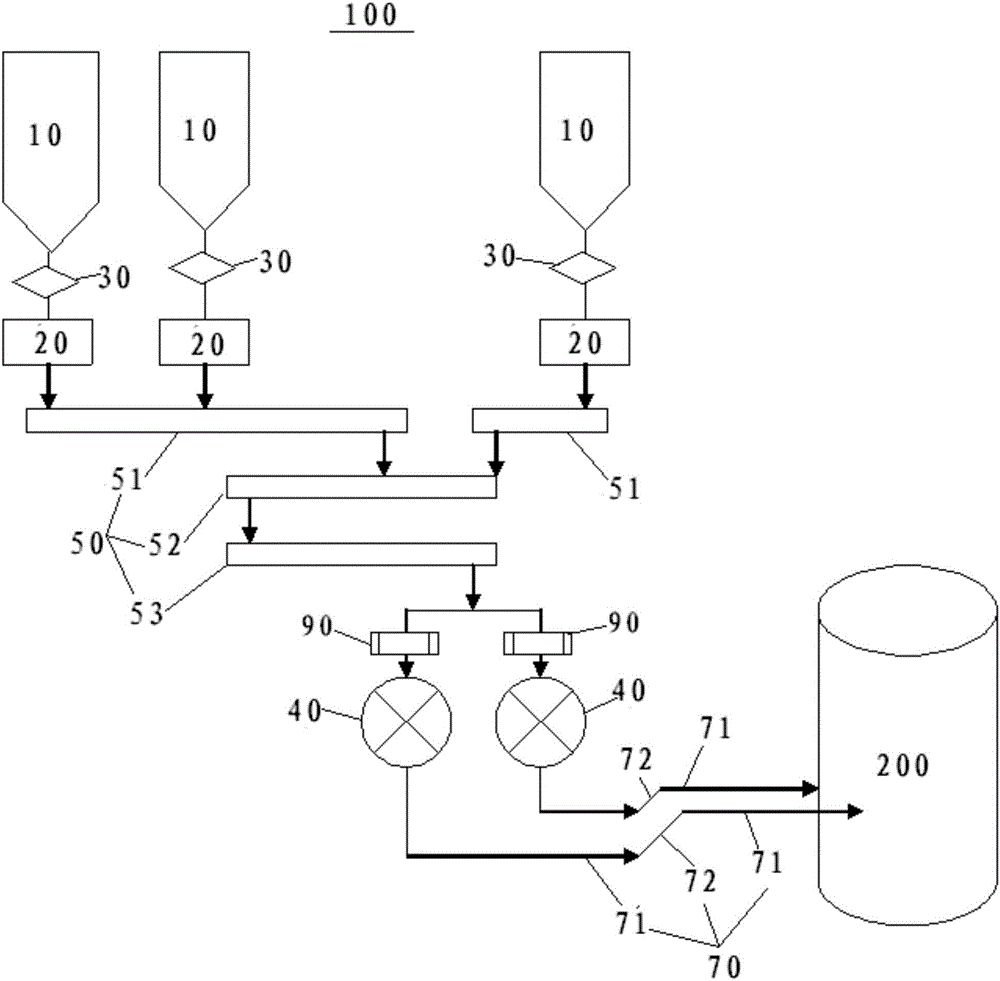

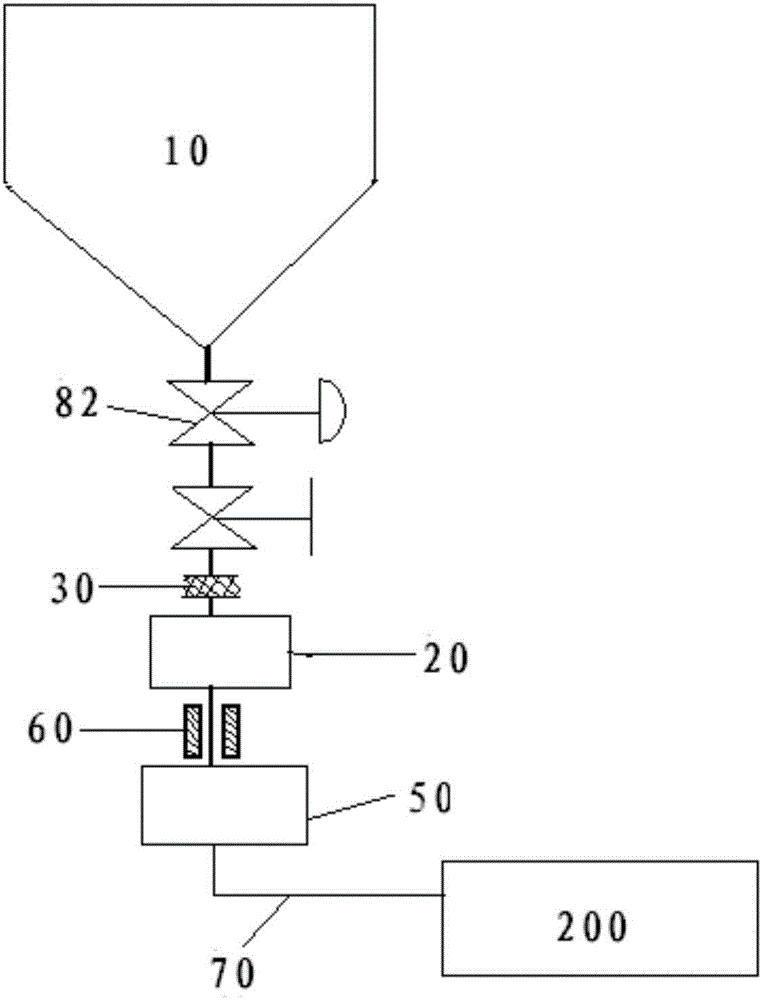

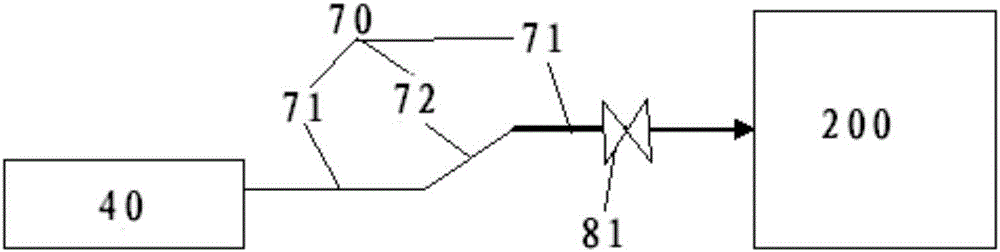

[0031] refer to Figure 1 to Figure 3 As shown, the feeding device 100 of the chlorination process titanium dioxide fluidized chlorination furnace according to the embodiment of the present invention may include three feed bins 10, three weighing devices 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com