Grouting structure capable of filling soluble crystal and construction method

A construction method and grouting technology, which can be used in basic structure engineering, excavation, soil protection, etc., and can solve problems such as difficulty in controlling grouting pressure, failure of negative pressure drainage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

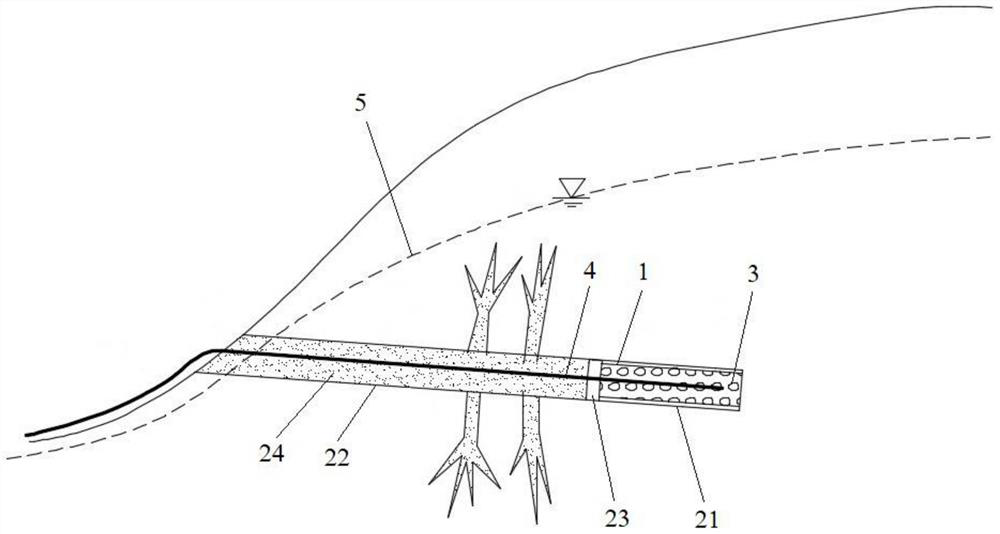

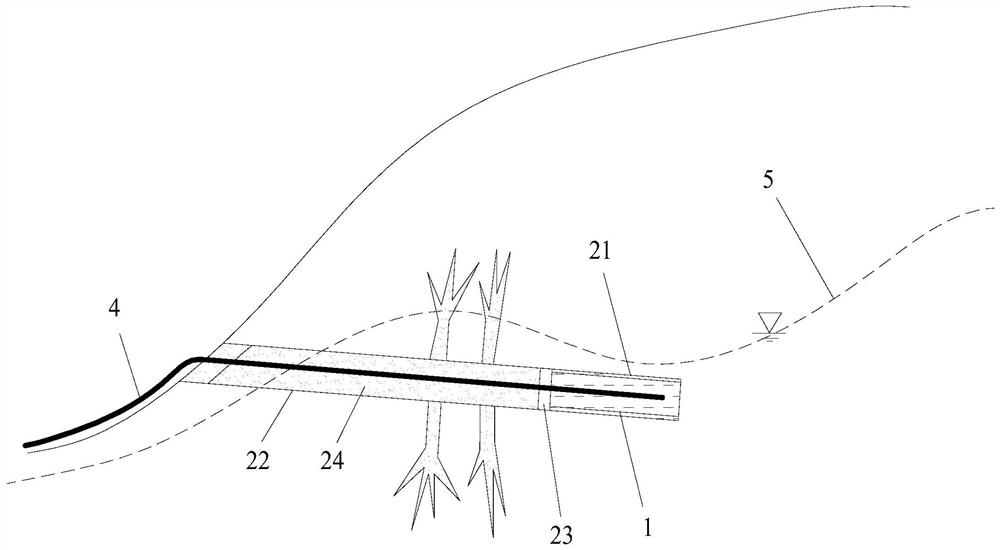

[0037] Such as figure 1 As shown, a grouting structure filled with soluble crystals according to the present invention includes a permeable section 21 and a grouting section 22, a water-stop member 23 is arranged between the permeable section 21 and the grouting section 22, and the permeable The section 21 is provided with a permeable pipe 1 filled with solid soluble crystals 3, and the permeable section 21 is provided with a water inlet of a drainage pipe 4, and the elevation of the water inlet of the drainage pipe 4 is higher than The elevation of the water outlet of the drain pipe 4, the head of the drain pipe 4 is less than the height of the water column corresponding to the local atmospheric pressure.

[0038] Specifically, the diameter of the borehole should be greater than 90 mm. The permeable pipe 1 can be a perforated corrugated pipe with outer woven filter cloth and inner support HDPE, which can prevent large particles such as coarse sand and gravel from entering. Th...

Embodiment 2

[0041] A construction method of a grouting structure filled with soluble crystals according to the present invention adopts a grouting structure filled with soluble crystals as described in Example 1, comprising the following steps:

[0042] a. According to the geological survey, drill a downwardly inclined borehole, and make the permeable section 21 of the borehole be located below the groundwater level 5 controlled by the slope; The position of section 21, the height difference between the bottom of the borehole and the opening of the borehole is less than the height of the water column corresponding to the local atmospheric pressure, so as to ensure that the lift of the drain pipe 4 meets the requirements;

[0043] b. Set the permeable pipe 1 in the permeable section 21, and then insert the drain pipe 4 in the permeable pipe 1, so that the port of the drain pipe 4 goes deep into the bottom of the permeable pipe 1;

[0044] c. Fill the water-permeable pipe 1 with solid solub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com