Method for filling underground cavity of bedrock stratum through filler grouting and hydraulic filling device

An underground cavity and hydraulic filling technology, applied in underground chambers, shaft equipment, earthwork drilling and mining, etc., can solve problems such as ground subsidence and hidden safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

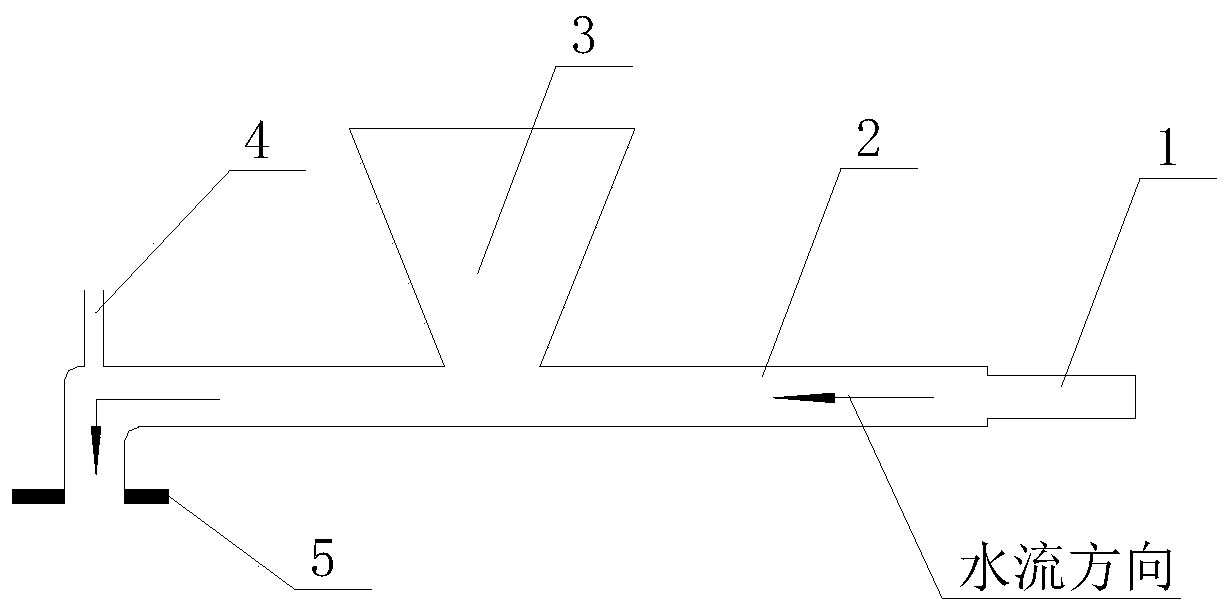

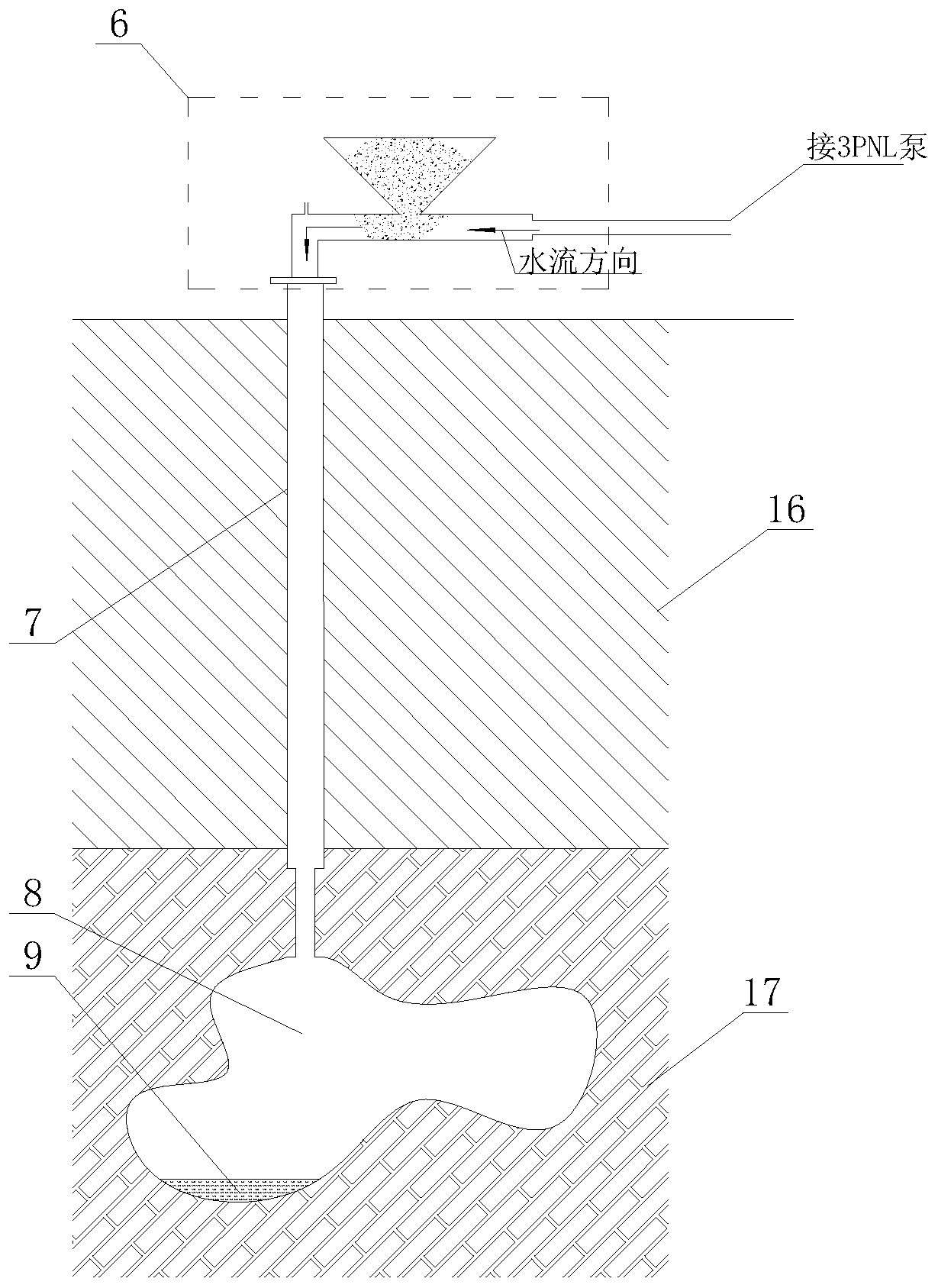

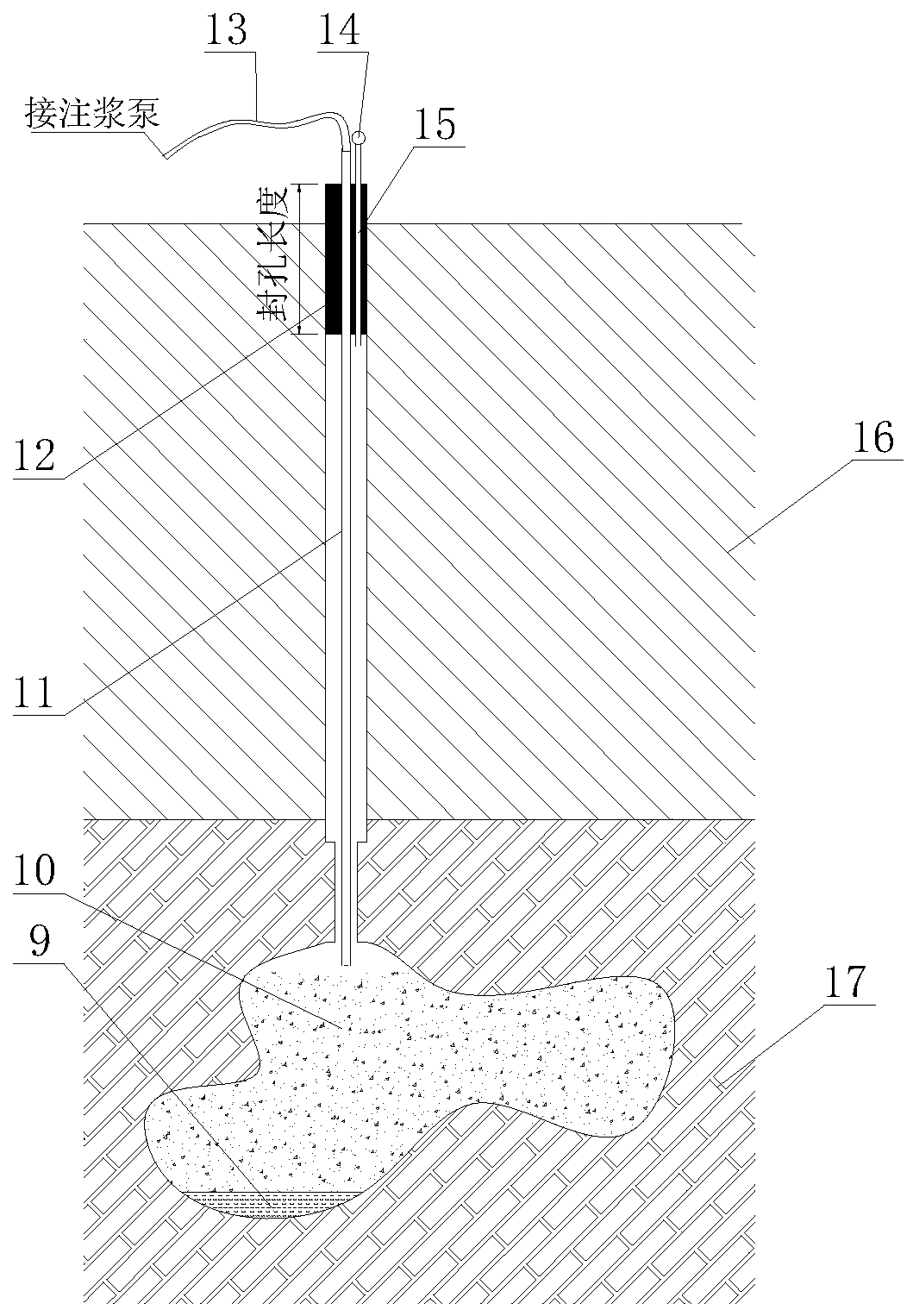

Method used

Image

Examples

Embodiment 1

[0057] Tangshan City is located in a shallow buried area with developed karst fissures. Historically, dynamic changes in groundwater have damaged the Quaternary overburden structure to varying degrees, and many karst collapses have occurred. The Tangshan City Stadium Karst Collapse Geological Disaster Control Project adopts the method described in the present invention to implement karst collapse control, and takes the J2 karst control hole as an example to illustrate the implementation process of the method for filling the covered karst cave with filler grouting in the present invention.

[0058] The karst survey shows that the Quaternary covering soil layer at the J2 hole is 39.8m thick, the bedrock is underneath it, and the cave is at 45.1-55.7m, and there is no filling in the cave.

[0059] (1) Determine the location of the drill hole: This project uses the survey hole during the karst survey, and the drill hole is arranged directly above the karst cave.

[0060] (2) Drill...

Embodiment 2

[0070] The goaf management area of Senze Coal and Aluminum Co., Ltd. is located in Liulin County, Shanxi Province. The management area is about 150m long from east to west and about 45m wide from north to south. It is a roadway excavated for private bauxite mining in the 1990s. Due to the subsidence of the roadway, subsidence has occurred on the surface, resulting in cracks in the road and cracks in the mountain. Adopt the method described in the present invention to carry out treatment, according to the design scheme, carry out filler grouting treatment to the treatment area that has been found out (preliminary layout hole 14, motorized hole 3). Taking Z3 governance hole as an example to illustrate the implementation process of the method of the present invention.

[0071] The hole at the Z3 hole is a mining roadway, and the roadway direction is basically north-south. The roadway section is horseshoe-shaped, with a height of about 2.0m, a width of about 2.0m, and a buried d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com