Ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock

A long-distance, pre-grouting technology, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of poor working environment at the construction site, inability to use large-scale equipment, and limited grout diffusion distance, etc., to achieve good reinforcement effect and solidification Time is controllable and the effect of improving the construction environment of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this embodiment, the ground pre-grouting reinforcement process of the surrounding rock of the deep and long-distance roadway includes the following steps:

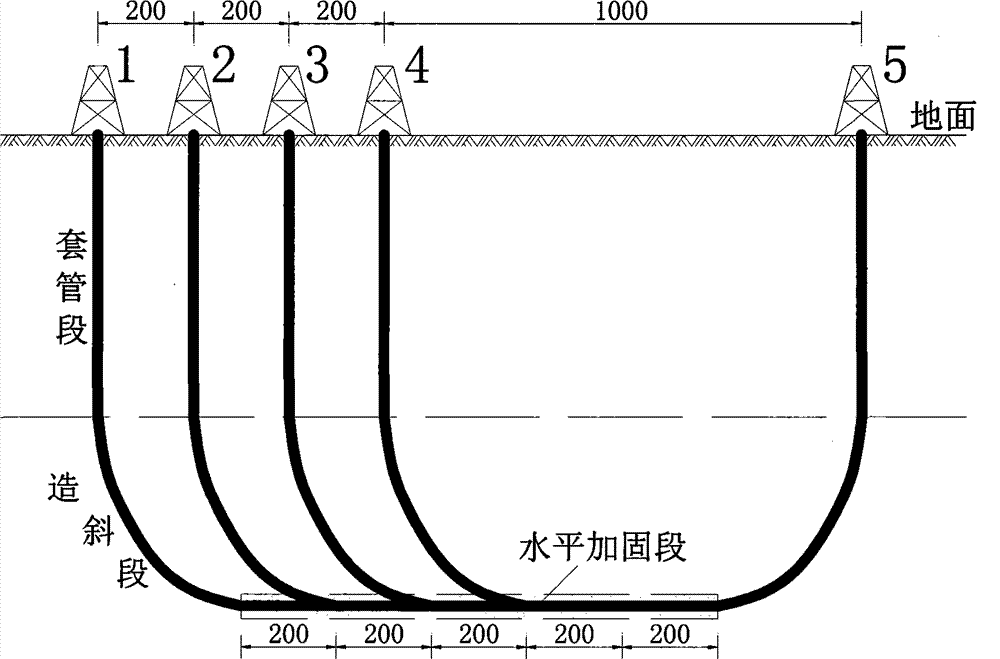

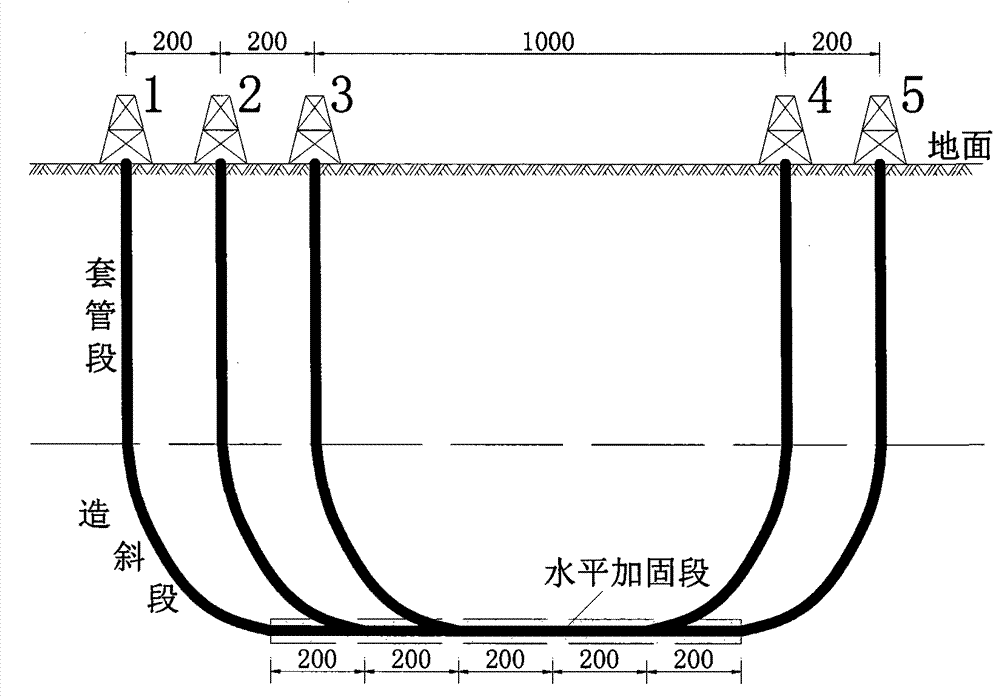

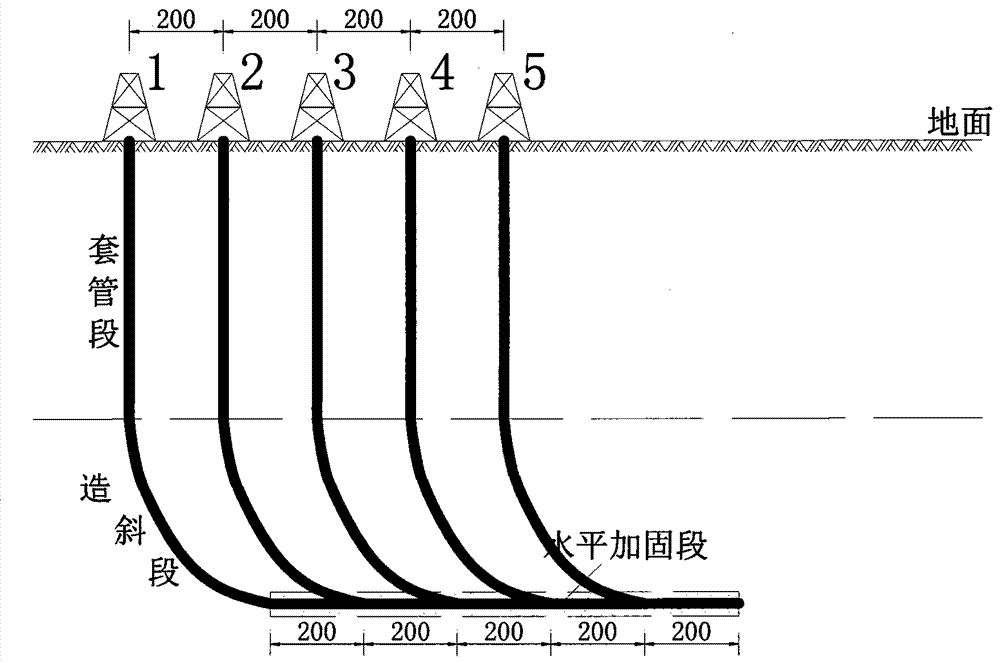

[0029] (a) Use a drilling rig to open ground grouting drilling holes on the ground. The ground grouting drilling includes a casing section, a deflection section and a horizontal reinforcement section. The surface entrance of the open hole and ground grouting drilling is arranged along the direction of the roadway; the depth of the bottom opening of the casing section entering the stable bedrock is greater than or equal to 10m, the specification of the casing is Φ168*8mm seamless geological pipe, and the drilling of the casing section of the straight hole The hole deviation rate is less than or equal to 3‰, and the distance between the ground entrances of two adjacent ground grouting drilling holes is 200 meters; the curvature of the drilling trajectory in the deflection section is 5° / 30m; the apex angle of the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com