Method for controlling water inrush and sand inrush under coal mine

A water inrush and sand breaking technology, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., to achieve the effects of not being easy to waste holes, saving engineering costs, and reducing slurry consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following describes the present invention in detail with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

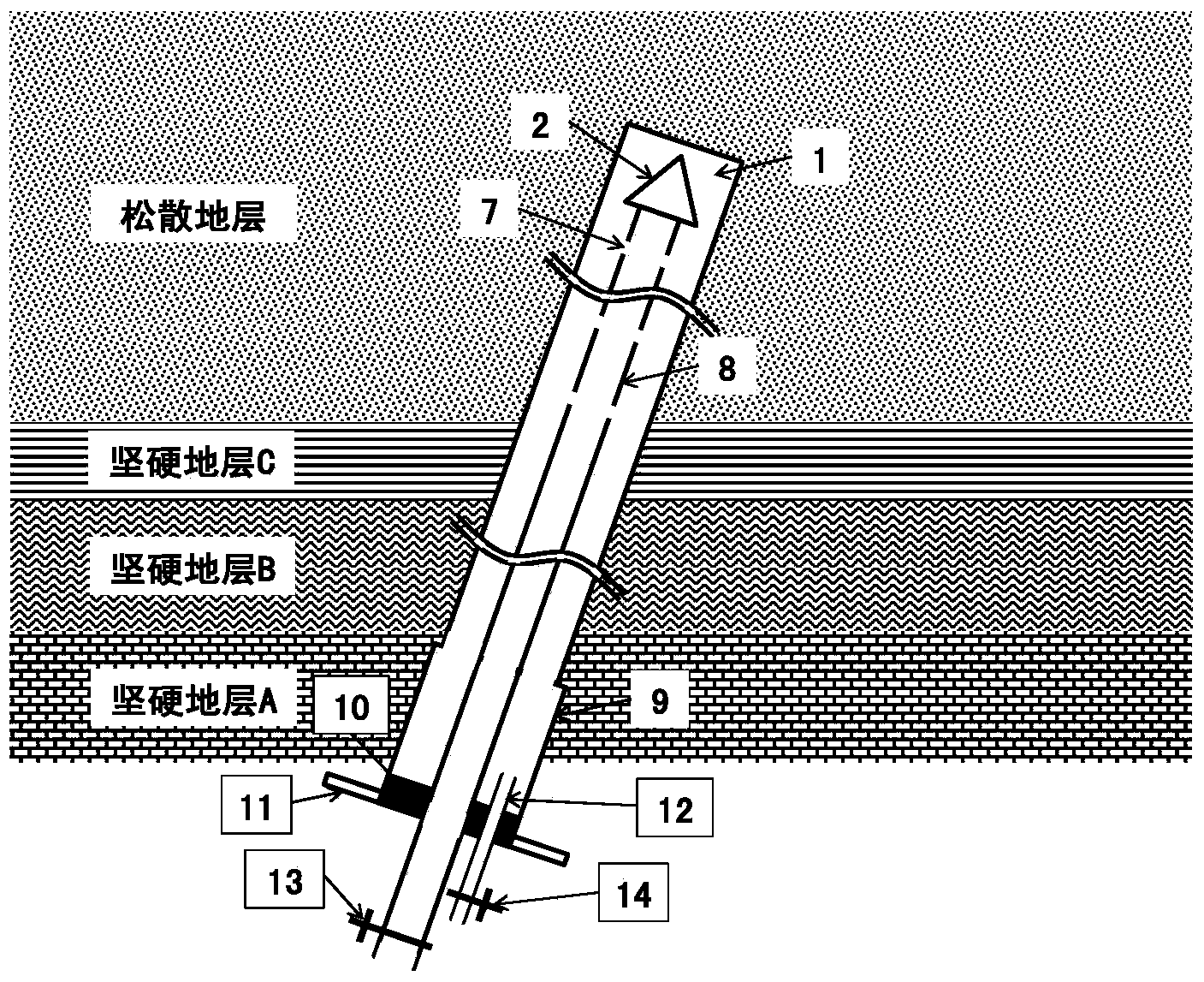

[0025] A method for preventing water inrush and sand burst in underground coal mines includes four parts: a grouting pipe is installed under a disposable drill bit, the drill cap of the disposable drill bit is separated from the drill body, consolidating the grouting pipe and grouting into a specific formation.

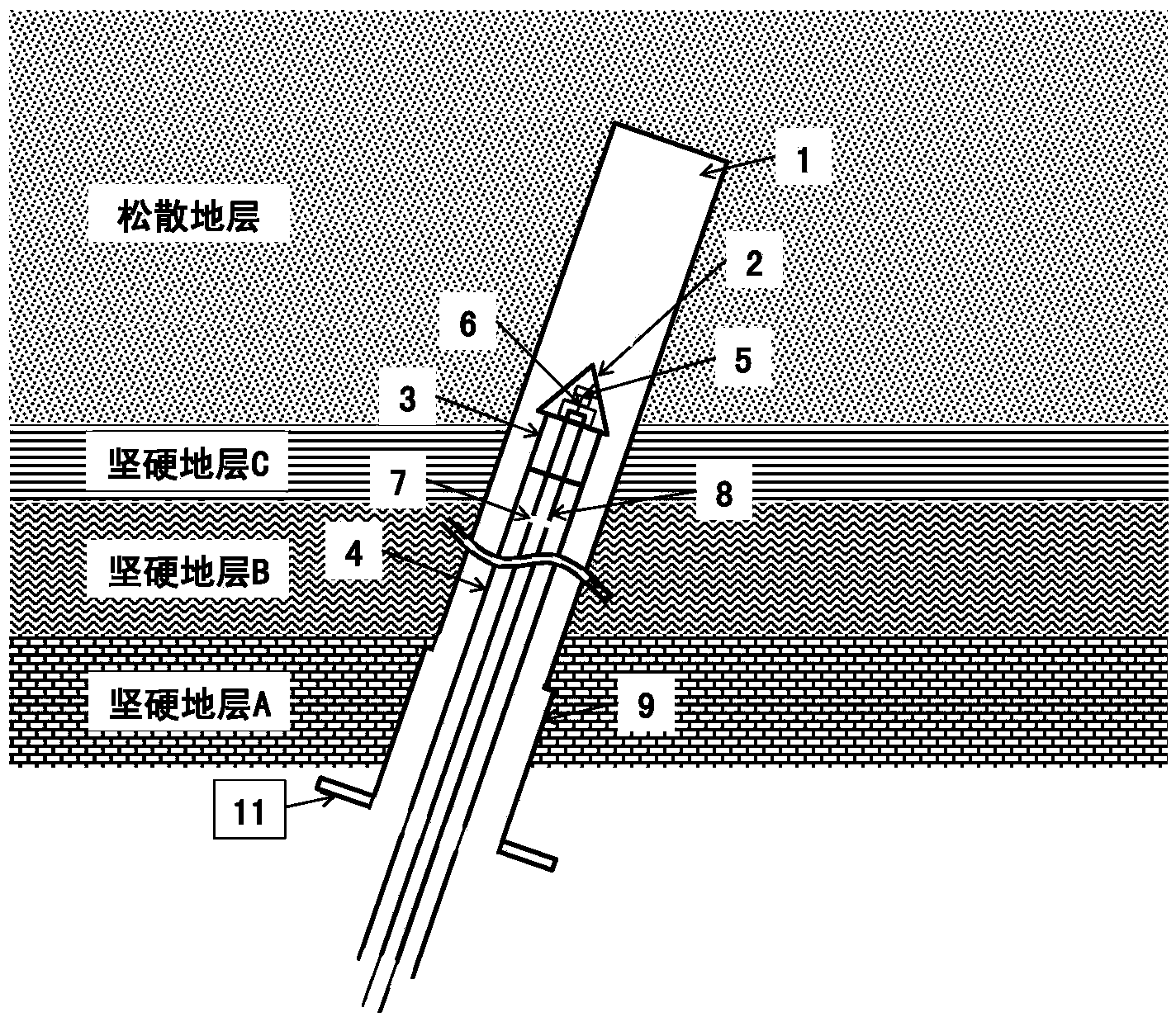

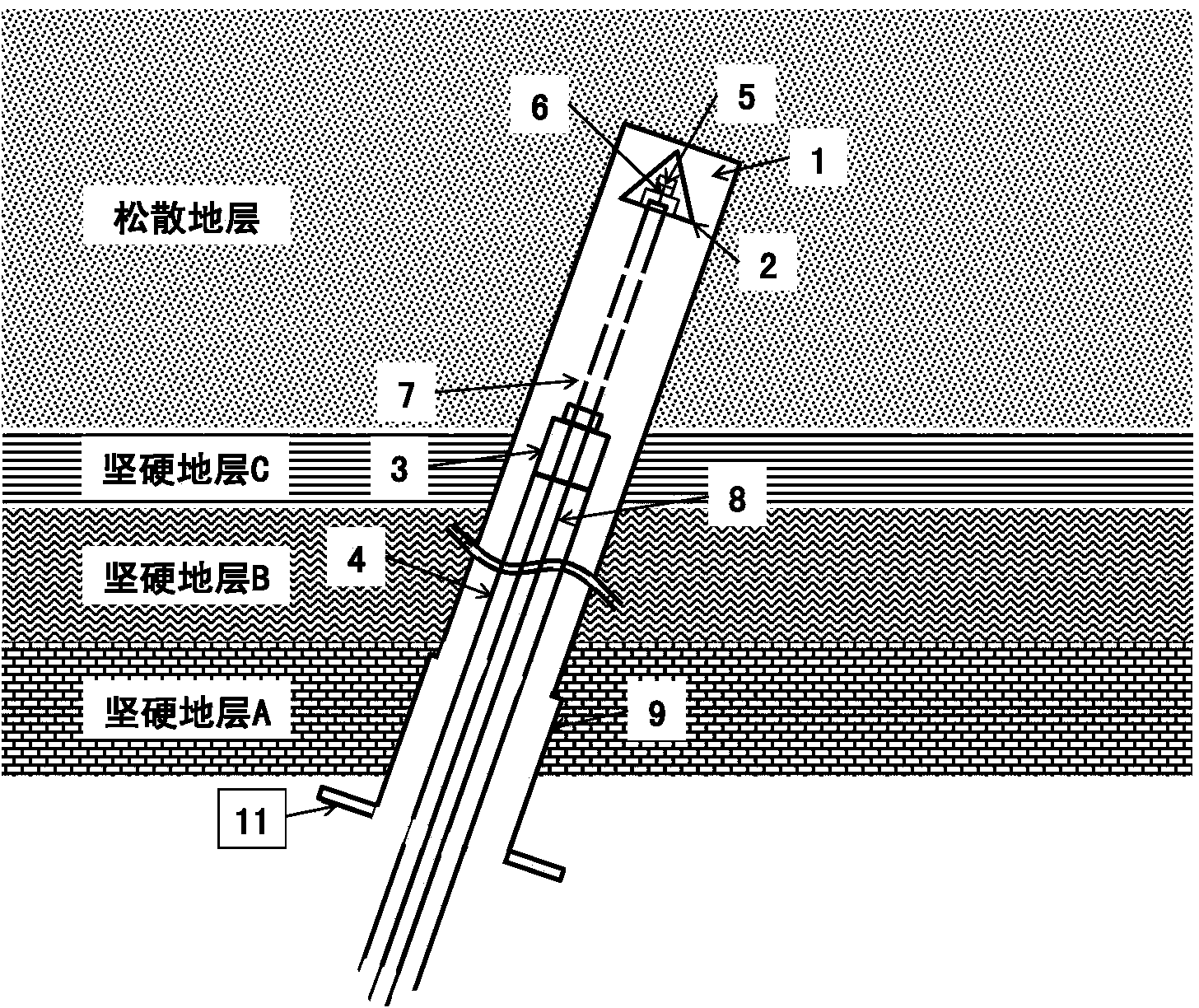

[0026] The first step is to set up a grouting pipe with a disposable drill bit: such as figure 1 As shown, the disposable drill body 3 is connected to the drill pipe 4, the grouting pipe 8 passes through the through hole in the drill pipe 4, and the disposable drill cap 2 and the grouting pipe 8 are connected to the drill connector 6 through the grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com