Mining hand hole-sealing pump

A technology for hole sealing and mining. It is used in pumps, piston pumps, machines/engines, etc. It can solve problems such as unsuitable locations without electricity underground, equipment requiring electricity, and unsatisfactory effects, achieving wide practicability and improving performance. Grouting pressure, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

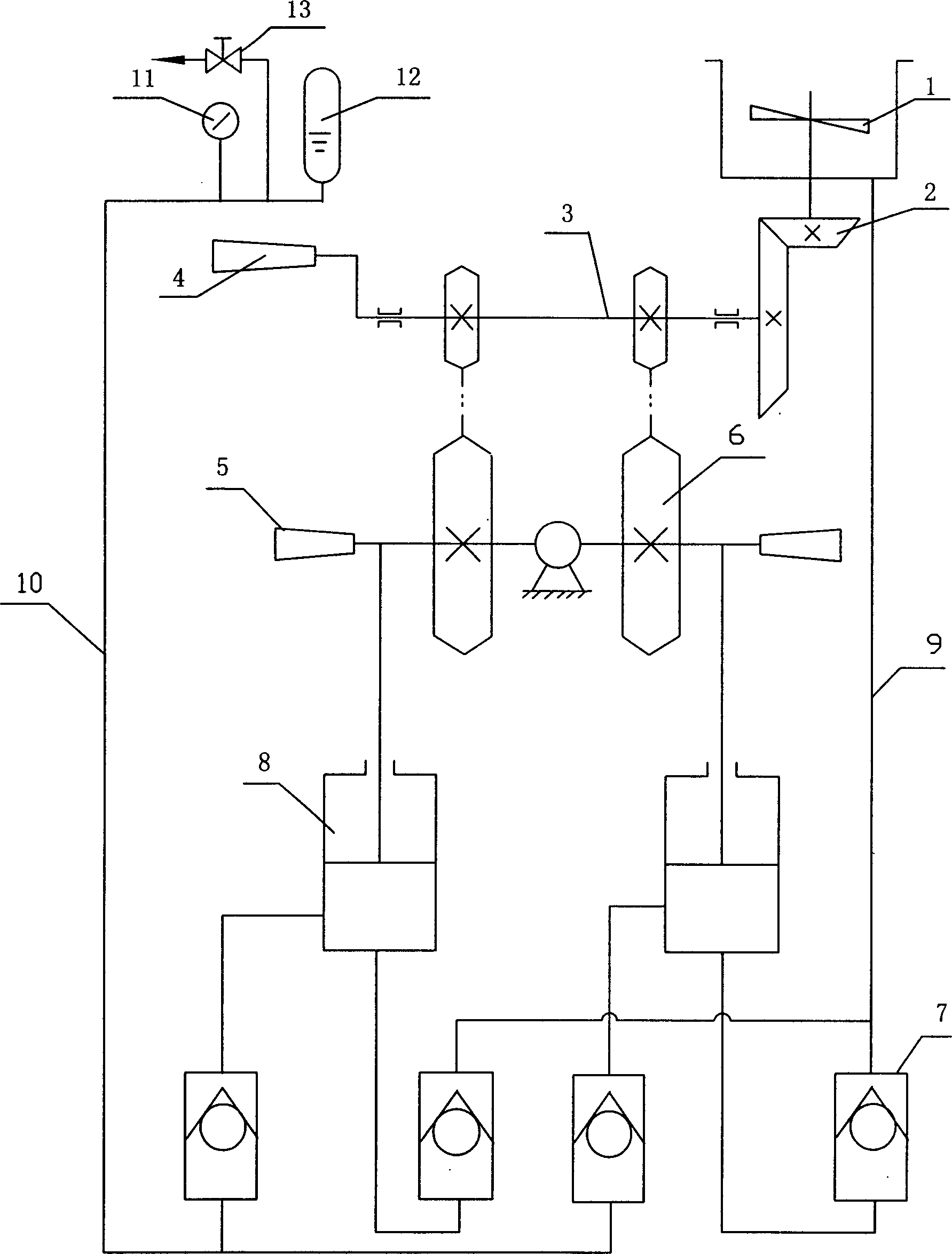

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0010] The manual hole sealing pump for mining of the present invention mainly consists of an agitator 1 for sealing slurry material, a bevel gear set 2, a chain gear set 3, a hand wheel 4, a pressure rod 5, a check valve 7, a plunger pump 8 and a pump. Slurry valve 13 constitutes. It is divided into two parts: stirring device and mud conveying device. The stirring device includes agitator 1, bevel gear set 2 connected with agitator 1, bevel gear set 2 is connected with transmission shaft 3, bevel gear set 2 includes driving wheel and driven wheel , driving wheel is that bull wheel is located at transmission shaft 3 bearing seats outside one end, and driven wheel is that small wheel is located on the rotating shaft of agitator 1. The other end of the outer side of the transmission shaft 3 support seat is provided with a shaking handle 4 that drives the bev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com