Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

A technology of high-pressure grouting and construction method, applied in the field of geotechnical engineering, can solve the problems of failure to achieve the purpose of grouting, high flow rate, and large groundwater dynamic water pressure, achieve the effect of grouting and water plugging reinforcement, control water resources, The effect of increased consolidation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] A kind of embodiment of construction method of the present invention is:

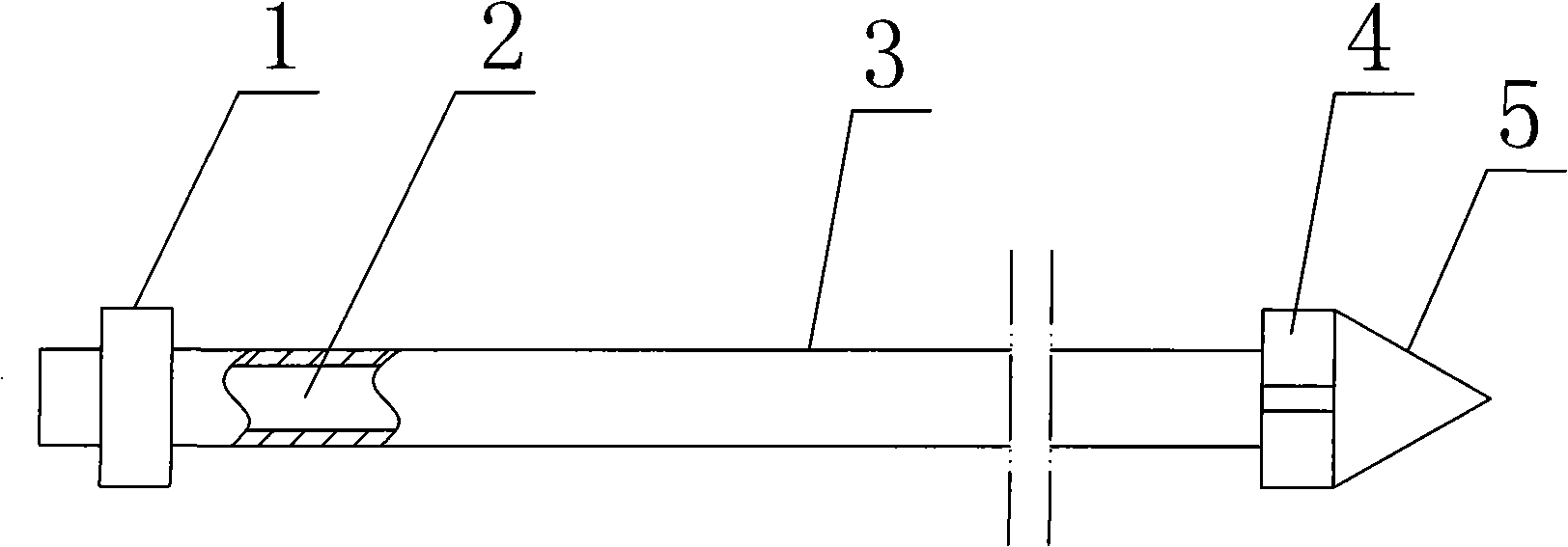

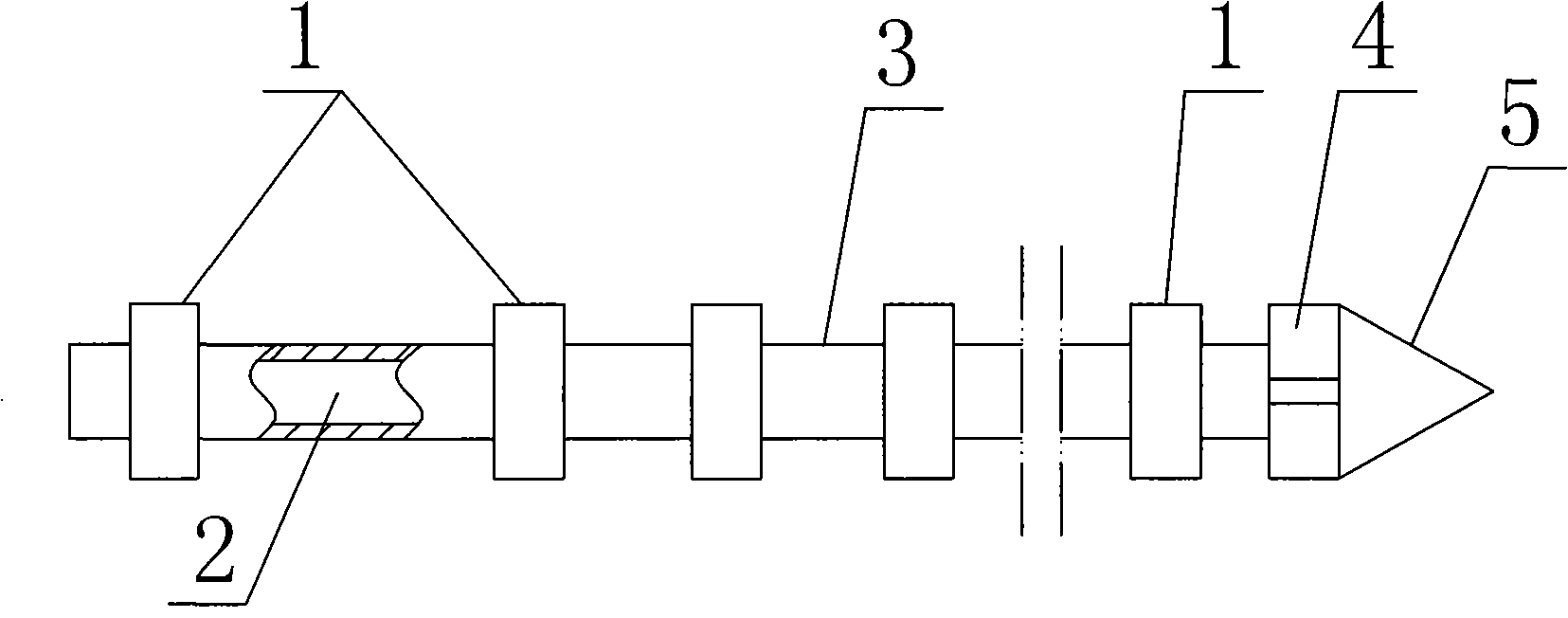

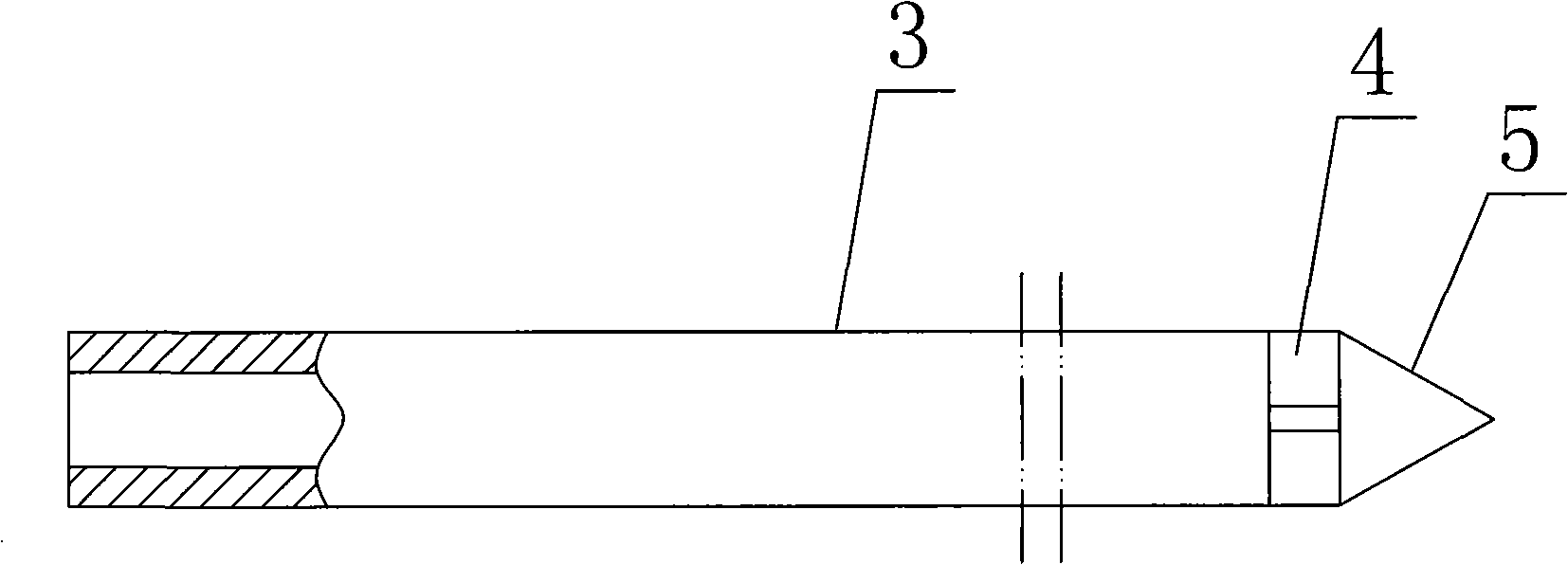

[0073] (1) Drilling: According to the formation conditions, different drilling tools ( Figure 1 ~ Figure 3 ). Rotary drilling is adopted in the quicksand layer, and the YT-1 type drilling machine is used to form the hole. The drill bit is equipped with a water guide head. The diameter of the hole is generally φ42mm, and the vertical accuracy should be less than 1%. , without coring. The drill pipe is made of φ28 steel pipe. The drill pipe can be used as a grouting pipe without pulling out the pipe. The drilling speed is fast and the efficiency is high. The principle of penetration testing is to hammer the drill pipe into the formation. The drilling method has a small borehole diameter and is easy to avoid larger rocks in the gravel layer, and solves the common problems of hole collapse, slurry leakage, and difficulty in footage in the quicksand layer and gravel layer of the conventional drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com