Combined bearing double-layer well wall and construction method thereof

A construction method and technology for outer well wall, which are applied in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problem of inability to improve the filling effect of inter-wall grouting on the seepage channel of well wall, etc., and achieve a favorable grouting effect. , Improve the sealing water performance and increase the effect of grouting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

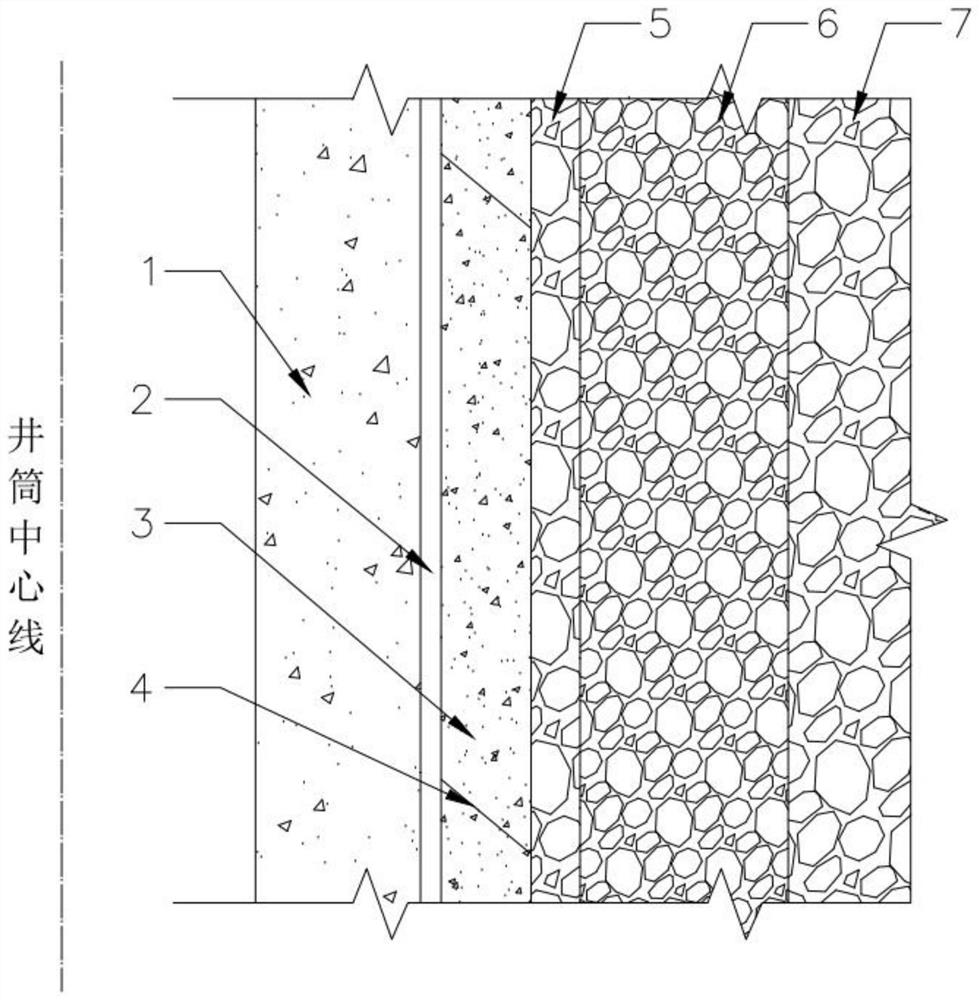

[0028] A double-layer shaft wall with combined bearings, including an inner shaft wall 1 and an outer shaft wall 3, the outer shaft wall 3 is excavated and poured in sections, and there are construction joints 4 between the sections of the outer shaft wall 3; The well wall 1 is formed by continuous pouring; there is a gap between the inner well wall 1 and the outer well wall 3 , and a micro-expansion grouting material is injected into the gap to form a micro-expansion interlayer 2 .

[0029] In this embodiment, the inner shaft wall 1 is formed by continuous pouring from bottom to top using low-heat of hydration micro-expansion concrete that meets the design strength.

[0030] Wherein, the outer shaft wall 3 is poured in sections from top to bottom, and there are construction joints 4 between adjacent sections of the shaft wall. The inner shaft wall 1 is poured continuously from bottom to top, without construction joints 4, and the integrity is good.

[0031] In this embodimen...

Embodiment 2

[0039] This embodiment is a construction method for manufacturing the joint bearing double-layer well wall provided in embodiment 1, including the following steps:

[0040] S10. Excavating in sections from top to bottom and pouring the outer well wall 3 .

[0041] S20. Continuously pouring the micro-expansion inner shaft wall 1 from bottom to top; during the pouring process, multiple groups of grouting pipes are pre-buried vertically on the inner shaft wall 1 for the later inner shaft wall and outer shaft wall grouting in between.

[0042] In another embodiment, after the pouring of the inner well wall 1 is completed, multiple sets of grouting pipes are installed by drilling vertically spaced holes in the inner well wall 1 for later grouting between the inner well wall and the outer well wall. .

[0043] S30. After the construction of the inner well wall 1 is completed, the micro-expansion grouting material is injected between the inner well wall 1 and the outer well wall 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com