Gas pressure measuring device and gas pressure measuring method

A pressure measuring device and gas technology, applied in measurement, earthwork drilling, borehole/well components, etc., can solve problems such as limited sealing and inaccurate gas pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

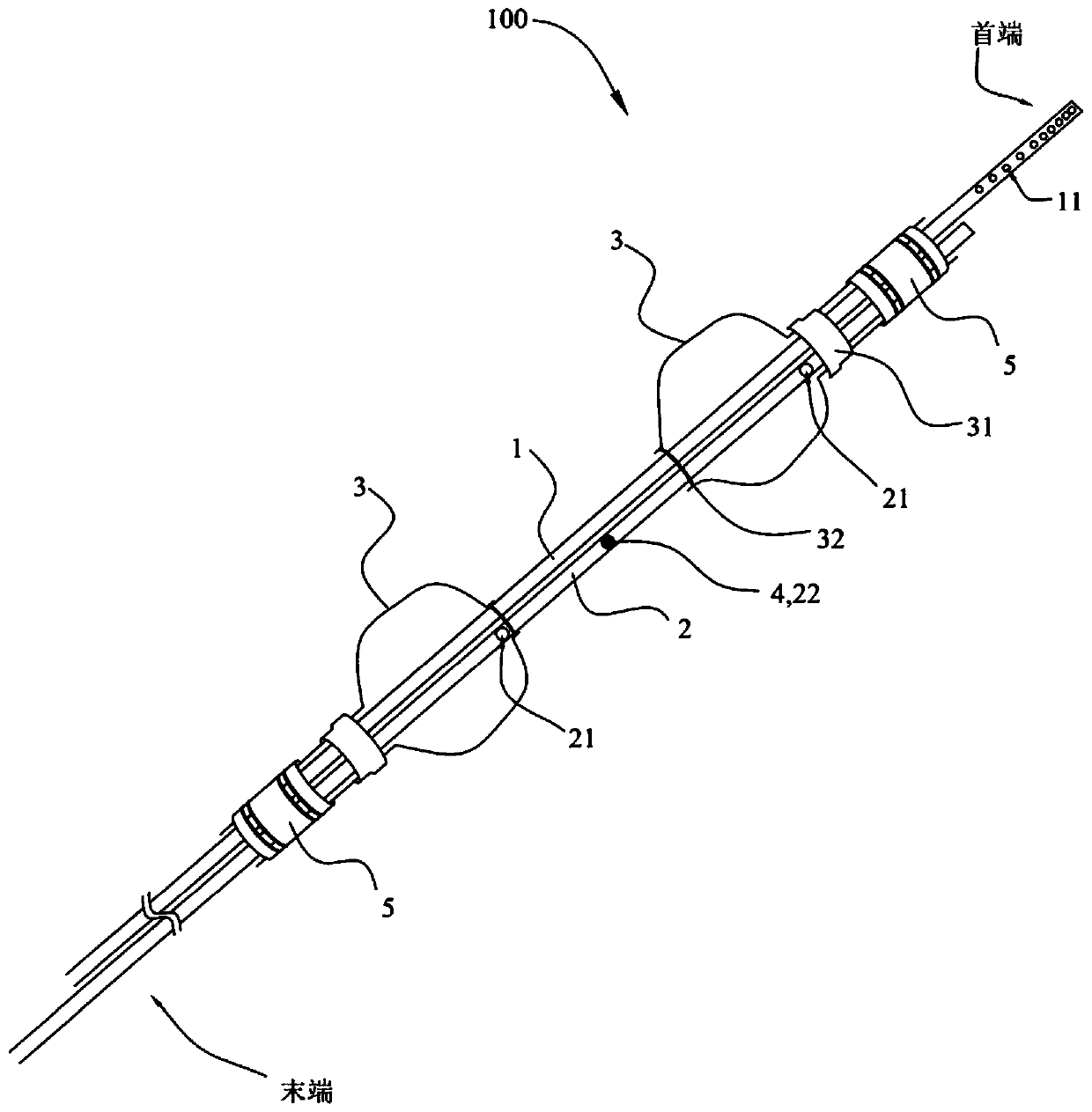

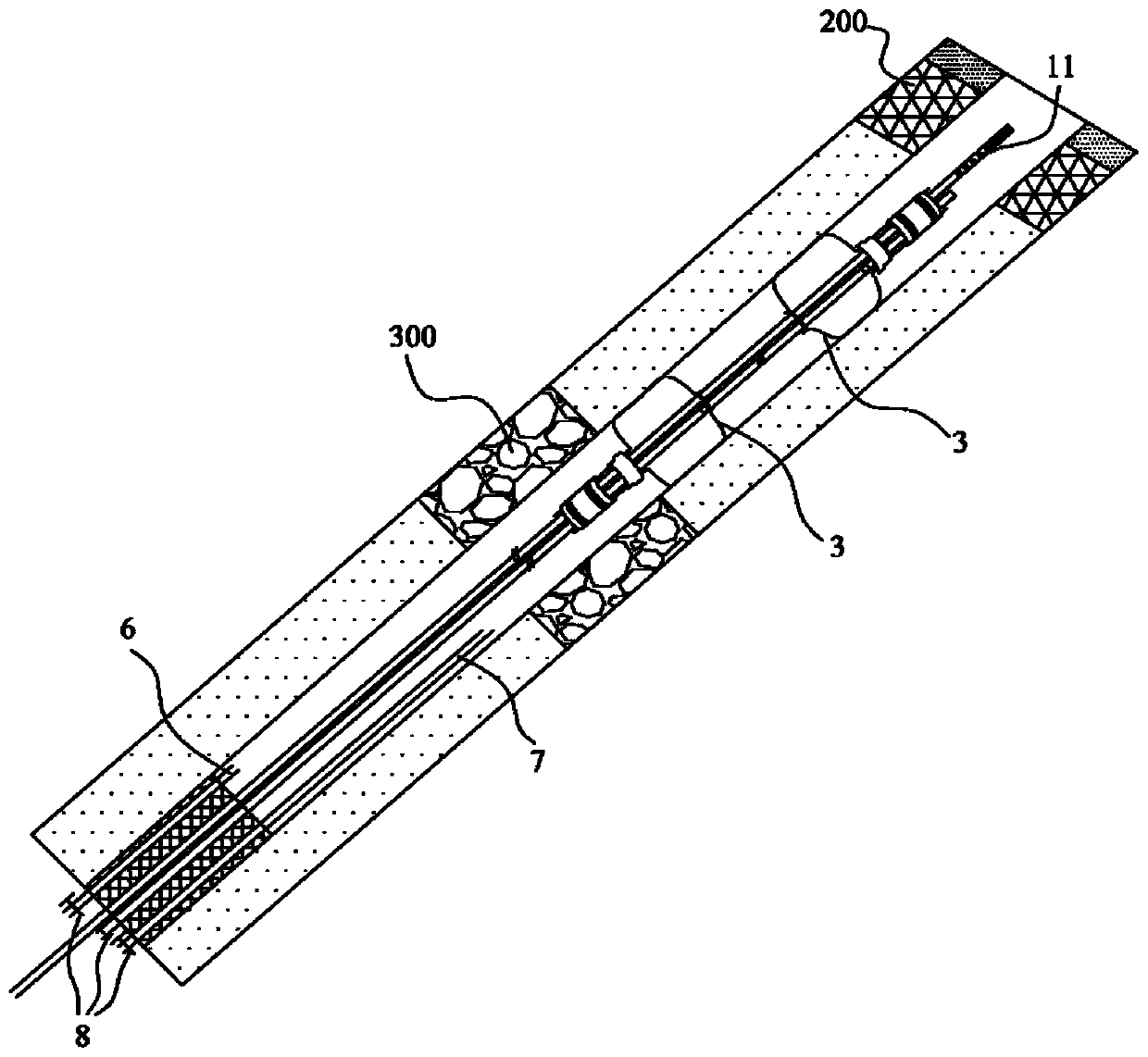

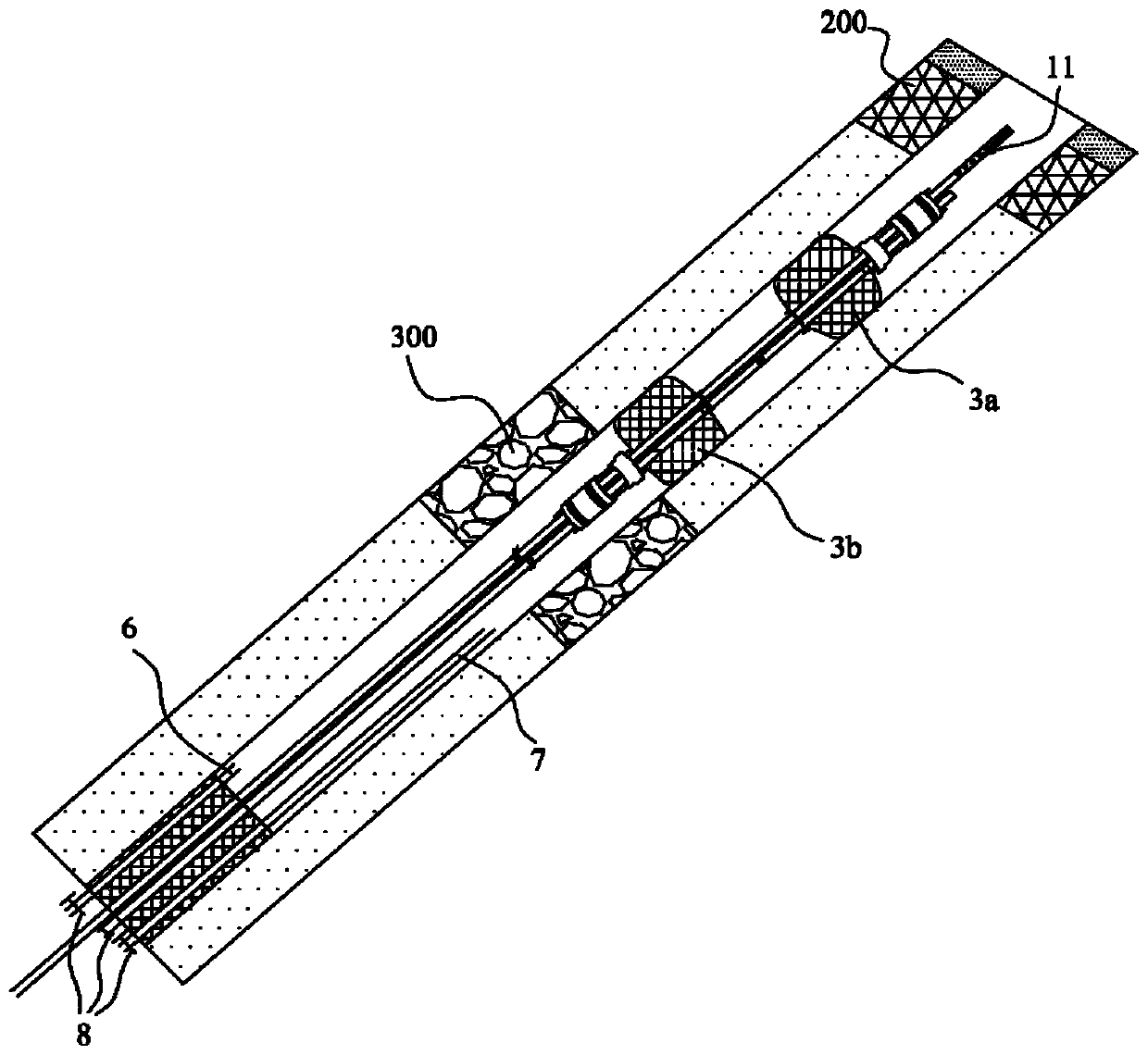

[0059] figure 1 A schematic diagram of a gas pressure measuring device provided in an embodiment of the present invention; figure 2 A schematic diagram of the gas pressure measuring device installed in the pressure measuring borehole provided by the embodiment of the present invention; image 3 A schematic diagram of the gas pressure measuring device provided by the embodiment of the present invention after the first grouting; Figure 4 A schematic diagram of the gas pressure measuring device provided by the embodiment of the present invention after the second grouting; Figure 5 A schematic diagram of the gas pressure measuring device provided by the embodiment of the present invention after the third grouting; Figure 6 A schematic diagram of the gas pressure measuring device provided by the embodiment of the present invention after the fourth grouting; Figure 7 It is a schematic diagram of pressure measurement performed by the gas pressure measurement device provided b...

Embodiment 2

[0083] Figure 8 The flow chart of the gas pressure measurement method provided by the embodiment of the present invention Figure 1 ; Figure 9 The flow chart of the gas pressure measurement method provided by the embodiment of the present invention Figure II .

[0084] Such as Figure 8 As shown, the embodiment of the present invention provides a gas pressure measurement method, including:

[0085] S100. Perform the first grouting through the first grouting pipe and the grouting bag.

[0086] S200. Perform the second grouting through the first grouting pipe and the switching device.

[0087] S300. Obtain the gas pressure through the pressure measuring tube 1.

[0088] Such as Figure 1-7 As shown, in the gas pressure measurement method provided by the embodiment of the present invention, the gas pressure measurement device 100 provided by this embodiment, the first grouting pipe 2 is arranged in parallel with the pressure measurement pipe 1, and the first grouting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com