Fully mechanized mining face construction region deep hole staging pressurization grouting method

A fully mechanized mining face, staged technology, applied to mining equipment, earthwork drilling, wellbore lining, etc., can solve problems affecting work efficiency, insufficient, uneven slurry diffusion, etc., to ensure the grouting effect, increase the Diffusion radius, effect of improving grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

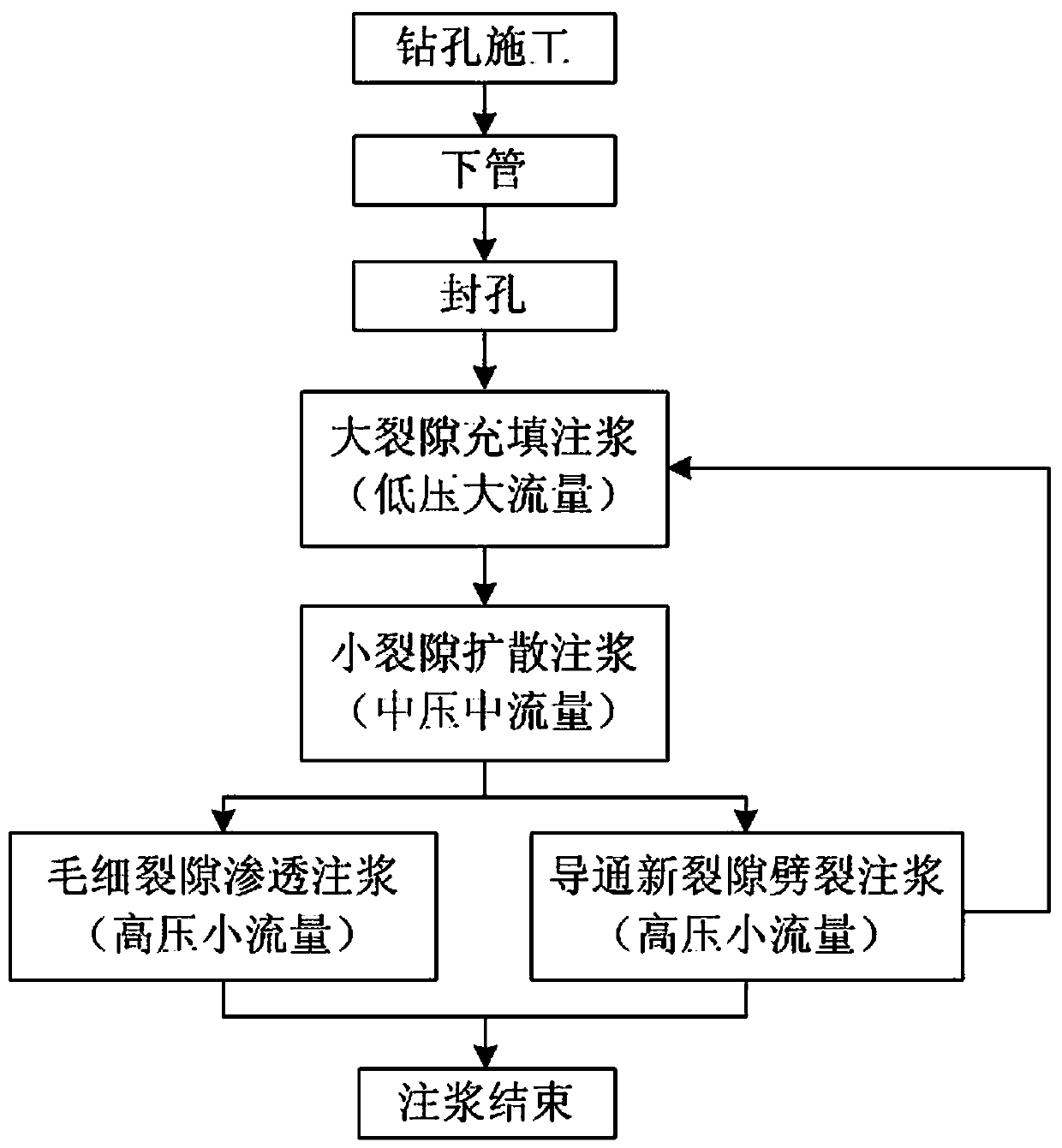

[0023] Such as figure 1 As shown, a method of pressurized grouting in deep holes in the structural area of a fully mechanized mining face in stages, including construction grouting drilling, pipe lowering, hole sealing, and grouting;

[0024] Specifically: construction grouting drilling, the construction area is 50-100m ahead of the working face, the hole diameter is 75mm, and the final hole position of the drilling passes through the abnormal area 5m. The above-mentioned abnormal areas are faults, subsidence columns, broken zones and other geological structural areas detected in advance.

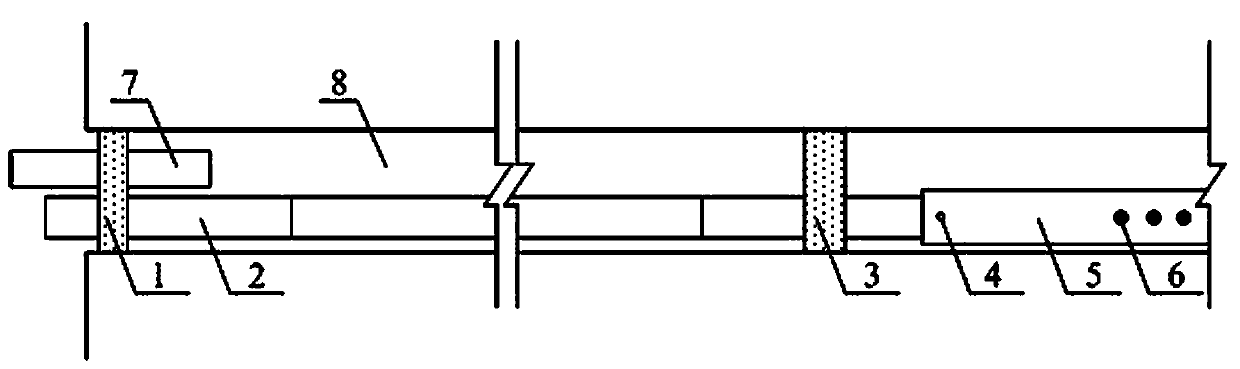

[0025] Such as figure 2 As shown, the lower pipe uses PE pipe 5 and grouting steel pipe 2. The front end of PE pipe 5 is provided with grouting hole 6, and the rear end of PE pipe 5 is provided with counter-perforation 4; grouting steel pipe 2 and PE pipe with grouting hole The pipe 5 is connected, and the PE pipe 5 is located at the front end of the entire grouting pipeline; in the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com