A method of blasting to increase seepage and its application

A technology of blasting holes and regular hexagons, which is applied in blasting and other directions, can solve problems such as large limitations, no effect, and limited seepage enhancement, and achieve the effects of reducing dosage, increasing permeability, and reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] A certain tunnel construction has a coal-piercing section, the coal-rock grade is grade IV, the joints are developed, and the rock mass is rich in gas. The gas emission rate is 0.5m3 / min after monitoring. In order to increase the construction speed and gas discharge speed, the method of blasting to increase seepage is used to increase the permeability of coal and rock, so that the gas can be discharged as soon as possible.

[0030] The construction steps are as follows:

[0031] 1) Determine the distribution position of the pilot holes in the blasting center.

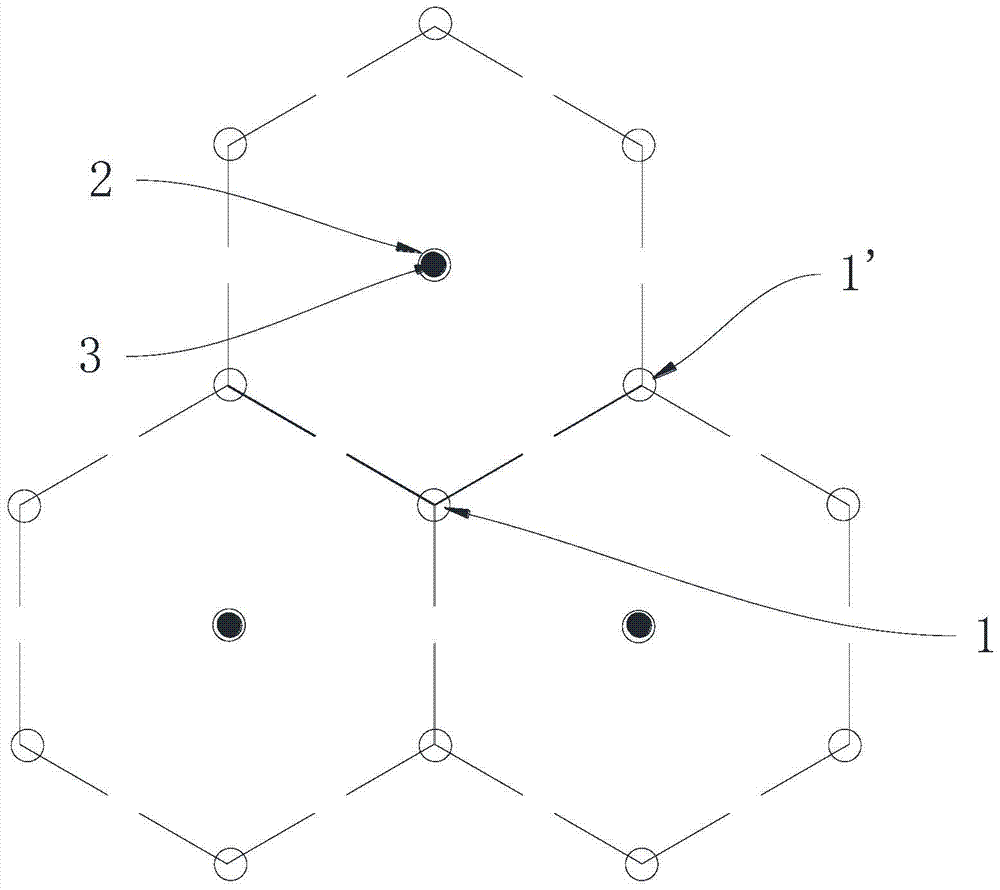

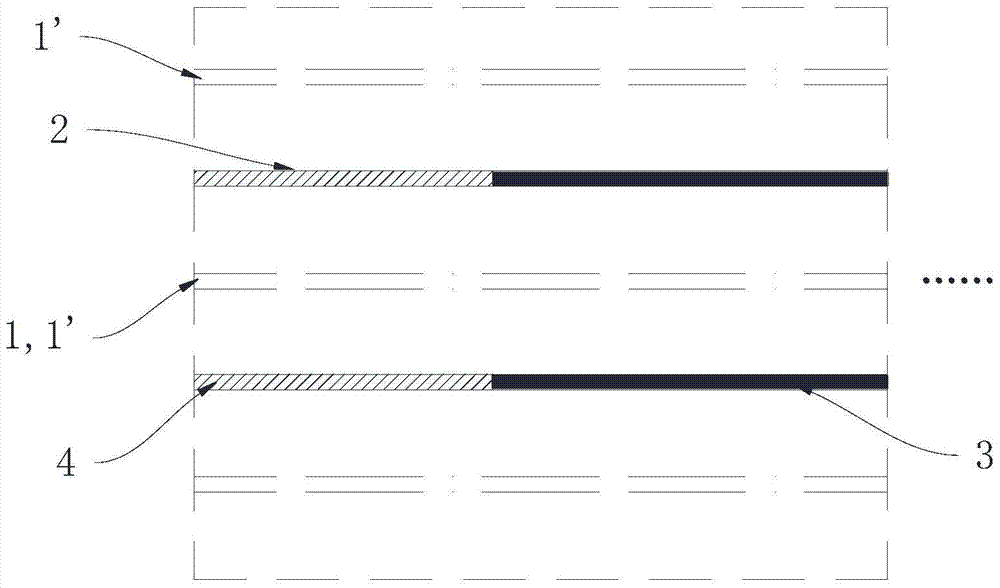

[0032] Determine the center point of the tunnel profile through construction stakeout, and mark it as the center guide hole 1.

[0033] 2) Determine the distribution positions of pilot holes and blast holes.

[0034] Such as figure 1 As shown, take 2m as the side len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com