Support method for coal seam roadway to cross gob

A technology of over-goaf and goaf, applied in coating, tunnel, tunnel lining, etc., can solve the problem of not meeting the stability requirements of surrounding rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

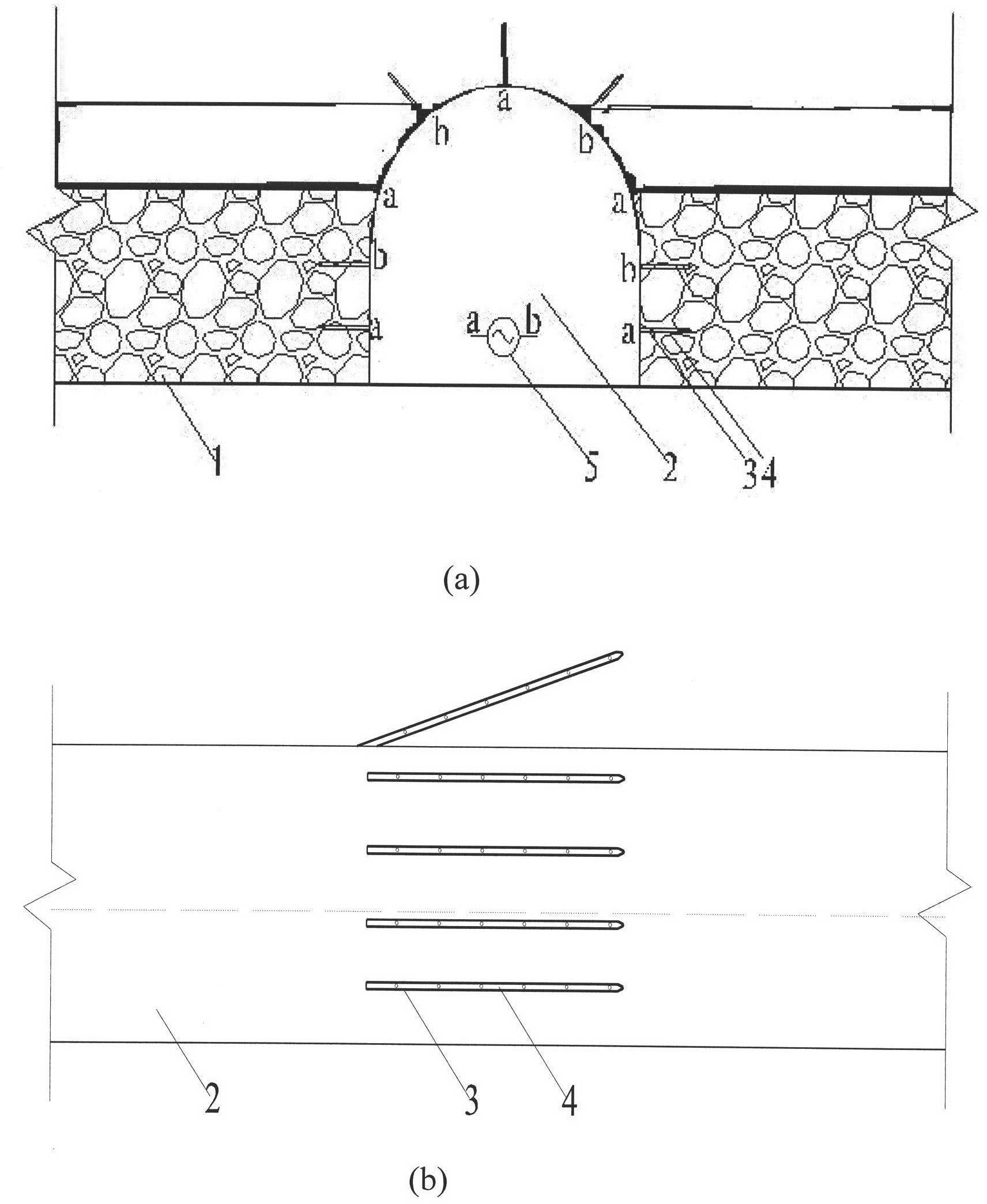

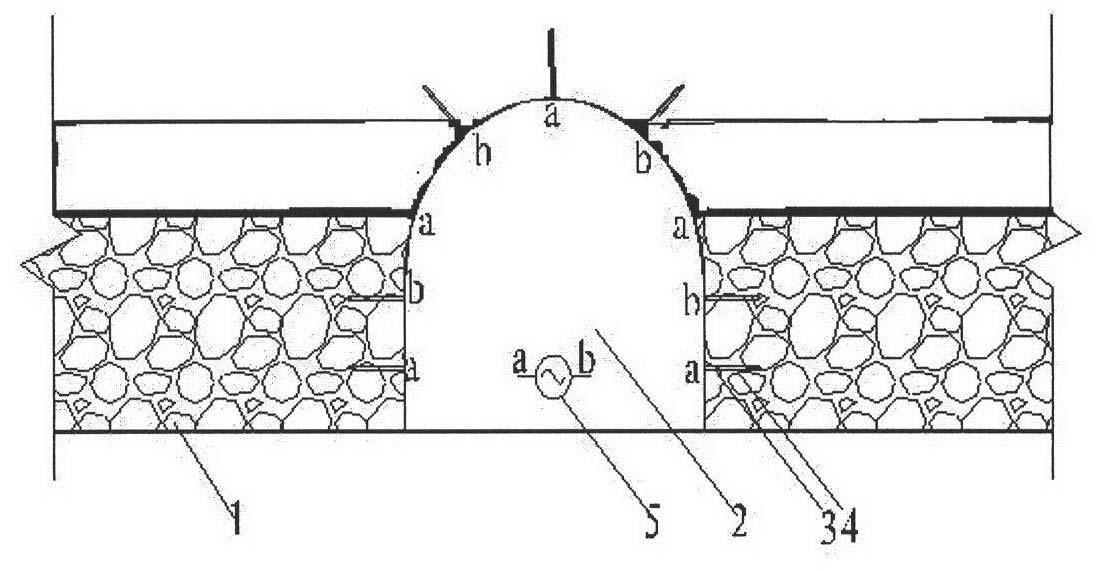

[0018] The support method for the coal seam roadway passing through the goaf under the action of the alternating current electric field of the present invention supports the well bottom depot passing through the gob. The support process is:

[0019] I, first to a certain mine 15 # The regenerated surrounding rock in the goaf beyond the outline of the coal seam bottom depot is temporarily supported, and the small guide pipe is driven in advance according to the outer insertion angle of 15° and the circumferential spacing of 600mm, and the length of the small guide pipe is 1600mm;

[0020] II. Build an AC electric field grouting system. The main components of the system include the regenerated surrounding rock in the goaf, the bottom hole parking lot, a small conduit, cement slurry and an AC electric field;

[0021] III. Inject cement slurry into the small conduit, apply an AC electric field, the voltage is 660V, and the admixture is an acidic electrolyte Na 2 SiO 3 , the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com