Impulse-type grouting method

A pulsed, grouting technology, applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve problems such as failure to achieve grouting effect, small diffusion radius of slurry, etc., to improve filling rate, low construction requirements, strong The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0017] Pulse type grouting method of the present invention: concrete steps are as follows:

[0018] a. Including arranging the grouting drilling at the design depth in the surrounding rock grouting area, and cleaning the water and residue in the hole;

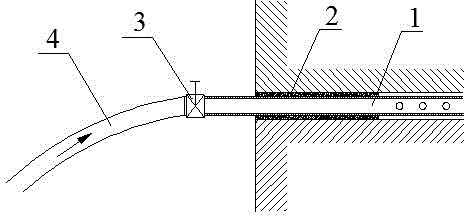

[0019] b. Insert a grouting pipe 1 equal to the depth of the drilled hole into the constructed grouting borehole, the inner end of the grouting pipe 1 contacts the bottom of the hole, the outer end is connected with the grouting hose 4 through the control valve 3, and the hole is sealed with conventional Cement 2 is used for sealing;

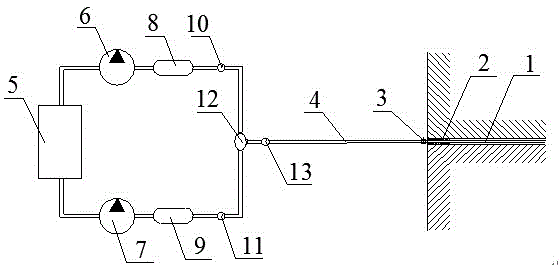

[0020] c. Connect the pulse grouting system on the grouting hose 4, and set the flow meter 13 at the outlet of the pulse grouting system; the pulse grouting system includes a reversing valve 12, which is respectively connected to The high-pressure liquid outlet circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com