High-strength composite grouting reinforcement material with island structure and preparation method thereof

A composite grouting and reinforcement material technology, which is applied in the field of engineering grouting reinforcement, can solve the problems of high viscosity of graphite system, low heat storage temperature, and low compressive strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

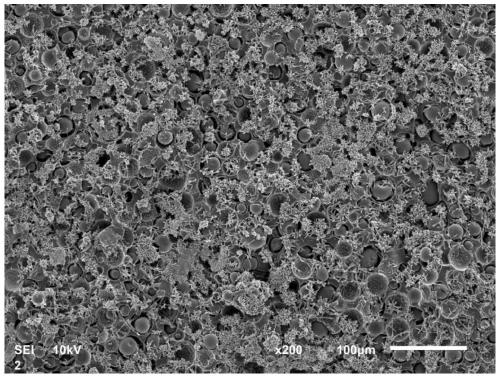

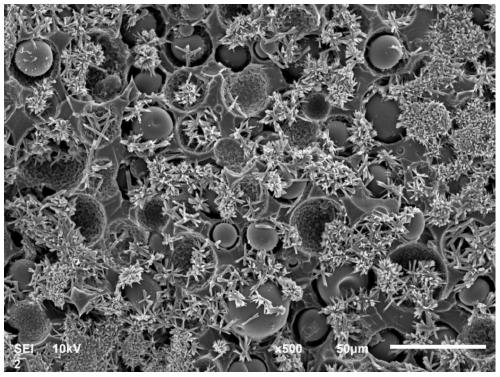

[0038] According to the parts by weight in Table 1, a high-strength composite grouting reinforcement material with a sea-island structure is prepared, wherein the SEM image of the material A prepared in Example 1 is as follows figure 1 (200x magnification) and figure 2 (500 times magnification), it can be clearly seen from the SEM image that material A has a sea-island structure.

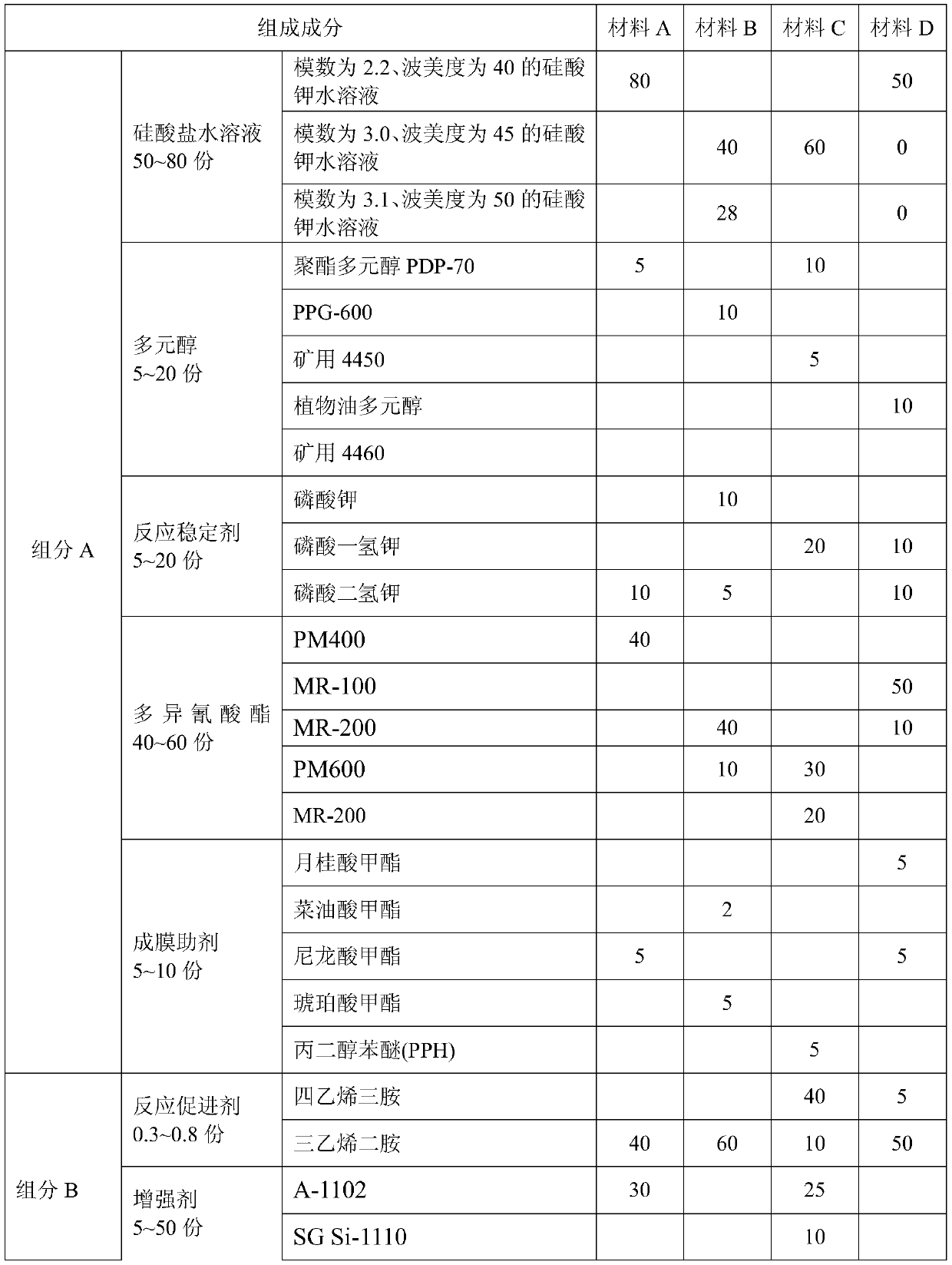

[0039] Table 1 Composition of different materials

[0040]

[0041]

[0042] The specific preparation method is:

[0043] (1) Preparation of component A: According to parts by weight, take silicate aqueous solution, polyisocyanate, polyol, reaction stabilizer, and film-forming aid, add it to the reaction kettle and oscillate with microwave for 30 minutes, and then put it into a water bath at 100°C Stir and heat at a medium constant temperature for 2 hours to obtain component A, which is sealed and packaged for use;

[0044] (2) Preparation of component B: according to parts by weight, take...

Embodiment 2

[0047] The strength, compressibility, stability, safety, viscosity, permeability, and diffusion radius of the material prepared in Test Example 1 are shown in Table 2.

[0048] Table 2 Performance comparison of different grouting reinforcement materials

[0049]

[0050]From the performance comparison of the test in Table 2, it can be seen that the high-strength composite grouting reinforcement material with sea-island structure prepared by the present invention has high strength characteristics, excellent compression performance (compressive strength above 65MPa), good stability , high safety (self-extinguishing within 1s), and low viscosity (the viscosity of component A is below 300mpa.s, the viscosity of component B is below 200mpa.s), strong penetration ability, large diffusion radius ( The diffusion radius is greater than 4m), which can be applied to coal mine roof and floor reinforcement, roadway reinforcement, slope reinforcement, soft soil foundation reinforcement a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com