Construction method for covering layer closed porthole high-pressure curtain grouting

A technology of hole sealing and curtain grouting, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problems of difficult implementation and high cost, and achieve the goal of solving the difficulty of hole formation, improving construction efficiency, and increasing drilling speed and hole formation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

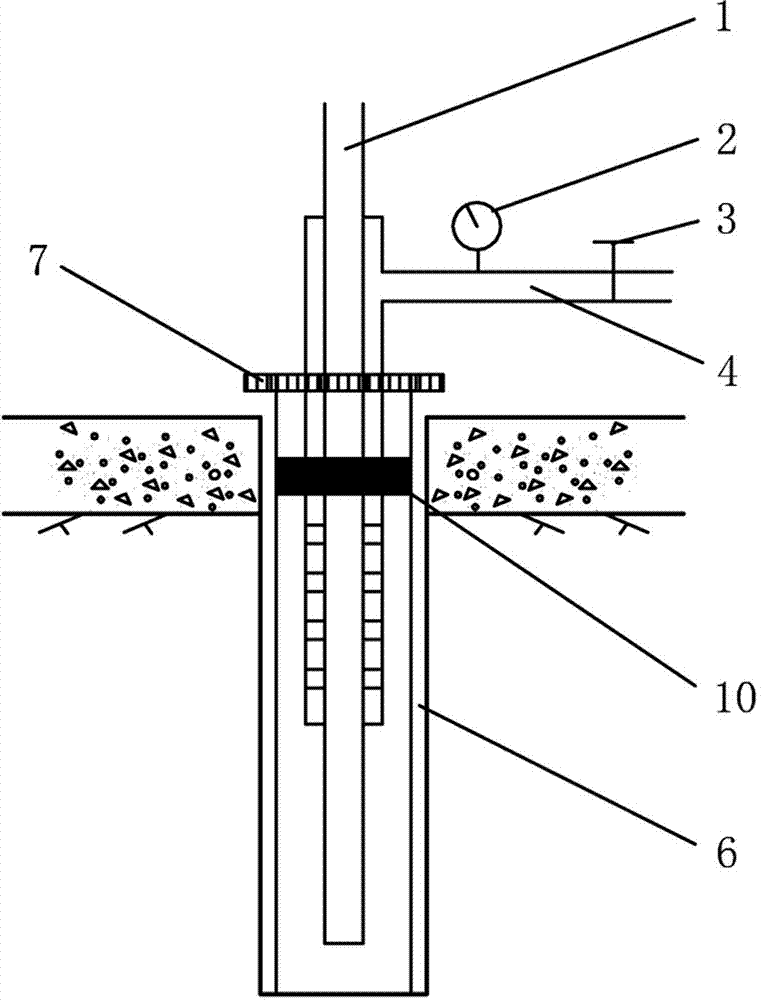

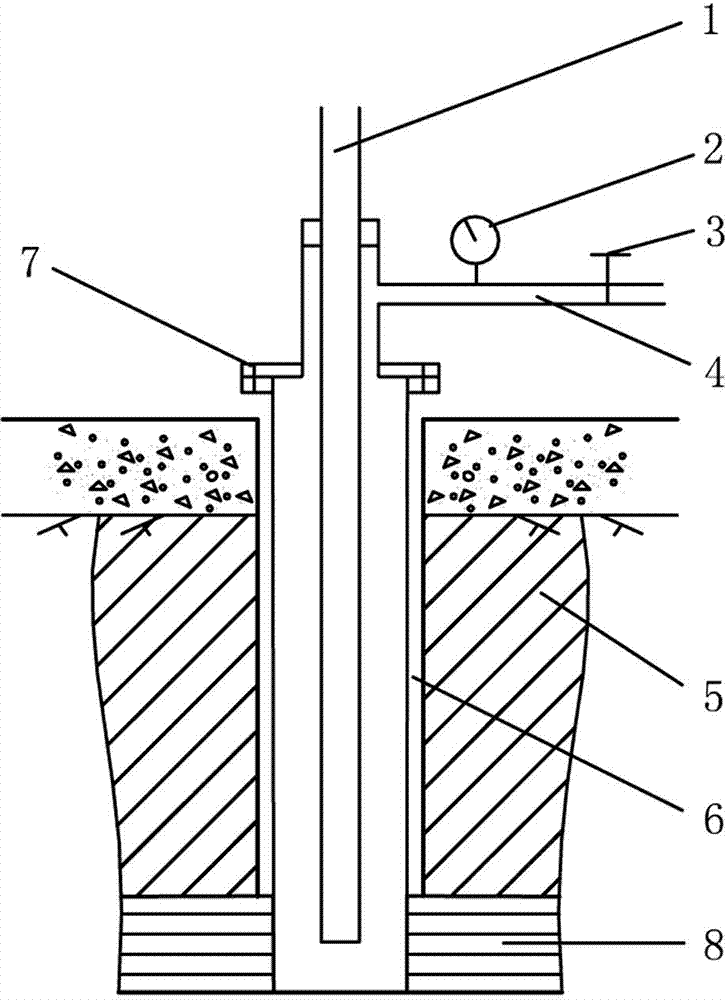

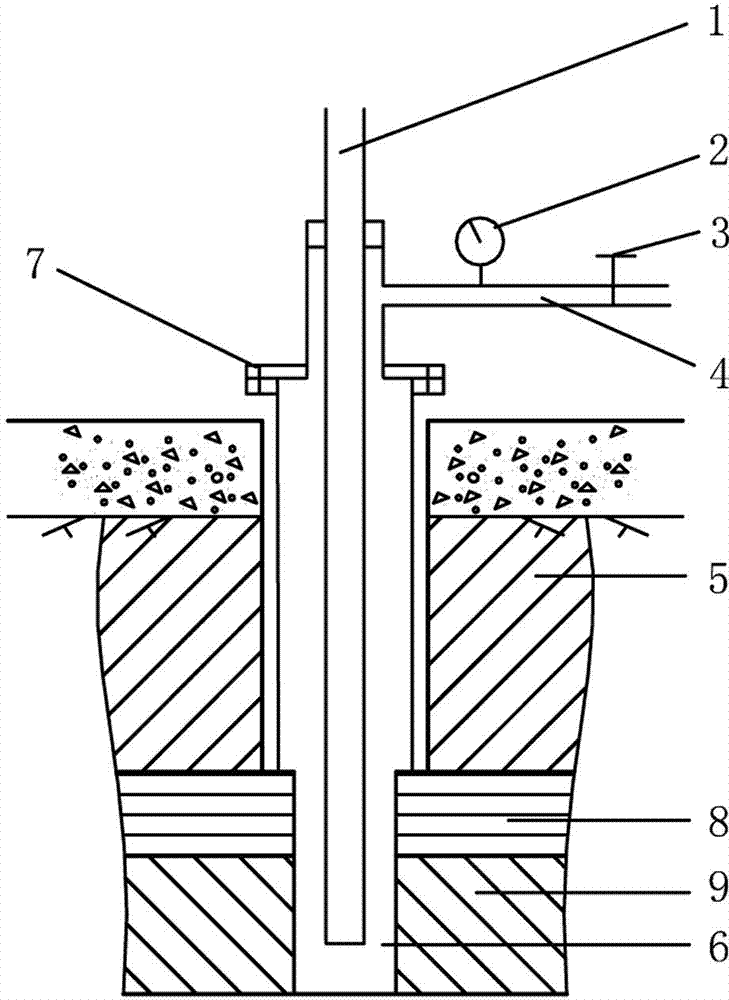

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] see Figure 1-3 , a kind of covering layer orifice sealing high-pressure curtain grouting construction method is characterized in that it comprises the following steps:

[0033] (1) Construction of non-grouting section

[0034] When constructing with a follow-up drilling rig, a casing with the same diameter is configured to follow up, and high-pressure wind is used as power, and the rock powder is rushed out of the hole by the residual wind in the hole, and the hole is formed by the casing wall that follows up.

[0035] When drilling with a core drilling rig, configure a diamond drill bit, use mud as a flushing fluid, and use a casing wall to form a hole. In order to avoid in-hole accidents such as drill sticking and hole collapse, drilling with small drilling pressure (2-3kN), low speed (300-400r / min), and large pump volume (50-60L / min) of flus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com