Technical method for extracting coal bed methane from constructed coal development area

A process method and technology in the development area, which are applied in the fields of mining fluids, mining equipment, and earth-moving drilling, etc., can solve the problems of easy-to-collapse holes, unsatisfactory changes in tectonic coal permeability, and limited change ranges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

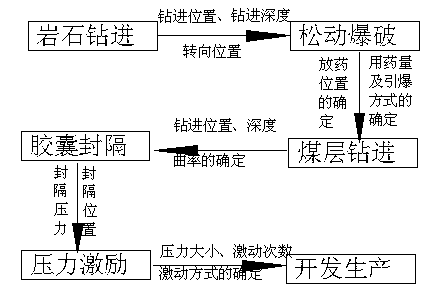

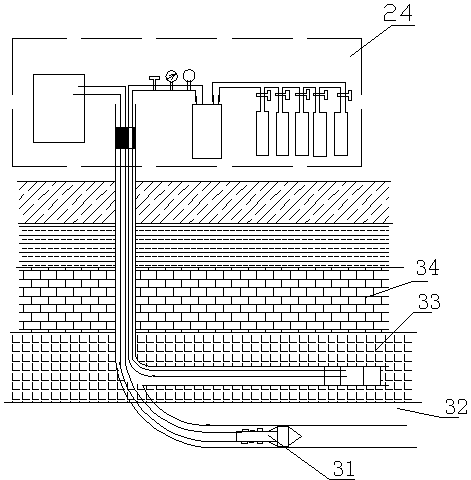

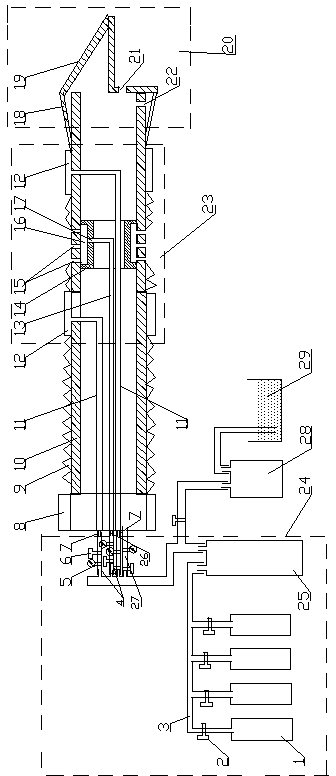

[0022] Depend on Figure 1-Figure 3 A method for extracting coalbed methane in a tectonic coal development area includes the following steps:

[0023] (1) Drill a vertical well from the ground to the rock formation drilling place. The vertical well will first pass through the overlying rock layer 34 from the ground and then reach the roof rock layer 33. The roof rock layer 33 is the rock layer area to be drilled, which is located above the coal seam roof , the rock formation is drilled within the range of 5-20m above the roof of the coal seam to be mined, and the rock formation to be drilled is relatively hard, and the thickness of the rock formation is ≥ 4.5m; (the rock formation is drilled at 5-20m above the roof of the coal seam to be mined Within the scope, the thickness of the rock strata is more than or equal to 4.5m, which is the best condition for the coalbed methane extraction process in the tectonic coal development area of the present invention. If this condition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com