Grouting reinforcement material applied to rapid repair of pavement structure, and preparation method and application

A technology of grouting reinforcement and pavement structure, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems of early mechanical performance of unseen polymers, incomplete performance of material properties, etc., to achieve environmental protection, easy operation, The effect of strong penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

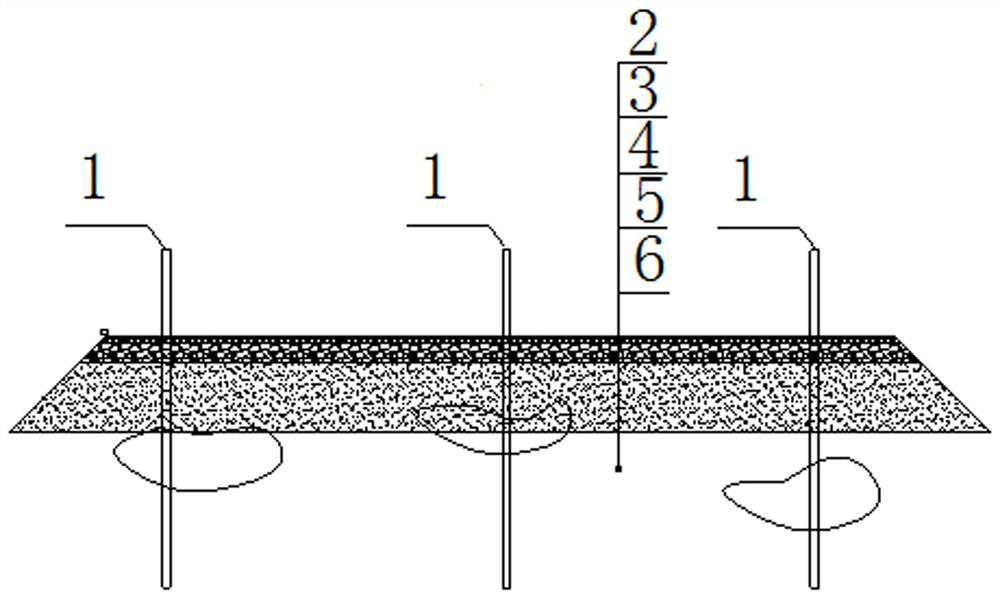

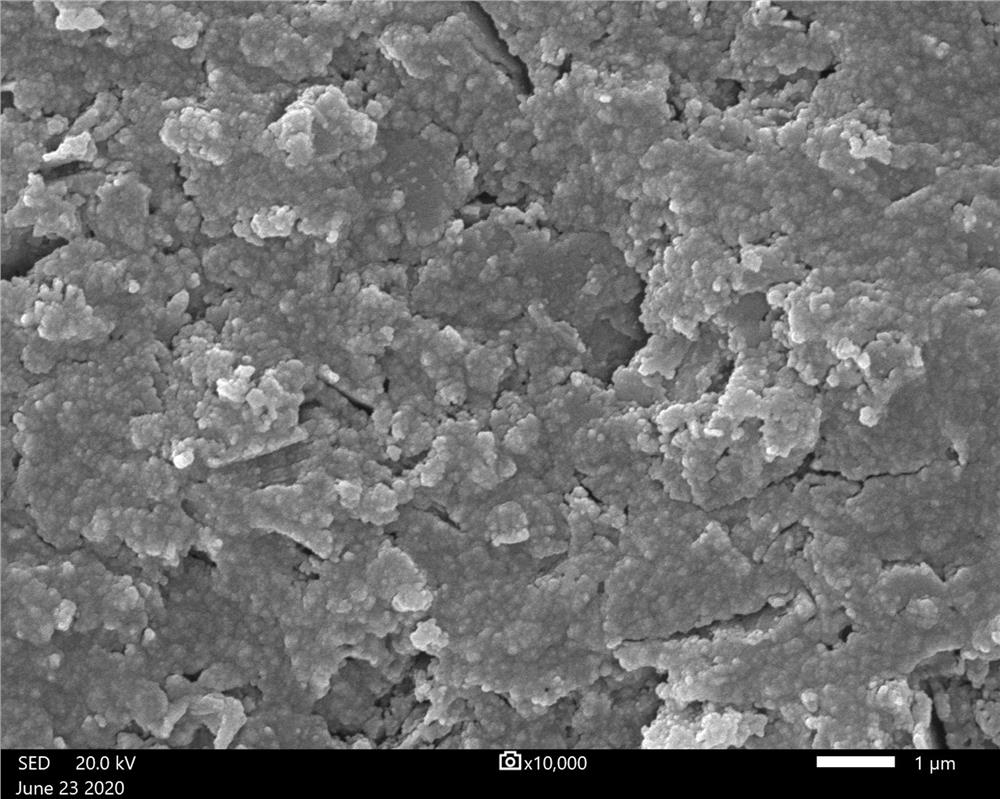

[0038] A grouting reinforcement material for rapid repair of pavement structure, the grouting reinforcement material includes geopolymer slurry, and the mass ratio formula of geopolymer slurry includes A component and B component, A component and B component Equal mass ratio mixing, the A component includes sodium silicate solution 31.5%, sodium hydroxide 4.2%, water 10.9%, amorphous nano-silicon dioxide 1.0%; B component includes metakaolin 20.9%, cement 14%, Slag 17.5%.

[0039] More specifically, the cement is superfine grouting cement with a specific surface area greater than 1200m 2 / kg. The slag is high-calcium slag with S95 grade, and the specific surface area is greater than 1200m 2 / kg. Metakaolin particle size specific surface area is greater than 1200m 2 / g. Amorphous nano silica, specific surface area greater than 1200m 2 / g. The Baume degree of sodium silicate solution is 38°.

Embodiment 2

[0041] A grouting reinforcement material for rapid repair of highway pavement structure, the grouting reinforcement material includes geopolymer slurry, and the mass ratio formula of geopolymer slurry includes A component and B component, A component and B group Mixing in equal mass ratios, the A component includes 35.5% of sodium silicate solution, 6.2% of sodium hydroxide, 14.9% of water, 2% of amorphous nano-silicon dioxide; B component includes 16.9% of metakaolin, 11% of cement , slag 13.5%.

[0042] More specifically, the cement is superfine grouting cement with a specific surface area greater than 1200m 2 / kg. The slag is high-calcium slag with S95 grade, and the specific surface area is greater than 1200m 2 / kg. Metakaolin particle size specific surface area is greater than 1200m 2 / g. The specific surface area of amorphous nano-silica is greater than 1200m 2 / g. The Baume degree of sodium silicate solution is 45°.

Embodiment 3

[0044] The grouting reinforcement material includes geopolymer slurry, the mass ratio formula of the geopolymer slurry includes component A and component B, and components A and B are mixed in equal mass ratios, and the component A includes sodium silicate Solution 33.5%, sodium hydroxide 5.2%, water 12.9%, amorphous nano-silica 1.5%; B component includes metakaolin 18.9%, cement 12.5%, slag 15.5%. More specifically, the parts by weight of each component in the geopolymer slurry are, component A (34.17 parts by weight of sodium silicate solution, 5.304 parts by weight of sodium hydroxide, 13.158 parts by weight of water, 1.53 parts by weight of amorphous nano silicon dioxide parts) and B component (slag 15.81 parts by weight, metakaolin 19.278 parts by weight, cement 12.75 parts by weight).

[0045] More specifically, the cement is superfine grouting cement with a specific surface area greater than 1200m 2 / kg. The slag is high-calcium slag with S95 grade, and the specific s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com