Coal and rock mass deep hole subsection grouting reinforcement device and reinforcement method

A technology of segmented grouting and reinforcement device, which is applied in vertical shaft equipment, earth-moving drilling, wellbore lining, etc., can solve the problems of serious slurry running, uneven slurry diffusion, and few types of grouting materials, so as to avoid slurry return. problems, improve the quality of grouting, and expand the effect of the effective diffusion radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

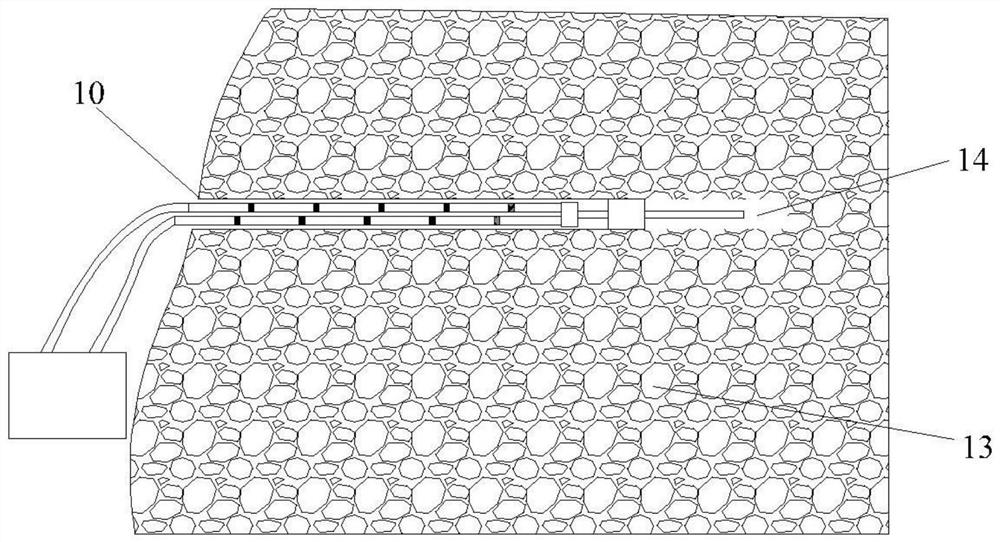

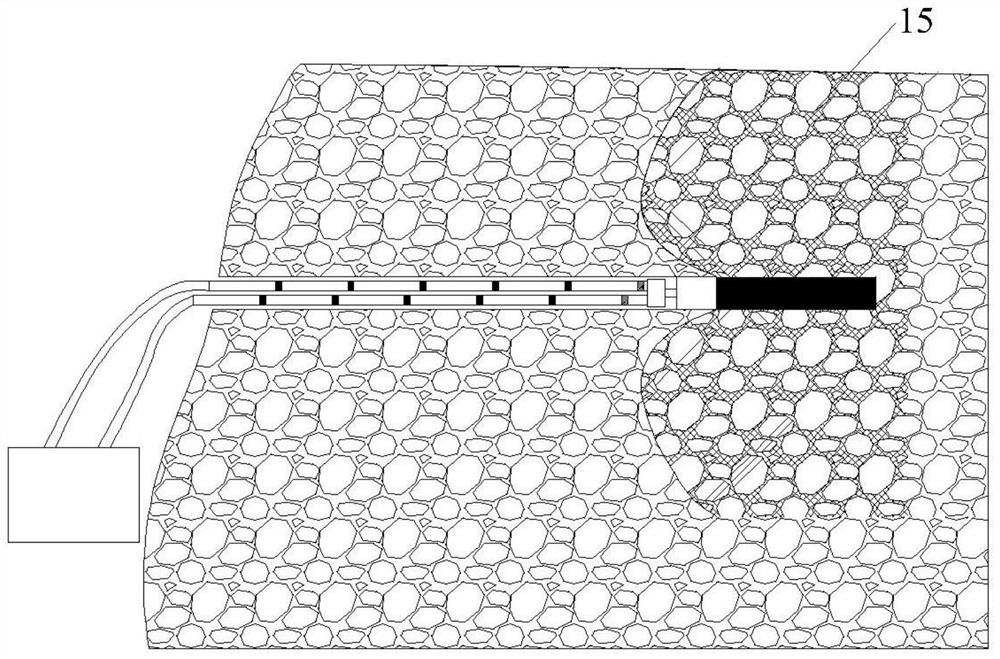

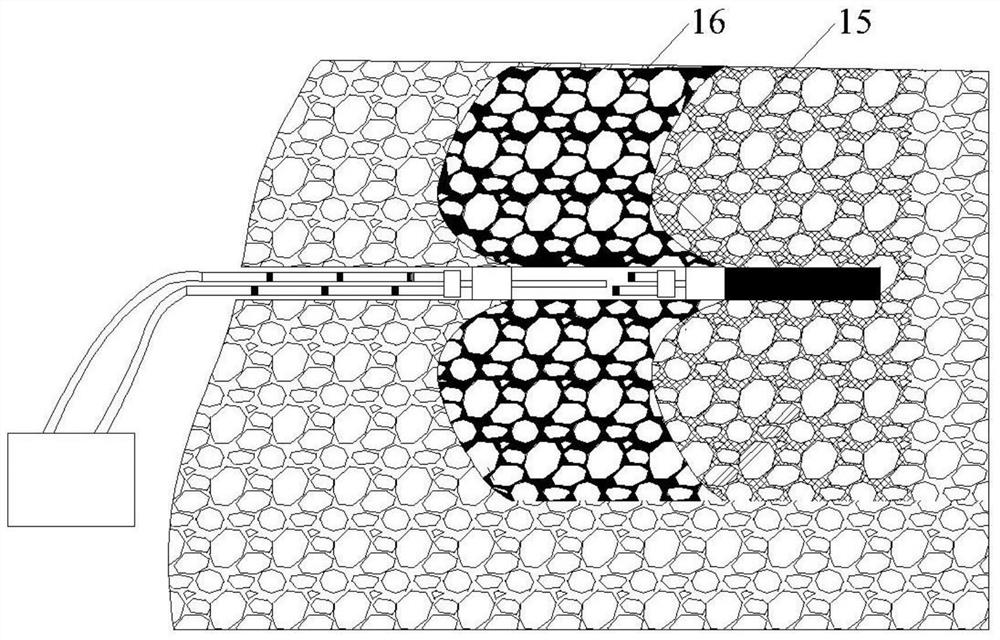

[0035] figure 1 Schematic diagram of the grouting reinforcement device installed in the grouting hole; figure 2 Schematic diagram of the completed structure for the first stage of grouting; image 3 Schematic diagram of the completed structure for the second stage grouting; Figure 4 It is a schematic diagram of the structure of the grouting reinforcement device; Figure 5 It is a schematic diagram of the structure of the mixing device;

[0036] As shown in the figure: the deep hole segmental grouting reinforcement device for coal and rock mass in this embodiment includes a grouting device 1 and at least two groups of grouting pipeline assemblies, and the grouting device has a The grout outlets for conveying different materials are matched and connected to the inlet ends of the grouting pipe assemblies, the outlet ends of each grouting pipe assembly are connected to the grouting head, and the grouting pipe assembly can realize the grouting with its own axis rotation Head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com