End component of nitrogen injection pipeline of gob of mine

A goaf and pipe end technology, which is applied in the field of end components of nitrogen injection pipelines in goafs, can solve problems such as blockage of nitrogen injection pipelines in goafs, poor nitrogen injection effect, damage, etc. Space, easy to manufacture, and beneficial to the effect of nitrogen diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

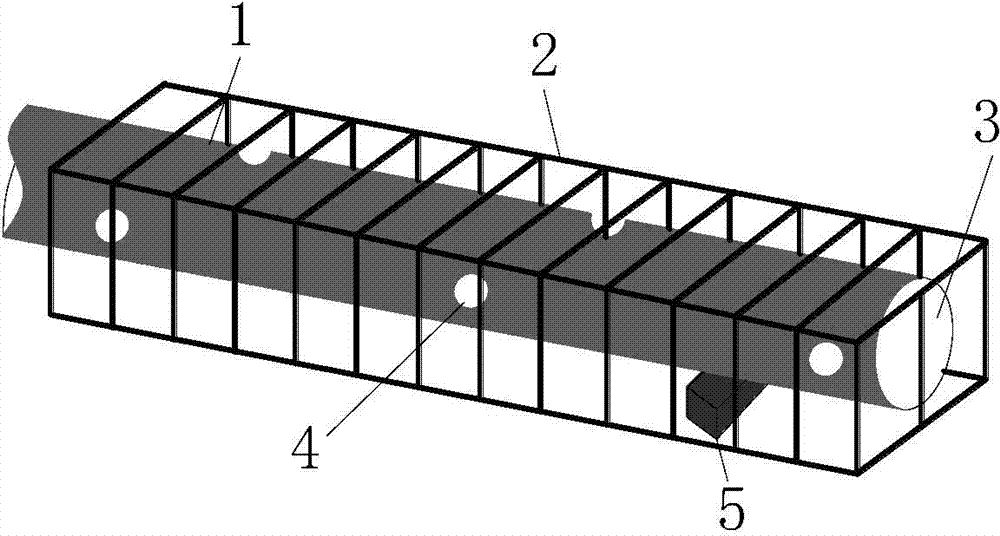

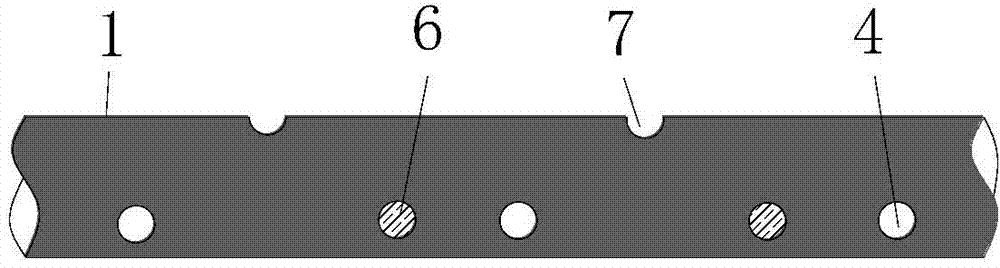

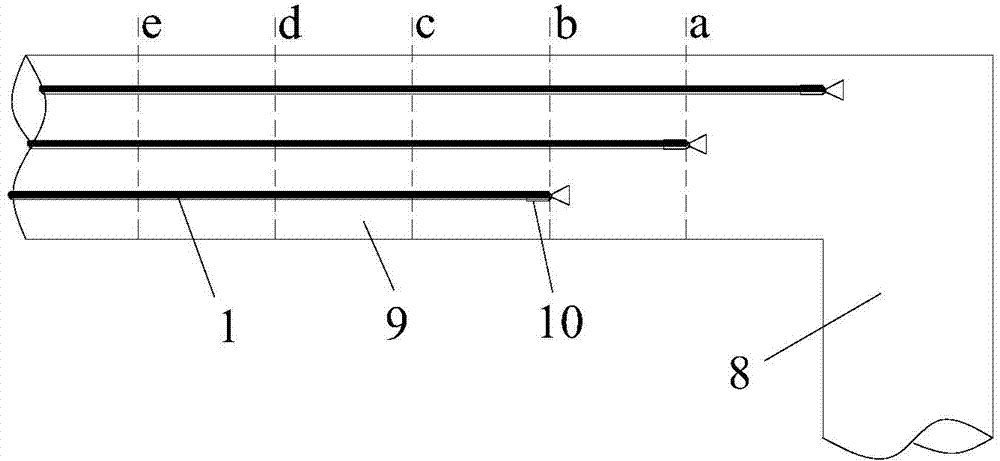

[0014] The end components of the nitrogen injection pipeline in the goaf of the mine, such as figure 1 , figure 2 As shown, it includes nitrogen injection pipe 1, steel cage 2, nitrogen injection pipe end 3, nitrogen injection pipe air outlet 4 and crossties 5. Spiral air outlet 4 is made on the length of 1m at the end of nitrogen injection pipe 1 to form nitrogen injection " "Flower tube", in which the hole diameter of the air outlet 4 is 20mm, the hole spacing is 0.2m, and the helix angle is 120°; the steel cage 2 is buckled on the flower tube section as a protective cover, which is 1.2m long, 0.25m wide, and 0.4m high, and the steel cage 2 They are 0.05m longer than both ends of the flower tube respectively; the nitrogen in the nitrogen injection pipe 1 escapes from the end 3 of the nitrogen injection pipe and the air hole 4 of the nitrogen injection pipe, and diffuses to the goaf; the crossties 5 lift the nitrogen injection pipe a certain distance from the ground.

[001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com