Shell valve side integrated hydraulic power-assisted recirculating ball steering gear assembly

A technology of hydraulic power assist and circulating ball, applied in mechanical steering gear, fluid steering mechanism, etc., can solve the problems of large shape and low energy efficiency per unit mass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

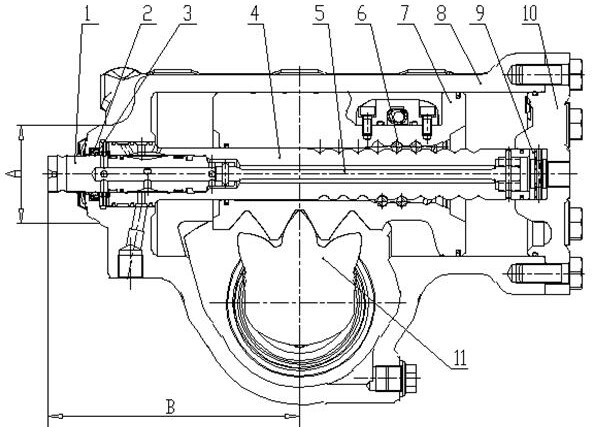

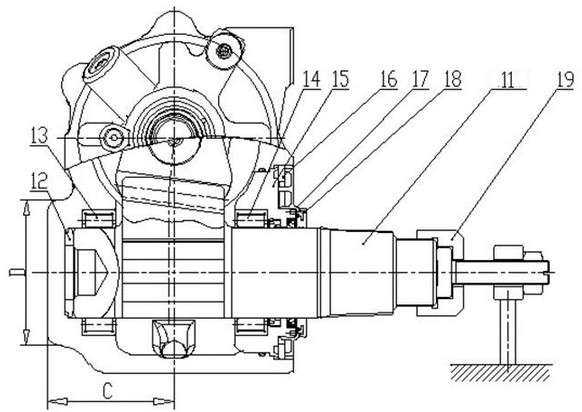

[0015] A hydraulic power-assisted recirculating ball steering assembly integrated on the shell valve side, including: input shaft assembly 1, oil seal 2, upper plane thrust bearing 3, steering screw assembly 4, torsion bar 5, steel ball flow 6, steering Nut assembly 7, shell assembly 8, lower plane thrust bearing 9, bottom cover assembly 10, arm shaft assembly 11, adjusting gasket 12, non-output end roller bearing 13, output end roller bearing 14, end Cover assembly 15, circlip 16 for holes, dust cover 17, dust cover 18, meshing gap adjustment tool 19; oil seal 2 is fixed in the inner hole of the upper end of housing assembly 8 for sealing to prevent external leakage. The housing assembly 8 integrates the housing, the valve body and the side cover. The upper end of the steering screw assembly 4 is fixed on the upper end of the main cylinder hole of the housing assembly 8 through the upper plane thrust bearing 3, and the lower end of the steering screw assembly 4 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com