Automobile clutch

A technology of clutch and clutch cover, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., to achieve the effect of high transmission efficiency, safe and reliable operation, and improved joint smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

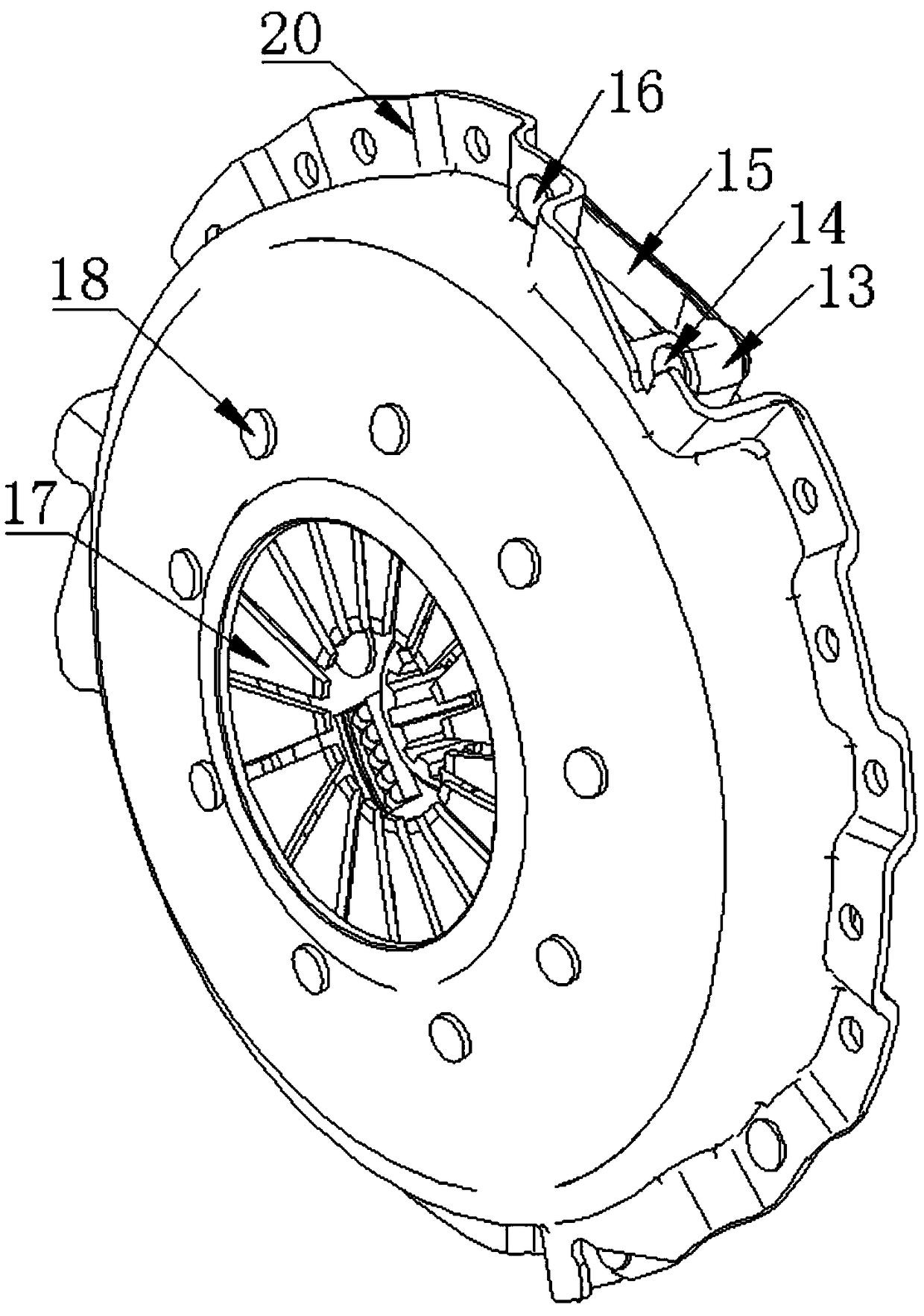

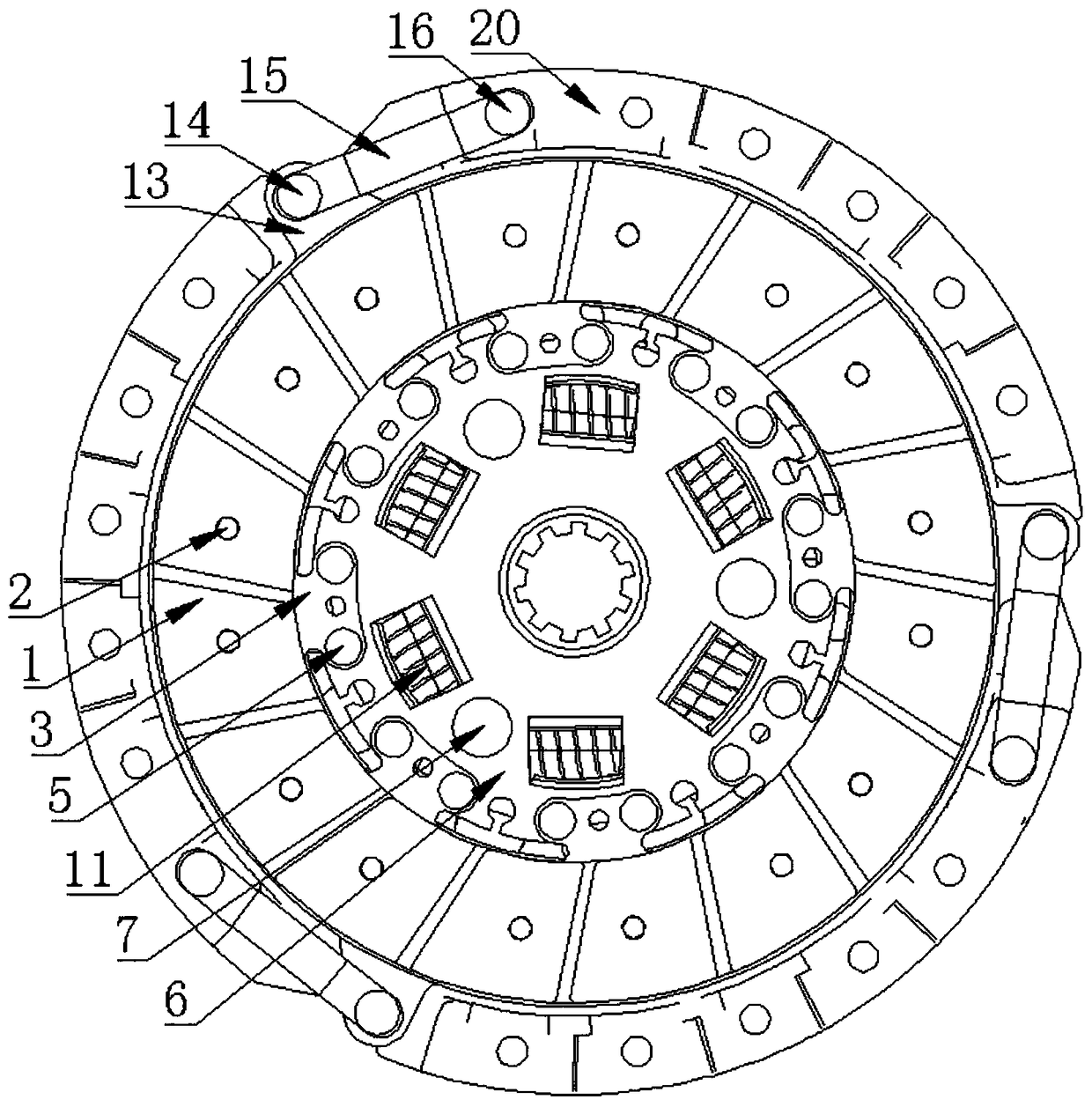

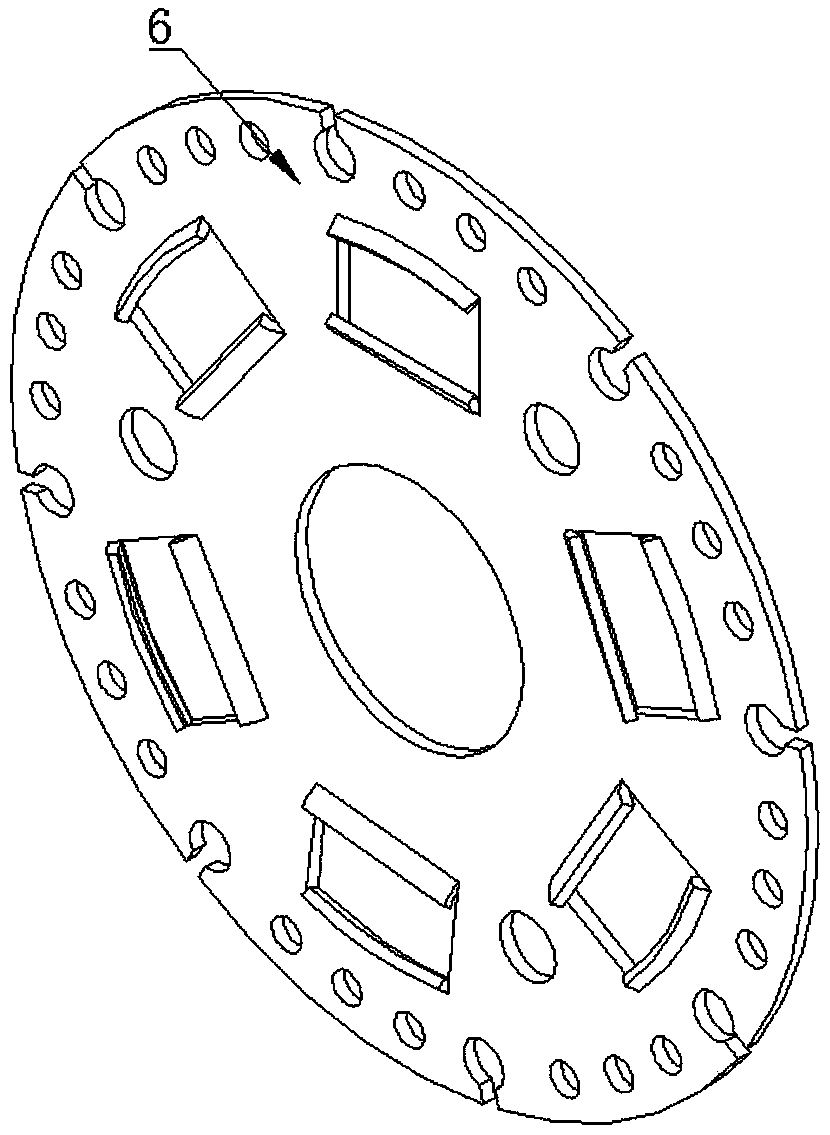

[0029] Such as Figure 1 to Figure 8 As shown, an automobile clutch includes a friction plate 1, a friction plate 2 4, and a connecting plate 3. The friction plate 1 and the friction plate 2 4 are symmetrically and coaxially distributed, and the connecting plate 3 is arranged on the friction plate. One 1 and the friction plate two 4 are connected by a rivet one 2, the connecting plate one 3 is connected with a transmission disk 6 through a rivet two 5, and the transmission disk 6 is connected with a damping disk 8 through a rivet three 7. The driven disk 6 and the damping disk 8 are arranged opposite to each other, and a driven disk hub 9 is provided therebetween. The center of the driven disk hub 9 is provided with a key groove, and the driven disk hub 9 is evenly distributed with rectangular shapes. The groove is provided with a spring 11 in the rectangular groove. A pressure plate 12 is arranged on the outer side of the friction plate 2 and the pressure plate 12 is evenly di...

Embodiment 2

[0034] Such as Figure 1 to Figure 8 As shown, an automobile clutch includes a friction plate 1, a friction plate 4, and a connecting plate 3. The friction plate 1 and the friction plate 2 4 are symmetrically and coaxially distributed, and the connecting plate 3 is arranged on the friction plate. One 1 and the friction plate two 4 are connected by a rivet one 2, the connecting plate one 3 is connected with a transmission disk 6 through a rivet two 5, and the transmission disk 6 is connected with a damping disk 8 through a rivet three 7. The driven disk 6 and the damping disk 8 are arranged opposite to each other, and a driven disk hub 9 is provided therebetween. The center of the driven disk hub 9 is provided with a key groove, and the driven disk hub 9 is evenly distributed with rectangular shapes. The groove is provided with a spring 11 in the rectangular groove. A pressure plate 12 is arranged on the outer side of the friction plate 2 and the pressure plate 12 is evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com