Pressure-resistant stamping mold for basic cover of easy-to-pull cover

A technology of stamping dies and easy-open lids, which is applied in the field of stamping molds for basic lids of easy-open lids, to achieve the effect of increasing the difficulty of processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

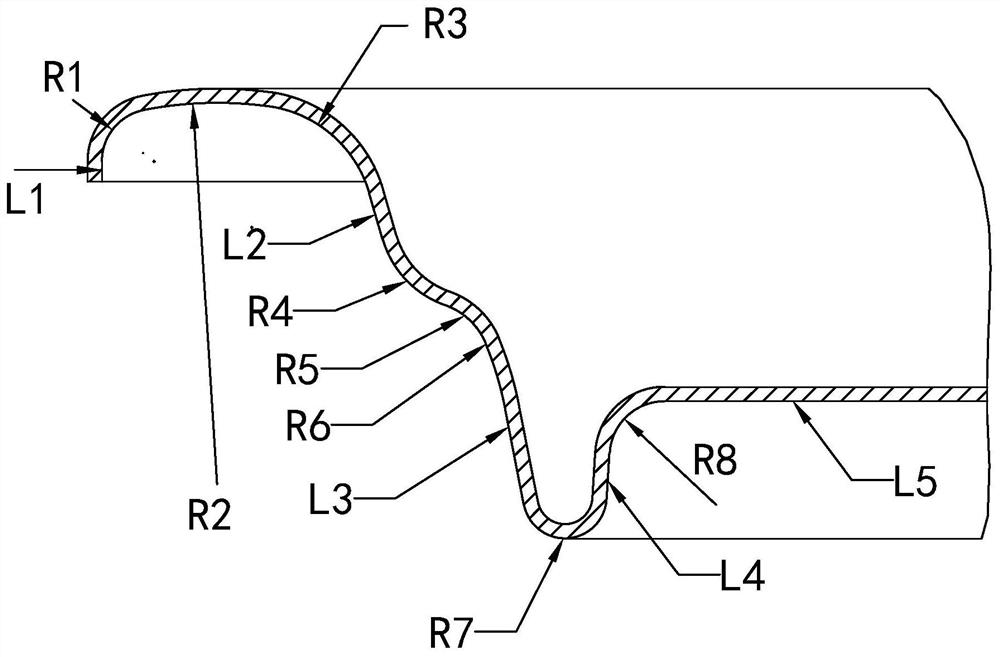

[0073] Embodiment 1: A stamping die for a basic cap of a pressure-resistant easy-open lid (no preformed stamping die)

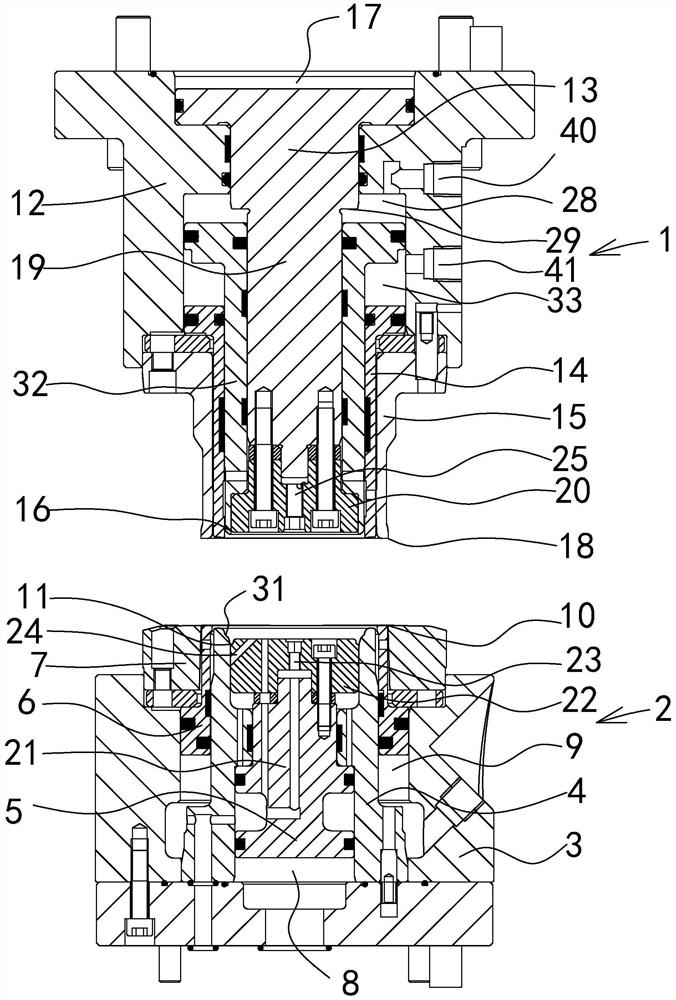

[0074] Such as Figure 1-3 As shown, the stamping die consists of two parts, the lower die 2 and the upper die 1 (see figure 2 ).

[0075] The lower mold 2 is mainly composed of a lower mold base 3, a lower mold core ring 4, a lower mold core 5, a lower binder ring 6 and a lower knife 7 (see figure 2 ), wherein: the lower mold base 3 is an open cylinder (see figure 2 ). The lower mold core ring 4 is an annular body, which is fixed in the opening of the lower mold base 3 by positioning pins and bolts, and is concentric with the lower mold base 3 (see figure 2 ). Described lower mold core 5 is made up of lower mold core seat 21 and lower mold core body 22 (see figure 2 ), the lower mold core seat 21 is fixedly connected with the lower mold core body 22, the action part of the lower mold core 5 is the lower mold core body 22, and the lower mold core b...

Embodiment 2

[0083] Embodiment 2: A kind of pressure-resistant type easy-open lid basic lid stamping die (with preformed stamping die)

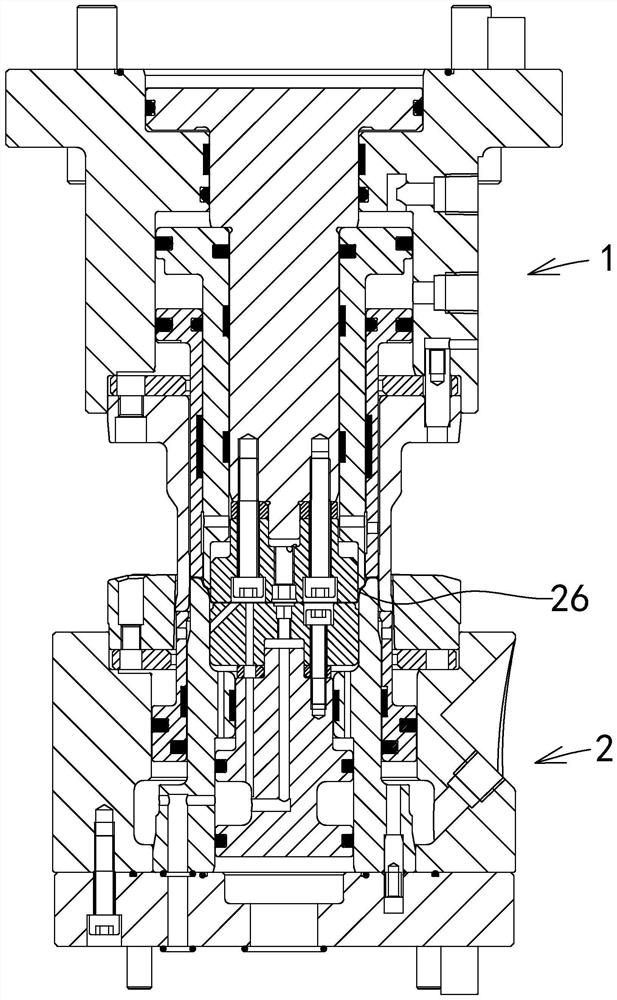

[0084] Such as Figure 16 As shown, the stamping die consists of two parts, the lower die 2 and the upper die 1 (see Figure 16 ).

[0085]The difference between embodiment 2 and embodiment 1 is that the bottom of the upper mold core body 20 is different, and the bottom of the upper mold core body 20 in embodiment 1 is a flat bottom, that is, the bottom of the upper mold core body 20 corresponds to the seventh basic cover. The parts of the arc segment R7, the fourth straight line segment L4 and the eighth arc segment R8 are suspended relative to the top of the lower mold core 22 under the mold clamping state. And the bottom of embodiment 2 upper mold core body 20 is provided with the R angle that protrudes downwards for the edge (see Figure 17 ), that is, the bottom of the upper mold core body 20 is provided with a contour corresponding to the eighth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com