LED chip for reducing light shield and improving luminous efficiency through extension electrode and its production technique

A technology of light-emitting diodes and light-emitting efficiency, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of power consumption, inability to be extracted, low-efficiency light-emitting diodes, etc., to avoid occlusion, improve current diffusion uniformity, and improve light output. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

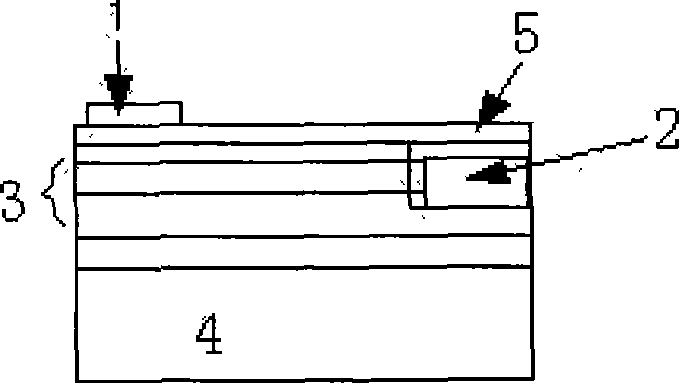

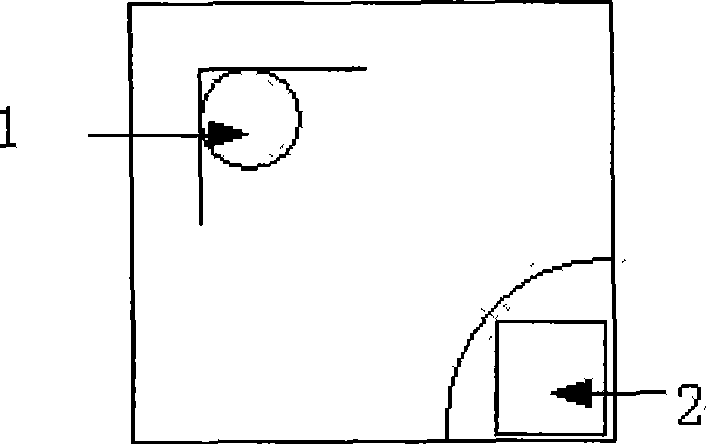

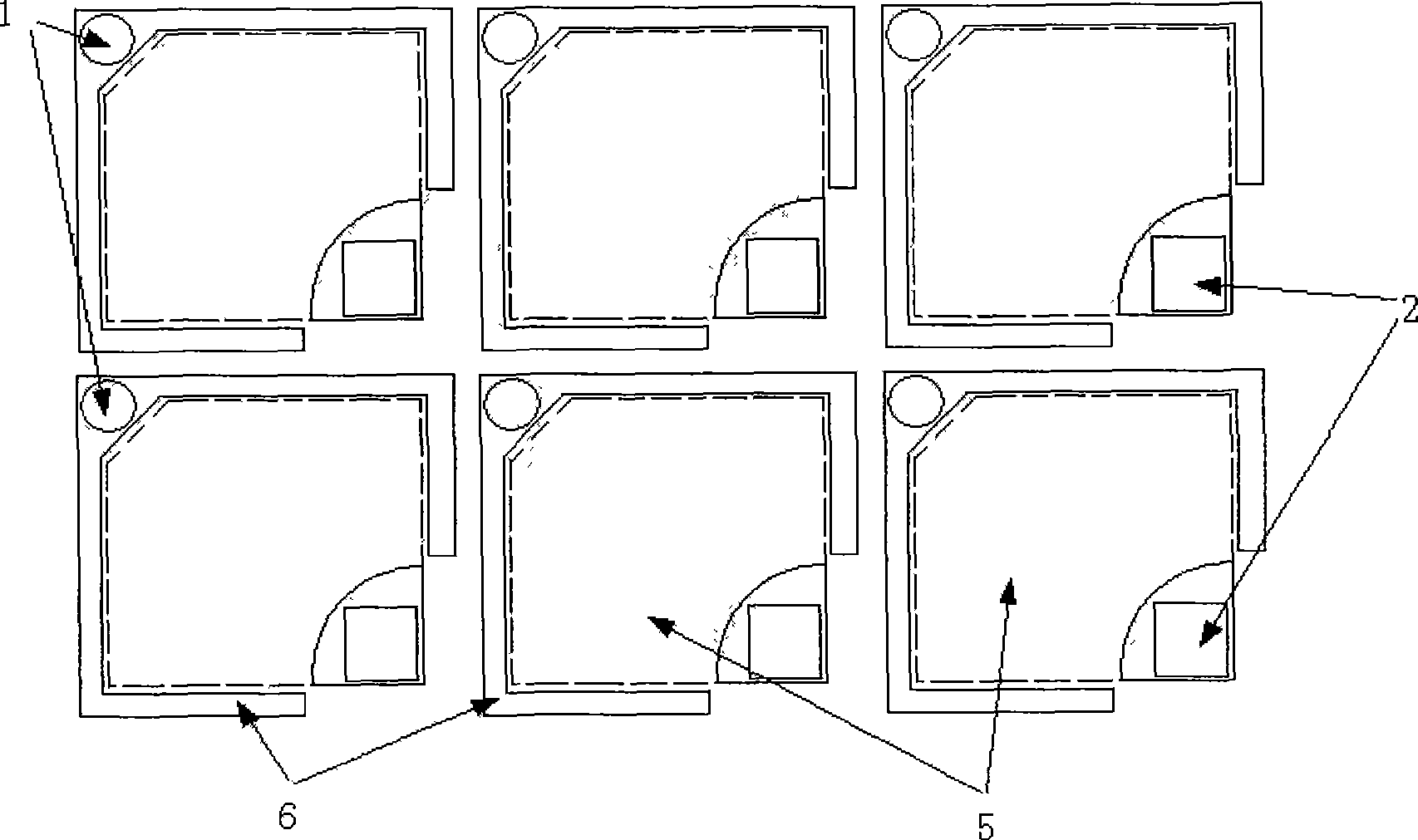

[0025] see image 3 , Figure 4 and Figure 5 , the light-emitting diode chip that reduces light-emitting shading and improves light-emitting efficiency by extending electrodes includes: p-type electrode pad 1, n-type electrode pad 2, light-emitting active layer 3, substrate 4, transparent current spreading layer 5, and auxiliary current spreading layer 6 1. The insulating layer 7 is characterized in that after the light-emitting active layer 3 is fabricated on the substrate 4 based on a conventional process, the light-emitting active layer 3 around each chip is etched away, and the n-type gold pad2 is etched out position, deposit an insulating layer 7 around the chip until it is flush with the light-emitting active layer 3, then grow a transparent current spreading layer 5, and make an n-type gold pad and a p-type gold pad after making an auxiliary curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com