Reactive grouting reinforcement material with low smoke toxicity and high mechanical strength and preparation method thereof

A technology of grouting reinforcement and mechanical strength, which is applied in the field of grouting reinforcement materials, can solve problems such as poor permeability and toughness, high exothermic temperature, failure of rescue devices, etc., achieve strong penetration ability, low viscosity, and reduce preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

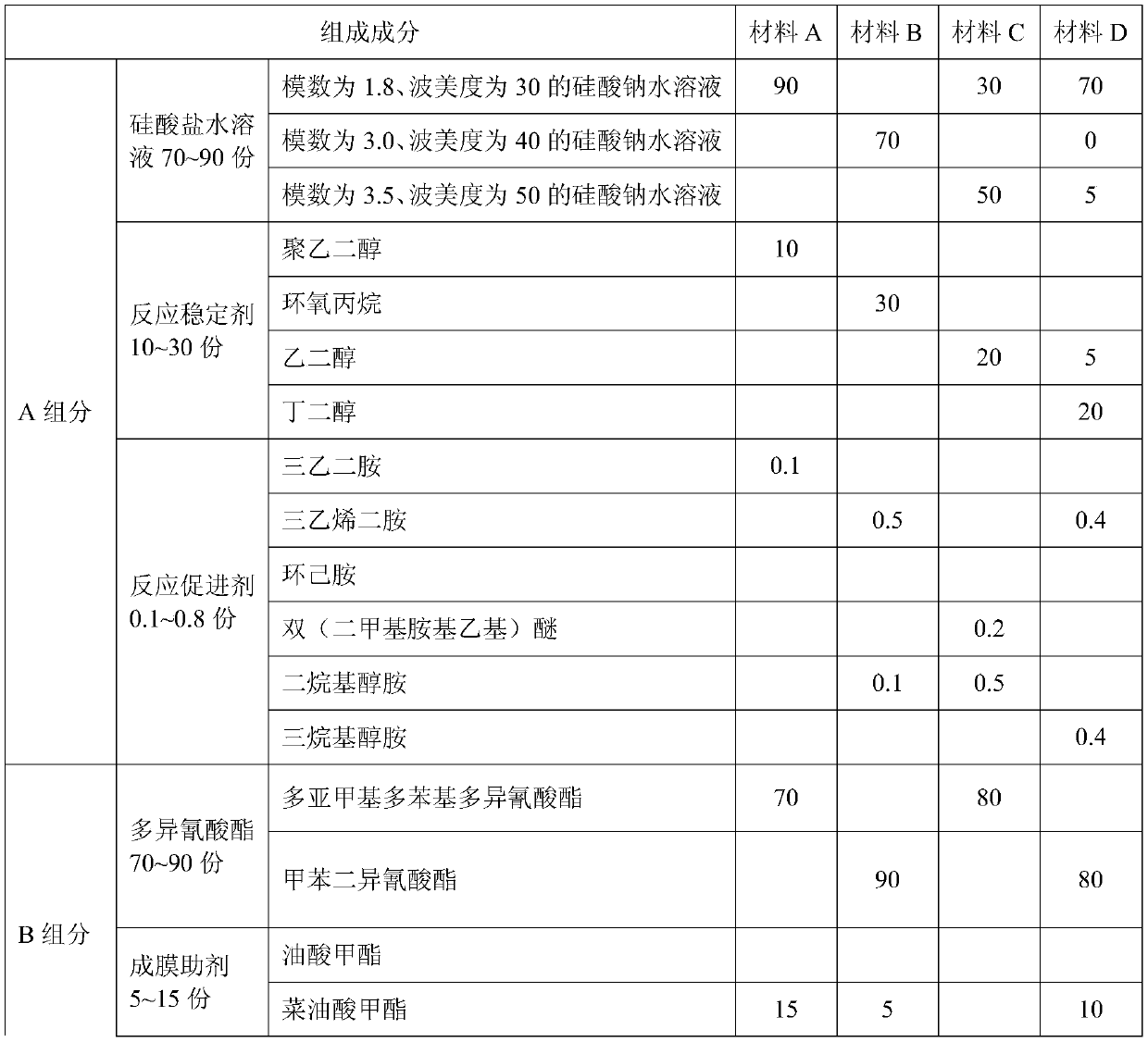

[0027] First prepare component A and component B according to the parts by weight in Table 1, and then mix and cure equal volumes of component A and component B to obtain a reactive type with low smoke toxicity and high mechanical strength Grout reinforcement material.

[0028] Table 1 Composition of different materials

[0029]

[0030]

[0031] The preparation method is:

[0032] (1) Preparation of component A: take a reaction stabilizer, a reaction accelerator and an aqueous silicate solution in parts by weight, stir to make them evenly mixed, and obtain component A, which is sealed and packaged for use;

[0033] (2) Preparation of component B: according to parts by weight, take polyisocyanate, film-forming aids and reinforcing agents and add them to the reaction kettle, stir to make them evenly mixed, and obtain component B, which is sealed and packaged for use;

[0034] (3) Curing: Mix the A component and the B component in the sealed package according to the equa...

Embodiment 2

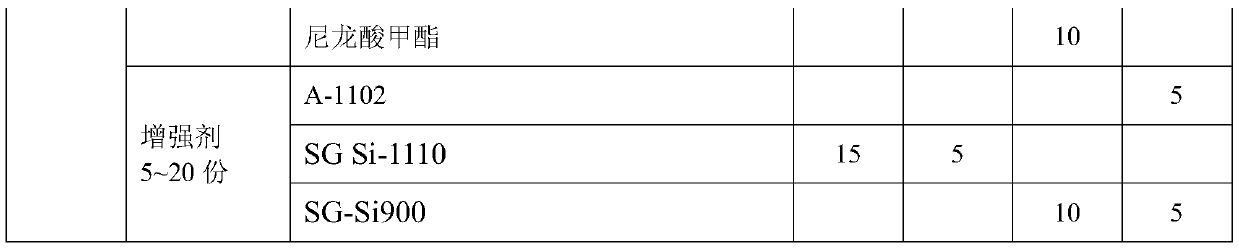

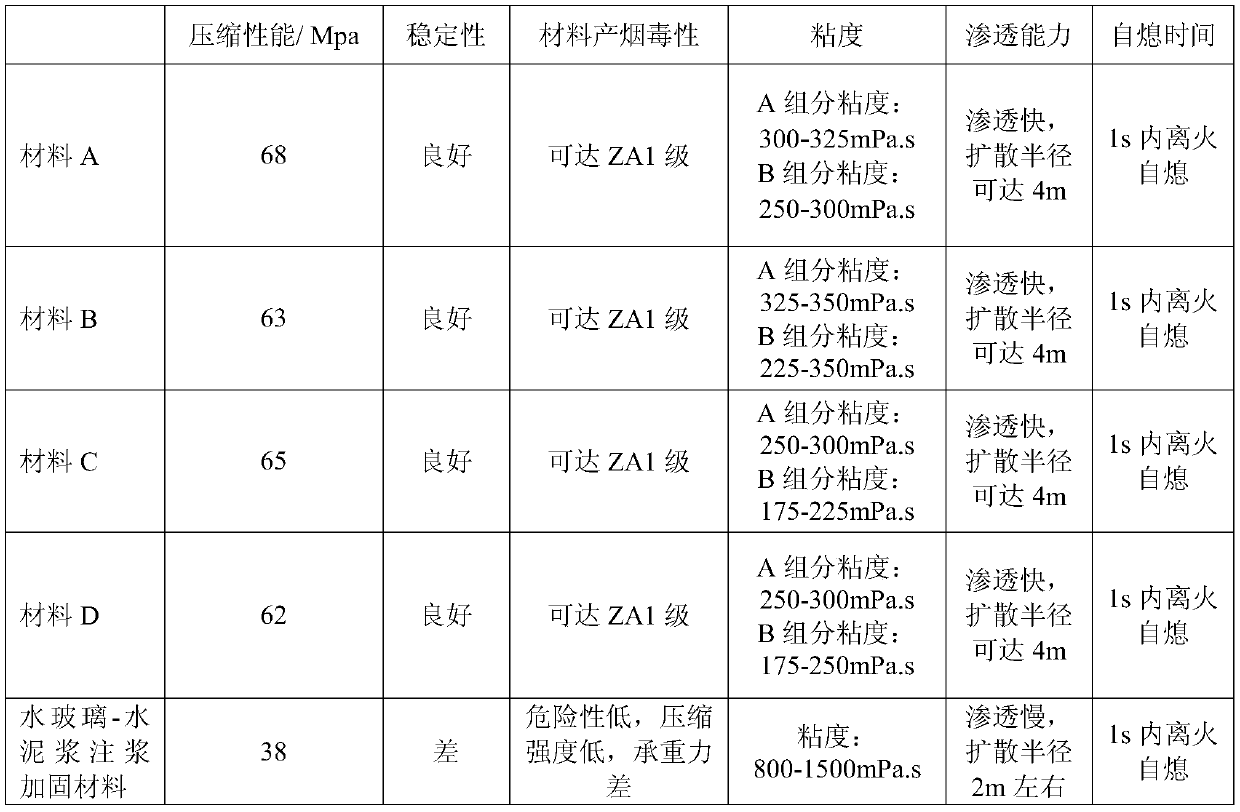

[0036] Compression performance, stability, safety, viscosity, permeability, diffusion radius of the material prepared in Test Example 1, and water glass-cement grouting reinforcement material, polyurethane grouting material and silicic acid in the prior art Salt-modified polyurethane grouting materials were compared, and the results are shown in Table 2.

[0037] Table 2 Performance comparison of different grouting reinforcement materials

[0038]

[0039]

[0040] It can be seen from the performance in Table 2 that the reactive grouting reinforcement material prepared by the present invention has excellent compression performance (up to 60Mpa or more), good stability (both stability is good), high safety (material smoke toxicity It can reach ZA1 level, self-extinguishing after leaving the fire within 1s), and also has the characteristics of low viscosity (viscosity of component A and component B are both below 325mPa.s), strong penetration ability, and large diffusion r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com