Variable-diameter multi-direction anchor pile

A variable-diameter, weak technology, applied in sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of weak rock and soil strength and integrity improvement, difficult to control the enhancement effect, and limited application range, etc. Achieve the effect of wide applicability, convenient construction and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

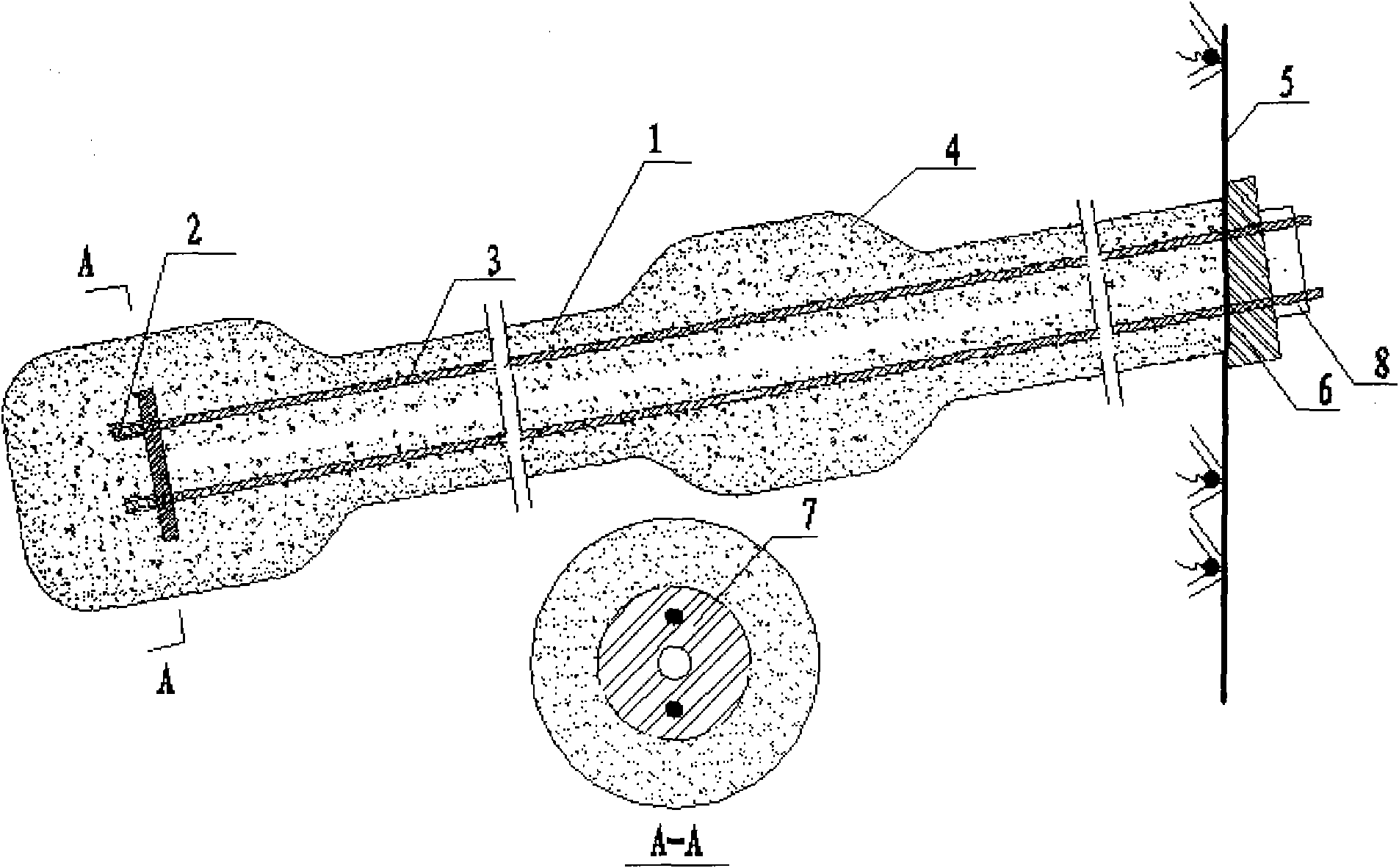

Image

Examples

Embodiment Construction

[0016] (1) Forming method of variable-diameter oblique piles with rapid anchorage of rock and soil

[0017] (1) Determine the drilling method according to the direction required by the design (horizontal, oblique or vertical);

[0018] (2) Breaking soft rock and soil by means of rotary cutting;

[0019] (3) The gel is injected through the drill pipe, and the gel can be: cement slurry, lime slurry, chemical gelling agent, cement mortar, etc.;

[0020] (4) Inject the gelled slurry through the nozzle on the drill bit;

[0021] (5) Inject while stirring;

[0022] (6) Change the injection pressure and the rotation speed and reciprocating time of the drill bit;

[0023] (7) The drill bit reciprocates until it reaches the designed pile length and pile diameter;

[0024] (2) Forming method of variable diameter anchor pile

[0025] By changing the injection pressure, the diameter of the injection port, the speed of rotation, advancement, and retreat, and the injection process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com