Novel steel wire rope clamp

A wire rope clip and wire rope technology, which is applied in the field of bundling reinforcement and new wire rope clips, can solve the problems of increased transportation costs and waste, and achieve the effects of simple structure, improved efficiency, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

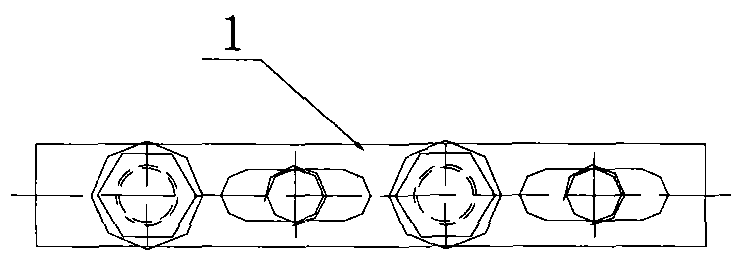

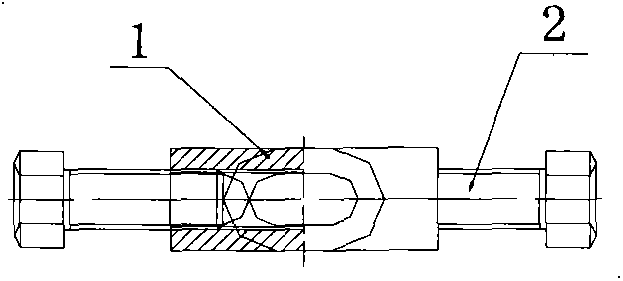

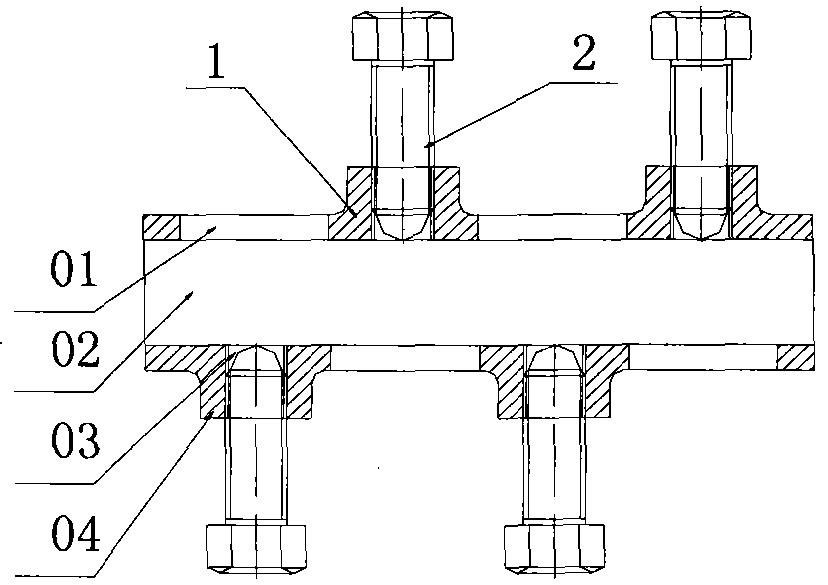

[0020] exist figure 1 , figure 2 middle image 3 Among them, the new-style steel wire rope clamp used for lap joint fixing is formed by connecting the rope ferrule (1) and the tightening bolt (2). The rope ferrule (1) is made of precision casting; the rope ferrule (1) is Rectangular, the end surface is oblate, and the inside is a flat circular long through hole. There are four cylindrical bosses (04) on both sides of the rope ferrule, which are evenly distributed on both sides of the rope ferrule. The inside is a threaded hole (03). The opposite side of the threaded hole of each cylindrical boss is a strip hole (01), and each threaded hole is respectively screwed into a jacking bolt (2).

[0021] exist Figure 4 Among them, the new type of wire rope clamp used for fixing the end is connected by a rope ferrule (1) and a tightening bolt (2). The rope ferrule (1) is rectangular, and there are three cylindrical bosses on both sides of the rope ferrule (04), evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com