Manufacturing method and special needling equipment for collagen fiber regenerated bark

A technology of collagen fiber and manufacturing method, which is applied in the field of manufacturing method of collagen fiber regenerated leather and its special acupuncture equipment, and can solve the problem that the non-woven needle punching process is not suitable for collagen fiber, the strength of the fiber web is not improved, and the fiber web is scratched And other problems, to achieve the effect of high reinforcement efficiency, stable performance, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

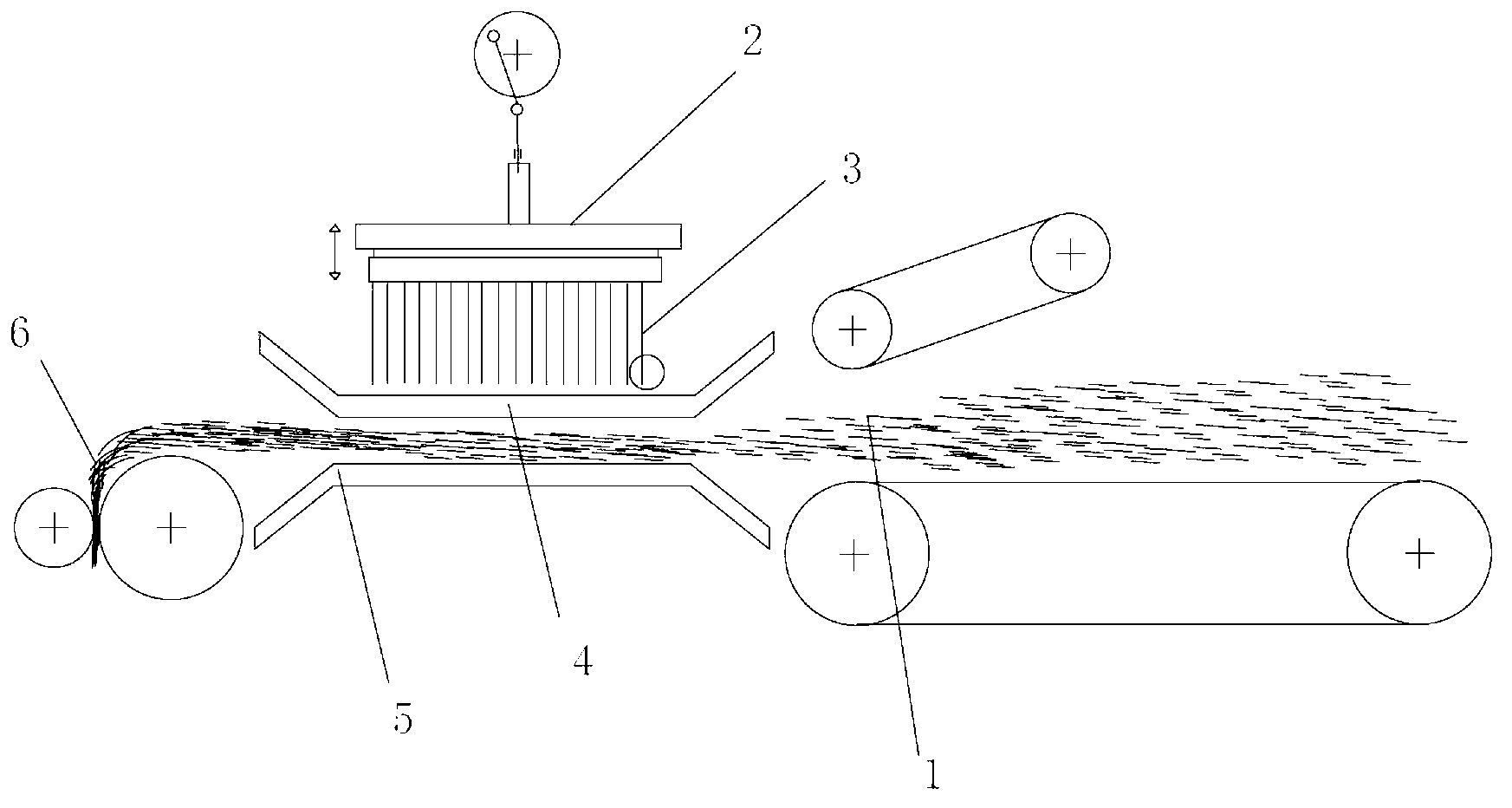

[0034] A kind of manufacture method of collagen fiber regenerated skin, its technological process comprises the following steps in sequence:

[0035] (1) Defibrilation: Extract collagen fibers from pig, sheep, and cowhide dermis, and obtain collagen fibers with an average length of 1-3 cm. Among them, pig, sheep, and cowhide are raw animal hides or scraps from tanning.

[0036] (2) Laying: Use a carding and laminating machine to evenly spread the obtained collagen fibers into a fiber web with a gram weight of 100-350 g / m2 at a speed of 30-35 m / min.

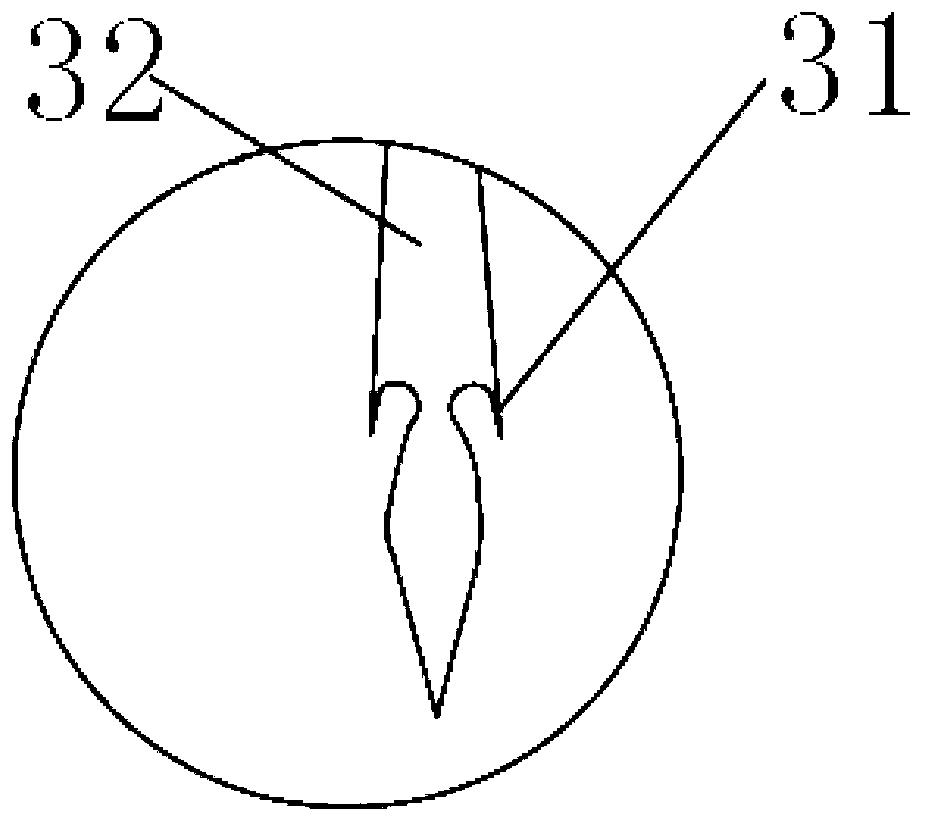

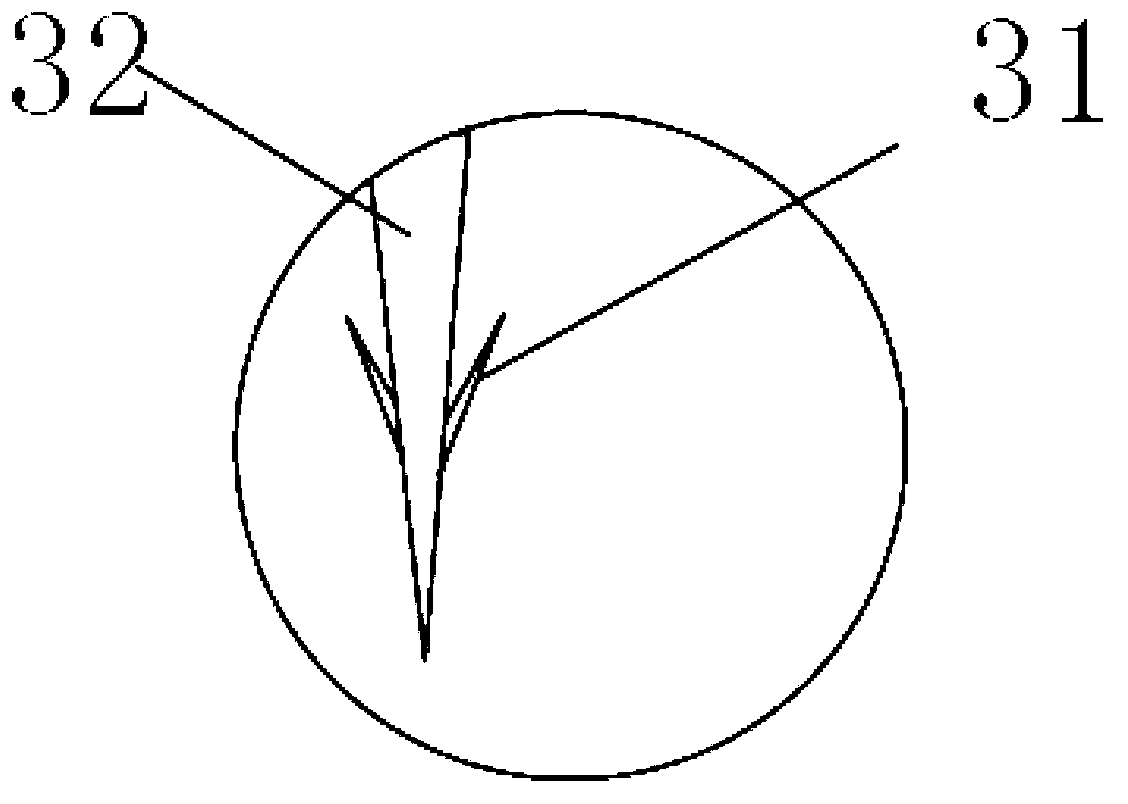

[0037] (3) Acupuncture: The laid fiber web is punctured front and back through a special needling machine to form a base fabric, and the needling density is 50-200 needles / square meter; among them, each needle of the special needling machine There are 1~3 barbs on it, and the angle between the barbs and the needle handle of the needle is 5~32°.

[0038] (4) Edge trimming, rolling, and packaging: after trimming the irregular and r...

Embodiment 2

[0042] The present invention is a kind of manufacturing method of collagen fiber regenerated skin, and its technological process comprises the following steps in sequence:

[0043] (1) Defibrilation: Extract collagen fibers from pig, sheep, and cowhide dermis, and obtain collagen fibers with an average length of 1-3 cm. Among them, pig, sheep, and cowhide are raw animal hides or scraps from tanning.

[0044] (2) Laying: Use a carding and laying machine to evenly spread the obtained collagen fibers into a fiber net with a gram weight of 100-150 grams per square meter, and then use an air-laid machine to evenly spread the obtained collagen fibers into a gram weight of 200-100 grams per square meter. For 350 g / m2 fiber web, the laying speed of carding and air-laying is 30~35 m / min.

[0045] (3) Acupuncture: The laid fiber web is punctured front and back through a special acupuncture unit to form a base fabric, and the acupuncture density is 50-200 needles / square meter; among them...

Embodiment 3

[0051] The present invention is a kind of manufacturing method of collagen fiber regenerated skin, and its technological process comprises the following steps in sequence:

[0052] (1) Defibrilation: Extract collagen fibers from pig, sheep, and cowhide dermis, and obtain collagen fibers with an average length of 1-3 cm. Among them, pig, sheep, and cowhide are raw animal hides or scraps from tanning.

[0053] (2) Laying: Use an air-laid machine to evenly mix the obtained collagen fibers with hot-melt adhesive fibers and spread them into fiber webs with a gram weight of 100-350 g / m2 at a speed of 30-35 m / min.

[0054] (3) Acupuncture: The laid fiber web is punctured front and back through a special acupuncture unit to form a base fabric, and the acupuncture density is 50-200 needles / square meter; among them, the special acupuncture unit consists of 5 specially-made The acupuncture machine is composed of 1~3 barbs on each needle of the special acupuncture machine, and the angle b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com