Vertical crack grouting and reinforcing method of prestressed concrete hollow slab bridge bottom plate

A hollow slab bridge, longitudinal crack technology, used in bridge reinforcement, bridges, bridge materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

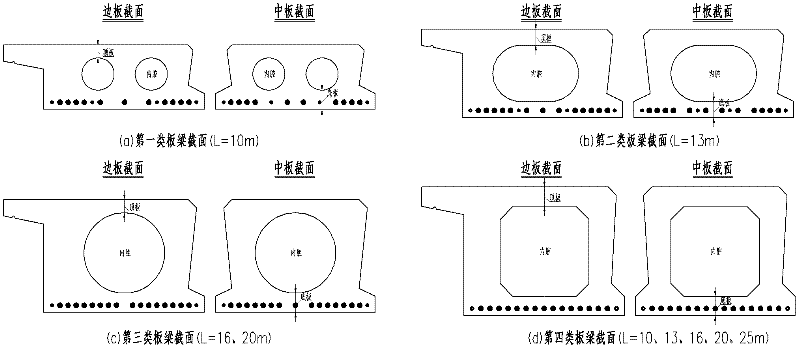

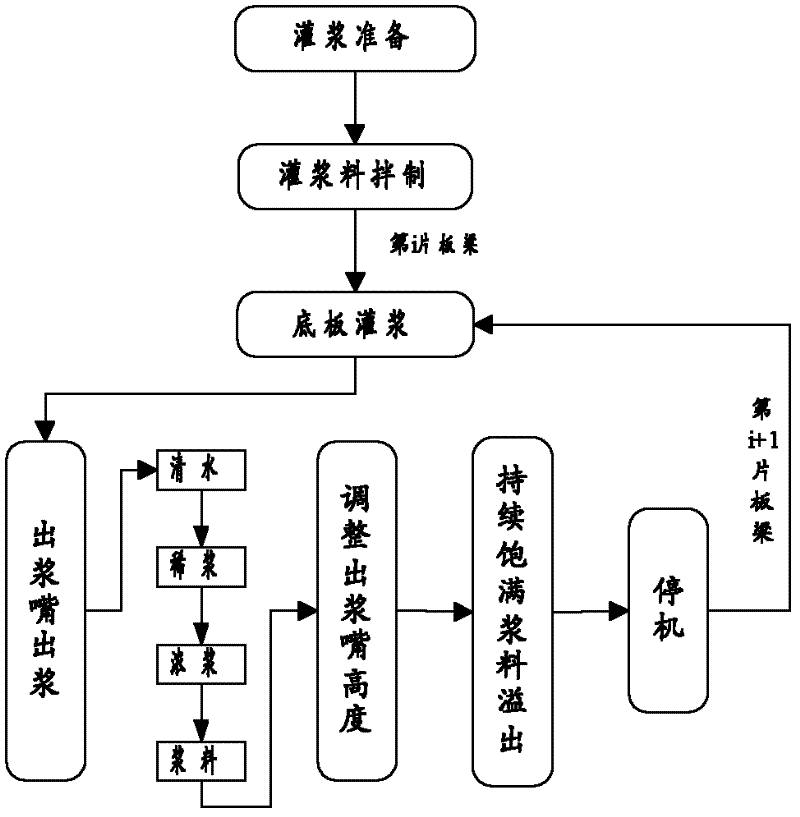

[0176] The bottom slab grouting construction is carried out on the 3×13m prestressed concrete simply supported hollow slab bridge, the longitudinal slope of the bridge is i=0%, and the section of the hollow slab is figure 1 The second type of plate girder section. The specific grouting reinforcement methods and construction techniques are as follows:

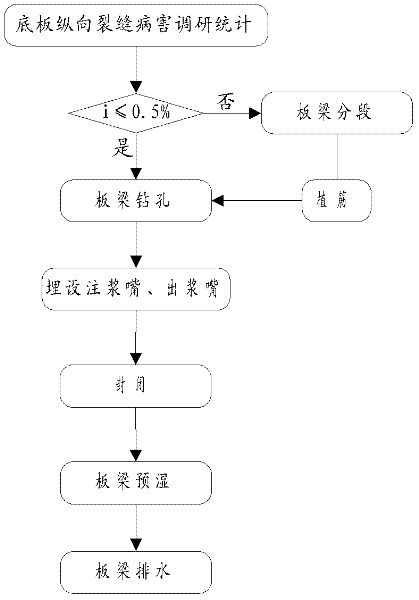

[0177] 1. Carry out inspection and research on the longitudinal cracks in the bottom plate of the bridge. According to the distribution of longitudinal cracks in the bottom plate and the severity of the disease, it is determined that the number of prestressed hollow slabs to be reinforced is 4 pieces;

[0178] 2. For each prestressed hollow slab to be reinforced, drill holes at the thinnest part of the slab girder floor at a distance of 50cm from the end of the slab girder and at the mid-span position of the slab girder. The diameter of the hole is 3.0cm. The total number is 12, and the drilling position of each prestressed hol...

Embodiment 2

[0190] The bottom slab grouting construction is carried out on the 1×16m prestressed concrete simply supported hollow slab bridge, the longitudinal slope of the bridge is i=1.5%, and the cross section of the hollow slab is figure 1 The third type of slab beam section. The specific grouting reinforcement methods and construction techniques are as follows:

[0191] 1. Carry out inspections and investigations on the longitudinal cracks in the bottom plate of the bridge. According to the distribution of longitudinal cracks in the bottom plate and the severity of the disease, it is determined that the number of prestressed concrete hollow slabs to be reinforced is three;

[0192] 2. According to the longitudinal slope i=1.5% of the prestressed concrete hollow slab bridge to be reinforced and the limit value of the grouting height difference between the low and high points of the floor [Δh]=5cm~10cm, determine the segmental grouting length L according to formula (1-2) k = 500cm. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com