Triangular concrete thin-wall folded plate pile and preparation method thereof

A concrete and triangular technology, which is applied in sheet pile walls, excavation, construction, etc., can solve the problems of difficult construction quality assurance, low energy of pile drivers, and high price, and achieve easy guarantee of pile quality, small energy of pile drivers, and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

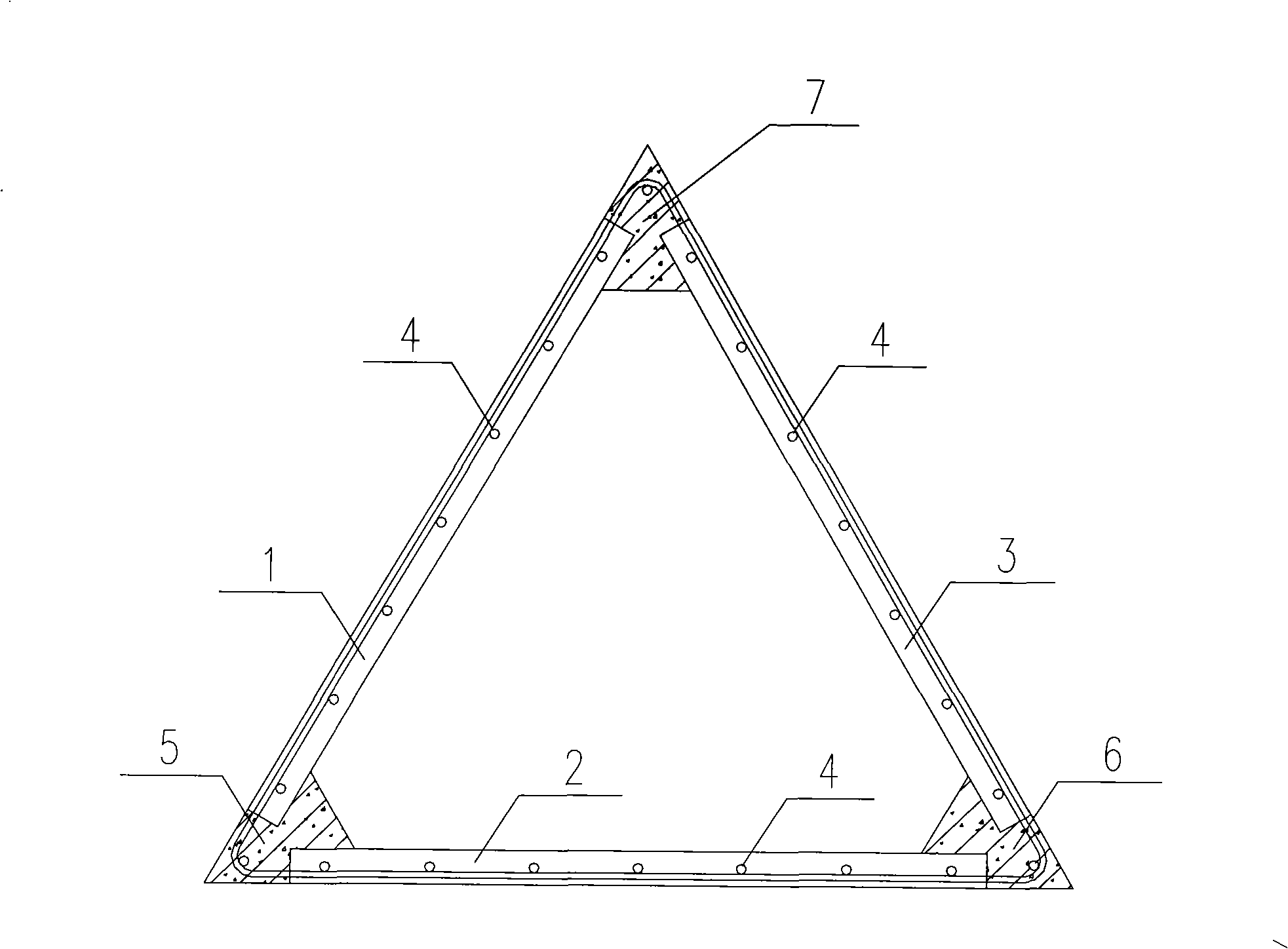

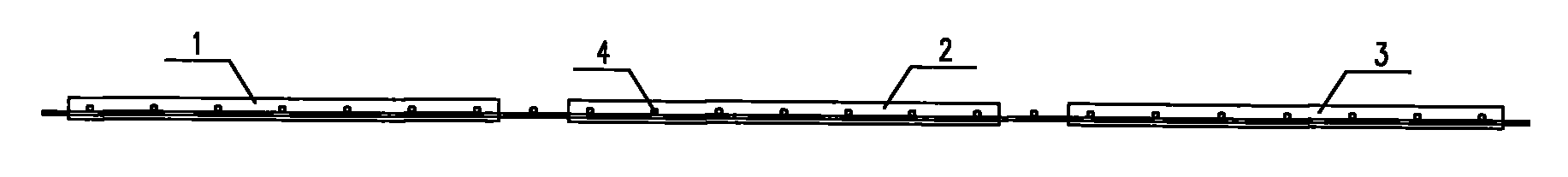

[0045] A triangular concrete thin-walled folded sheet pile, comprising: steel mesh 4, the steel mesh 4 is connected end to end to form a triangular tube shape, and the three surfaces of the triangular tube are respectively provided with a concrete left plate 1, a concrete middle plate 2 and a concrete The right plate 3 is respectively provided with the first bottom corner concrete belt 5 and the second bottom corner concrete belt 6 at the two bottom corners of the triangular tube, and the steel bars of the two bottom corners of the steel mesh 4 are respectively Covered by the first bottom corner filling concrete belt 5 and the second bottom corner filling concrete belt 6, a top corner filling concrete belt 7 is provided at the top corner of the triangular tube, and the steel bar at the top corner part of the steel mesh 4 It is covered by the joint-filling concrete belt 7 at the top corner.

Embodiment 2

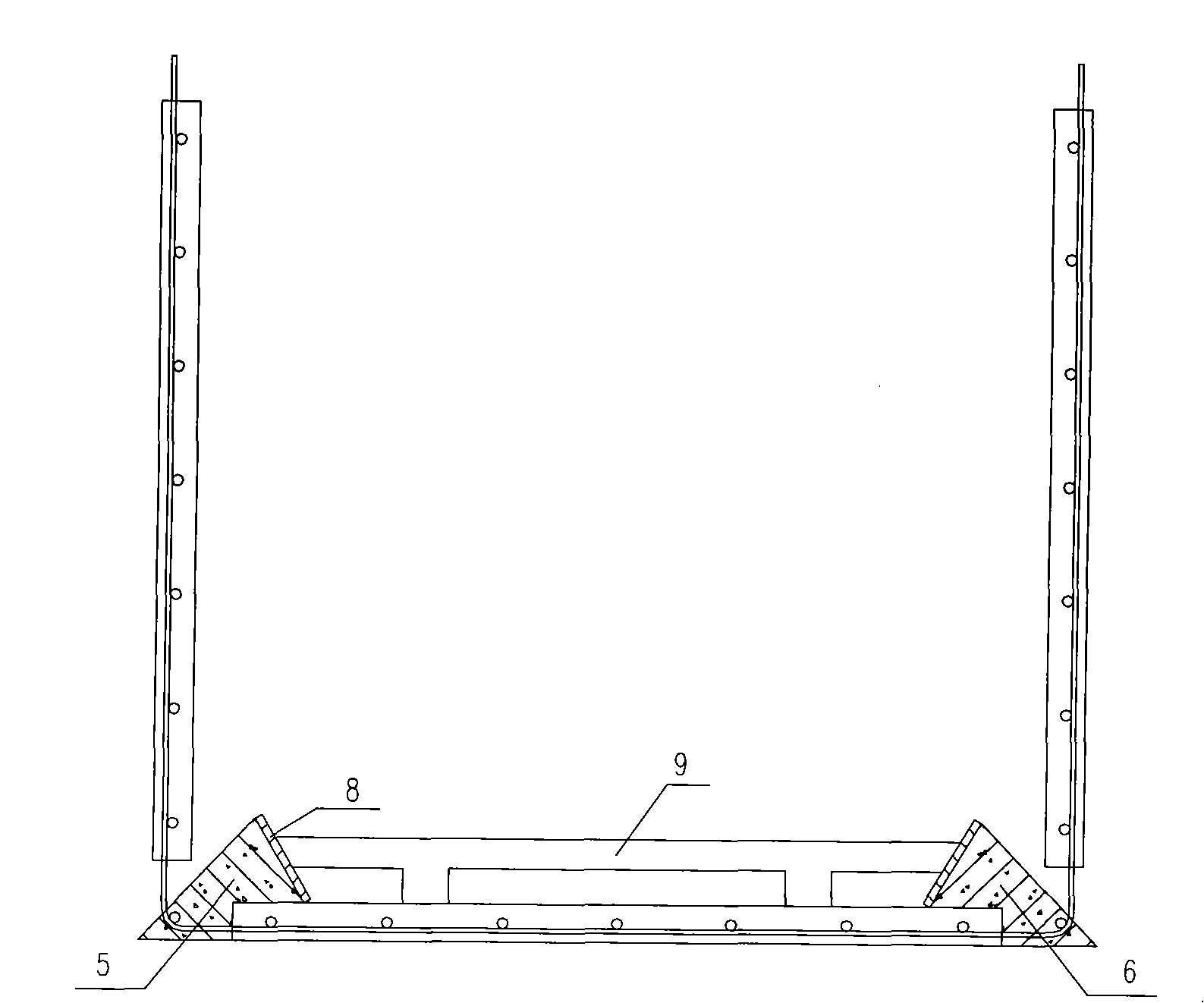

[0047] The triangular concrete thin-walled folded sheet pile of the present invention comprises a concrete left plate 1, a concrete middle plate 2, a concrete right plate 3, a steel mesh 4, a first bottom corner joint-filling concrete belt 5, and a second bottom corner joint-filling concrete belt 6 , Concrete belt for filling joints at the top corner 7, inclined wooden formwork at the bottom corner 8, paired wooden strips at the bottom corner 9, short welded connection bars 10, hanging formwork boards at the top corner 11, short steel bars and hanging wires 12, concrete installation pads 13, Plastic wedge-shaped positioning block 14, temporary installation section steel positioning bracket 15.

[0048] First level the site, measure and stake out, apply release agent, set protective layer pads, and bind steel mesh 4. Install the lateral formwork, and pour the concrete left slab 1, the concrete middle slab 2, and the concrete right slab 3 at the same time to form three reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com