Four-tube conjoint chimney

A chimney and conjoined technology, used in building types, buildings, towers, etc., can solve the problems of high construction cost and large amount of steel used in the steel inner cylinder, and achieve the effect of reducing construction cost, consistent bending stiffness and reasonable force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

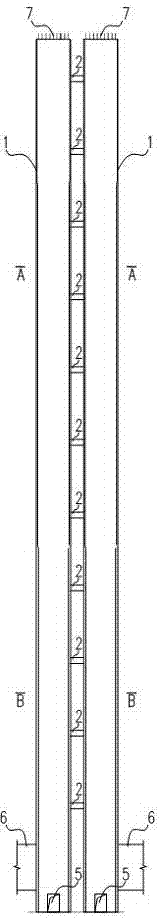

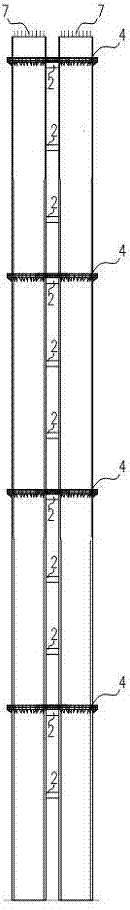

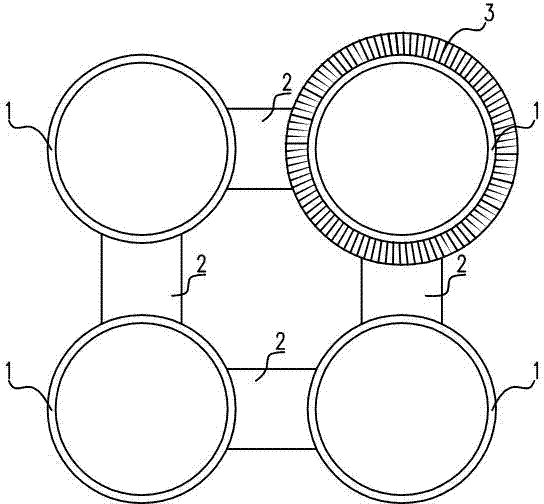

[0026] A four-pipe conjoined chimney, comprising a circular cross-section reinforced concrete cylinder 1 and a reinforced concrete tie beam 2, the four circular cross-section reinforced concrete cylinders 1 are arranged along the four vertices of a square, and the two adjacent cylinders 1 They are connected with reinforced concrete tie beams 2 along the height direction; the wall thickness of the circular cross-section reinforced concrete cylinder 1 gradually increases from top to bottom along the height direction of the chimney; its outer diameter and inner diameter are also along the height direction of the chimney from top to bottom Gradually increase; every two adjacent circular section reinforced concrete cylinders 1 have at least one reinforced concrete connecting beam 2 at the same level; every two adjacent circular section reinforced concrete cylinders have a connecting steel ladder 31; the connecting steel ladder 31 connects the connection points of two circular cross-...

Embodiment 2

[0028] Further optimization, the reinforced concrete connecting beam 1 is cross-shaped, and each end point of the cross is connected to a circular section reinforced concrete cylinder 1; the distance between the outer wall of the circular section reinforced concrete cylinder 1 and the center point of the cross-shaped reinforced concrete connecting beam 2 The smallest horizontal distance is equal. The overall outer diameter of the four-pipe conjoined chimney gradually decreases from bottom to top, and the four independent circular cross-section reinforced concrete cylinders 1 are integrated through the cross-shaped reinforced concrete connecting beam 2, which is larger than a single vertical chimney. stability.

[0029] The circular section reinforced concrete cylinder 1 is a reinforced concrete structure. The radius of the cylinder can be calculated by referring to the traditional multi-pipe steel inner cylinder chimney of the unit of the same level, and taking the chimney out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com