Prefabricated reinforced concrete odd-shaped cross-section pile

A special-shaped section pile, reinforced concrete technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of small pile side friction, not too large cross-sectional area, small cross-section stiffness, etc., to achieve large pile side friction. resistance, large economic and social benefits, and the effect of large horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

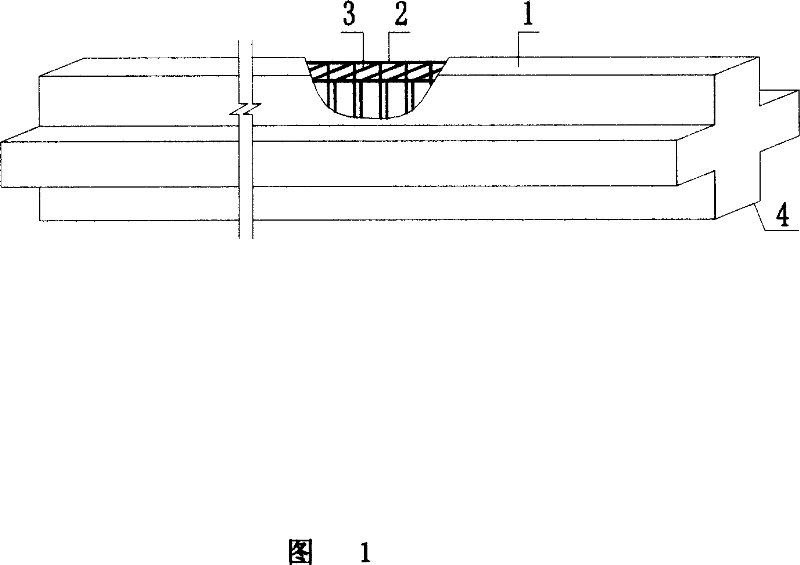

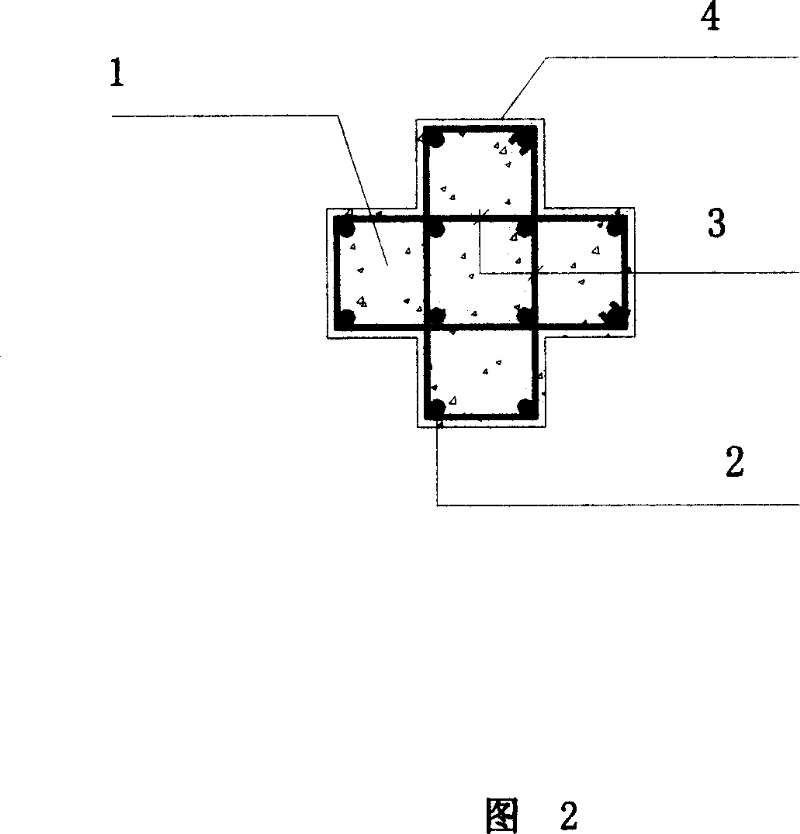

[0015] As shown in Figure 1, the main bars 2 are arranged in a single row, and the main bars 2 and the stirrups 3 are bound by iron wires (not shown in the figure) to form a reinforcement cage. The main bars 2 and the stirrups 3 can be ordinary steel bars or prestressed steel bars . After the concrete 1 is poured, a prefabricated reinforced concrete special-shaped section pile is formed. Concrete 1 can be ordinary concrete or high-strength concrete. Concrete 1 can also add various additives, such as reinforcing agent, early strength agent, water reducer, and anti-crack fiber products, fly ash instead of part of cement. Section 4 is "ten" shape.

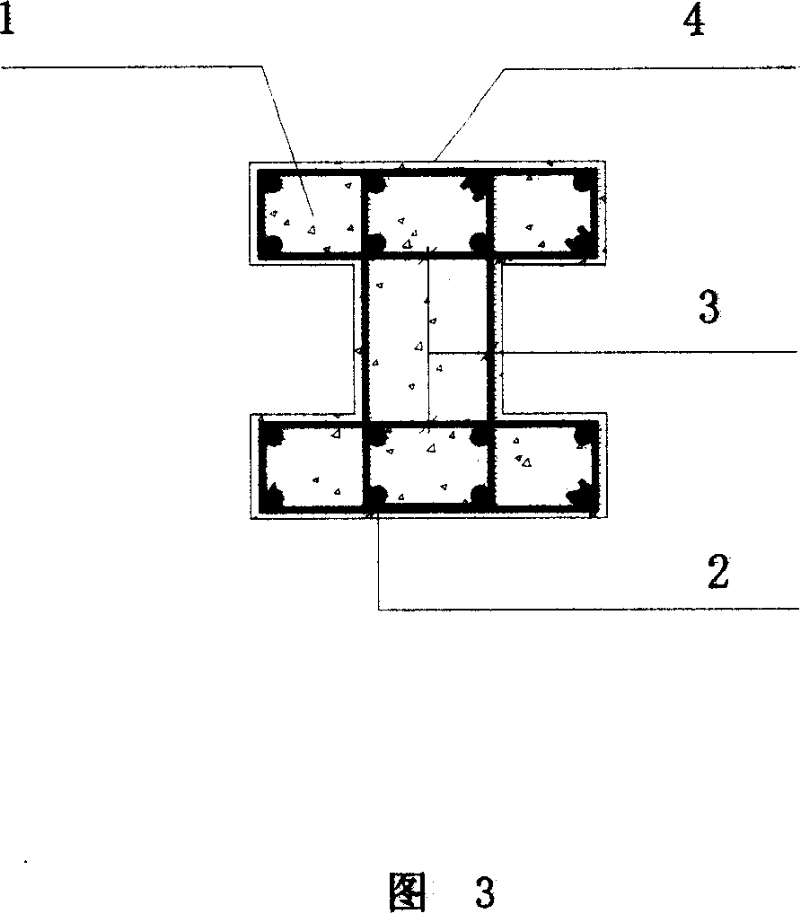

[0016] As shown in Fig. 3, the section 4 is in the shape of "I", the main reinforcement 2 and the stirrup 3 are bound by iron wires (not shown in the figure), and the concrete 1 is poured.

[0017] As shown in FIG. 4 , the section 4 is gear-shaped, the main reinforcement 2 and the stirrup 3 are bound by iron wires (not shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com