Bamboo-steel fiber reinforced concrete composite beam

A technology of steel fiber reinforced concrete and fiber reinforced concrete layer, applied in joists, girders, trusses, etc., can solve the problem of insufficient anti-sliding stiffness, achieve good shear performance, improve section flexural stiffness, and large section stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

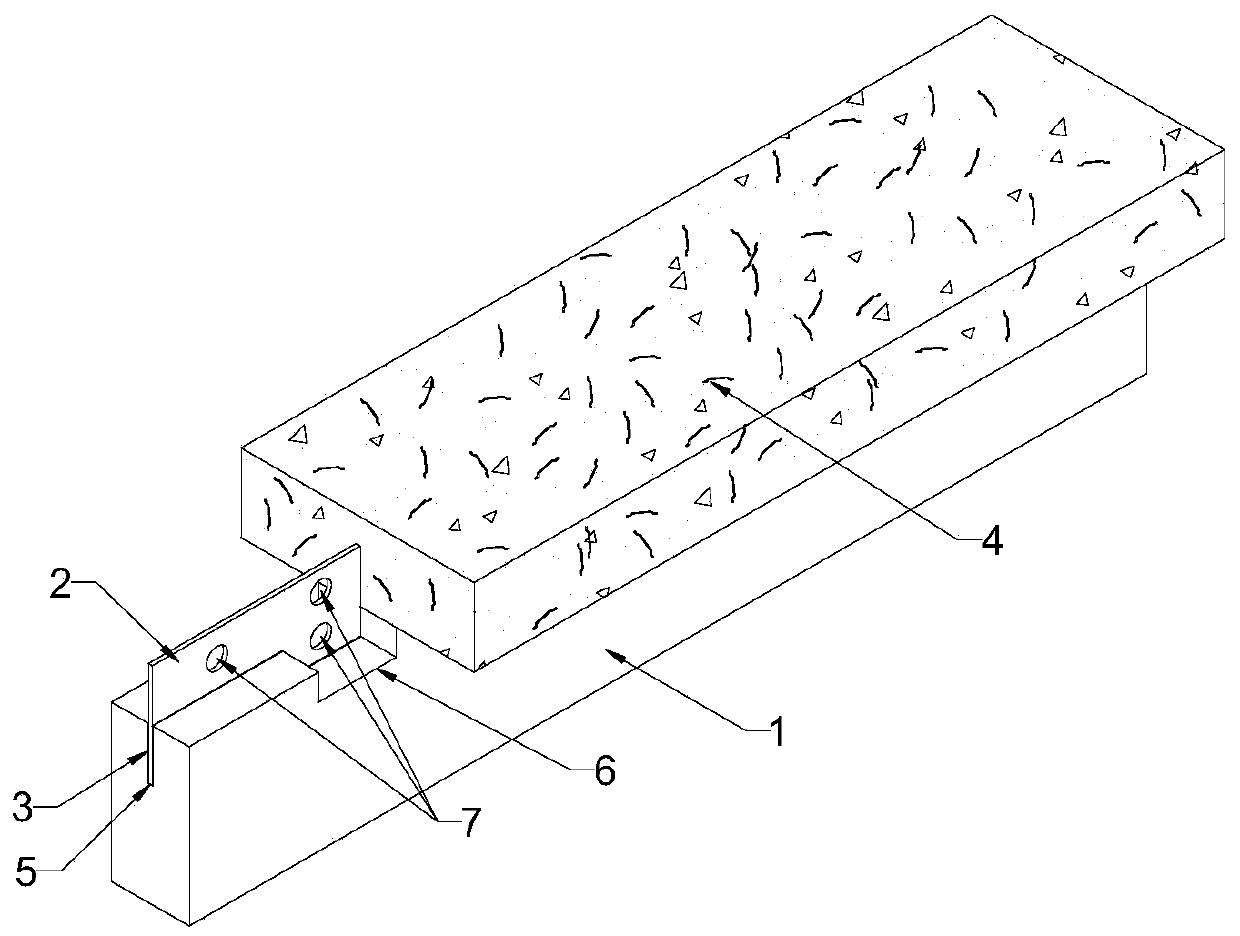

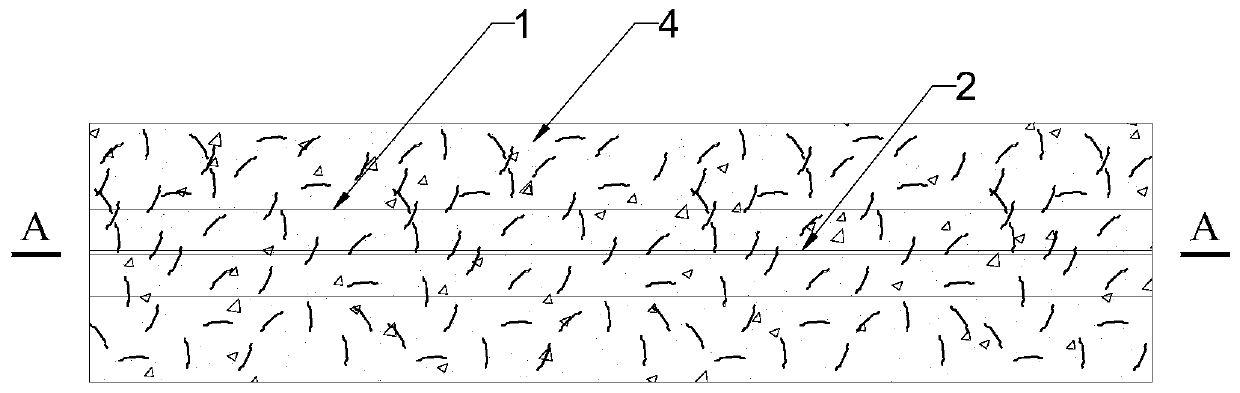

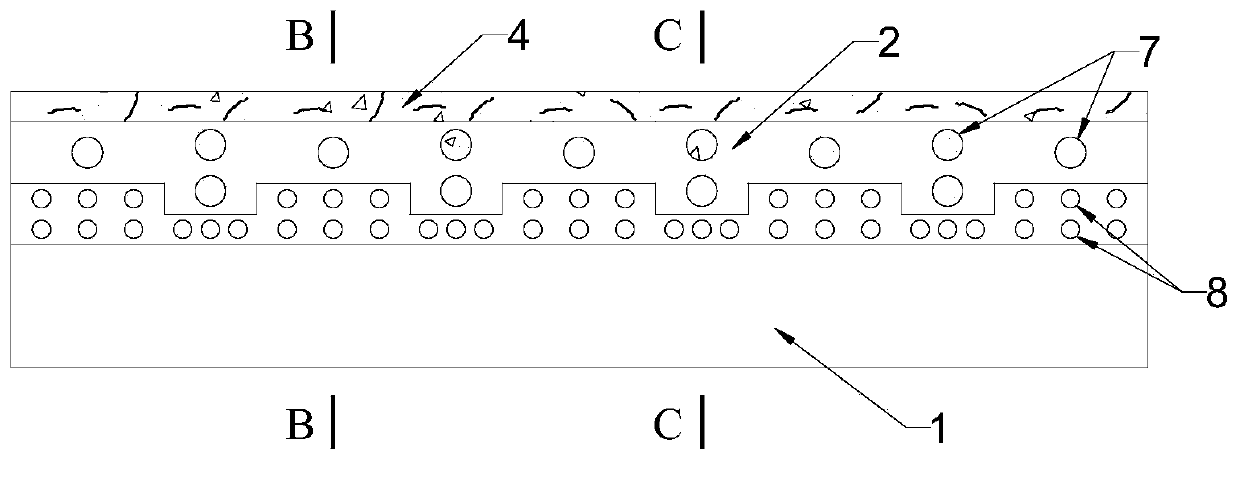

[0025] Such as Figure 1~5 As shown, a bamboo-steel fiber concrete composite beam includes bamboo beam 1, perforated metal plate 2, adhesive glue 3 and cast-in-place steel fiber concrete layer 4, bamboo beam 1 is provided with a reserved seam 5 along the length direction The bamboo beam 1 and the cast-in-place steel fiber concrete layer 4 are connected through the perforated metal plate 2, the lower part of the perforated metal plate 2 is embedded in the reserved joint 5, and the upper part of the perforated metal plate 2 is embedded in the cast-in-situ steel fiber concrete Layer 4, the upper and lower parts of the perforated metal plate 2 are respectively provided with a circular upper hole 7 and a lower hole 8; the adhesive 3 is filled with the reserved seam 5 and the lower hole 8 of the bamboo beam 1, and cast-in-place steel fiber concrete The layer 4 and the adhesive glue 3 respectively form an upper pin 9 and a lower pin 10 in the upper hole 7 and the lower hole 8 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com